Community Tip - Did you get an answer that solved your problem? Please mark it as an Accepted Solution so others with the same problem can find the answer easily. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Repeat region not working

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Repeat region not working

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Repeat region not working

I have an inexplicable problem. It makes no sense at all. I have an assembly drawing with a repeat region table, one based on a template I have used for years, and it is returning the wrong value for one component of the assembly in the "&rpt.qty" column. I have quadruple checked. The assembly has only one of these components in it but is showing up as 2 in the table. I have 4 other very similar assembly drawings and they show one of the component.

When I do an Info>Bill of Materials I get one. I pull in a new table from my standard template and it shows up 2. I suppress the part and it goes away from the table. I resume it and I have 2 again. What the heck?

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

Solved! Go to Solution.

- Labels:

-

Assembly Design

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

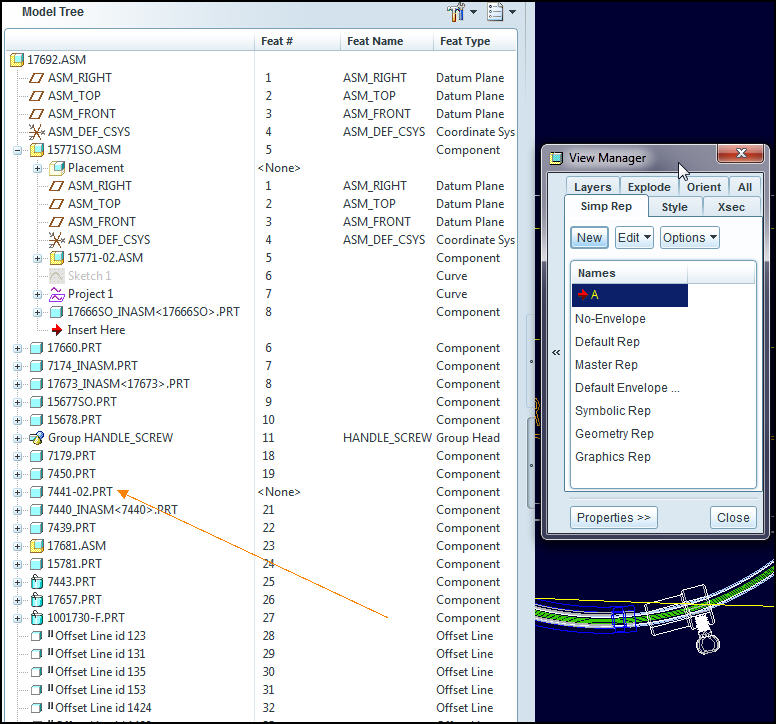

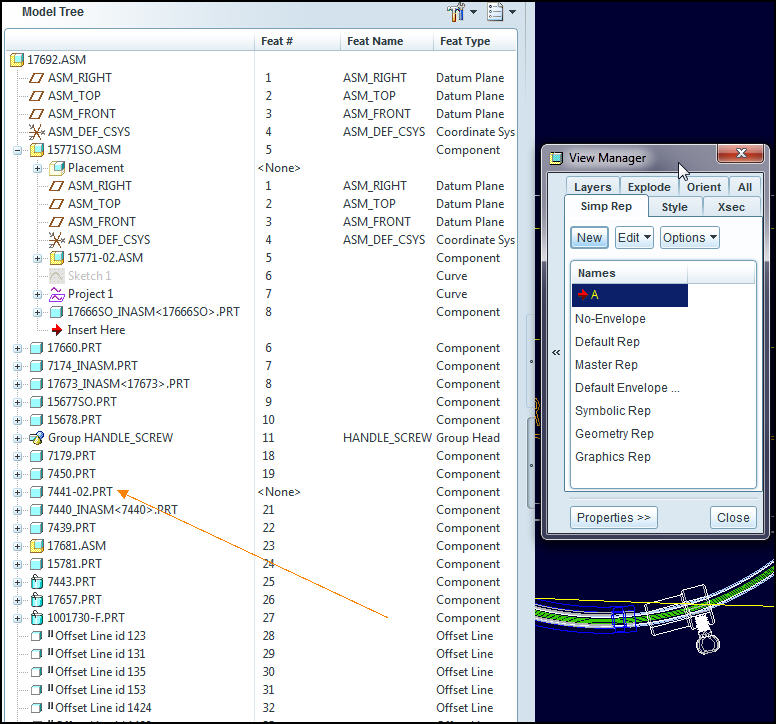

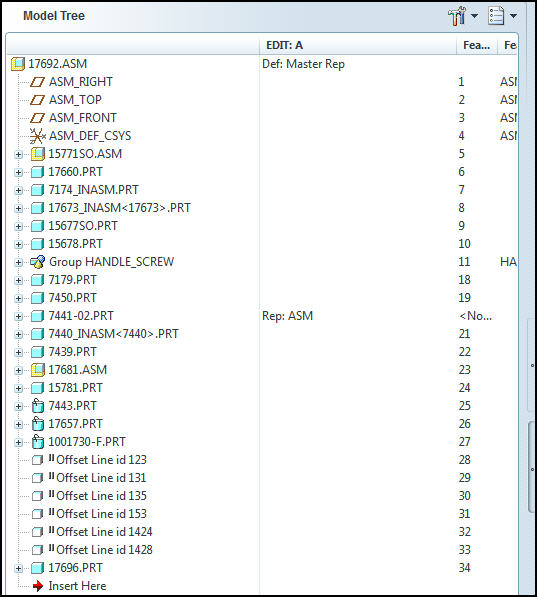

So... this is what I discovered. The assembly that is used in the drawing is a Simplified Rep, "A". I don't know why, this drawing was made before I worked on it. The Rep doesn't exclude anything. BUT... the offending part is supposedly excluded. When I open the assembly the tree shows it thusly:

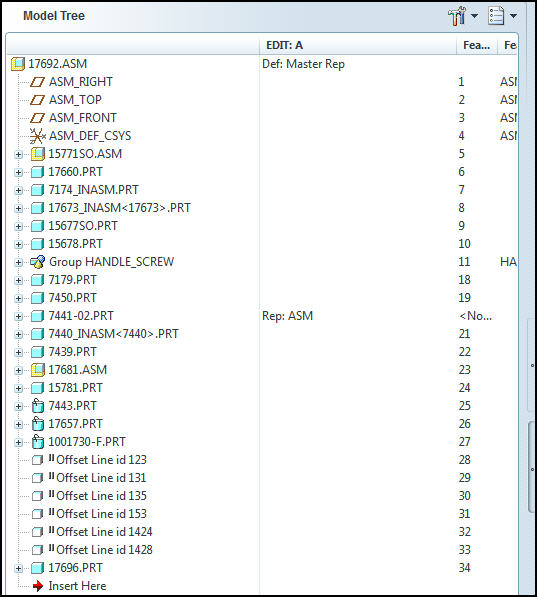

It says "None", but the part is there in the assembly plain as day. When I go in to redefine the Simplified Rep it looks like this:

It wants to substitute a Simplified Rep called "ASM". When I open the offending part it has a Simplified Rep "ASM" on the part level. I know why this may have been there before, because I basically remade the entire model. (Someone else had created it - don't blame me!) The part originally had two versions in the same model, like a family table, except the person who did it made it like a Simplified Rep. Some feature were resumed for Rep "A", and other features were resumed for the Master Rep. That seems a strange way to do a model with variations, but what do I know, I have only been using ProE for 20 years.

Anyway, for some otherworldly reason doing this causes the component to return a value of "2" in the rpt.qty cell of the table. I just took the rep out of the part and made the offending part Default display in the Rep, and bingo! , now it's back to one where it should be.

I thought I had seen it all. There you go.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

A fellow user came across more puzzling case. The QTY balloon showed the QYT as 2, but the Repeat Region showed only one. As in your case, the assembly had only one of the miscounted component. The workaround was to split the balloon and then hide the second one. It allowed attaching the second balloon to the same component, so that was interesting. If the second balloon was deleted the drawing table would eventually be re-evaluated and report the balloon qty was changed from 1 to 2.

Had you mentioned it was a rpt.rel.qty, then I'd suggest looking at the repeat region relations, but that doesn't seem to be the case.

Make sure it isn't a recursive table when you expected a flat one.

The only other thing I would try is to create a new drawing and a new table and see if it is following the drawing around or is a failure in evaluating the assembly.

Other than that I don't know of a way to force the repeat region to mis-report, so I don't know how to stop it (relations aside)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I just created a new drawing, used the same assembly, and pulled in the same table. In this it is showing correctly as 1 item.

Bizarre.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Grahame,

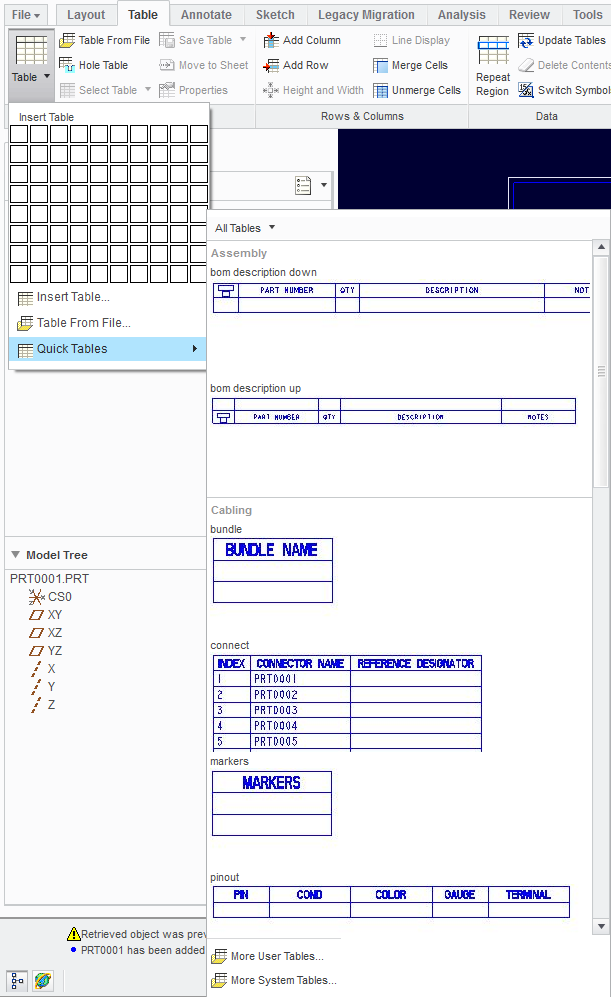

If you are on Creo 2.0 or higher, there are predefined tables with repeat region. Try to put one of these into the assembly drawing and see what you get.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

So... this is what I discovered. The assembly that is used in the drawing is a Simplified Rep, "A". I don't know why, this drawing was made before I worked on it. The Rep doesn't exclude anything. BUT... the offending part is supposedly excluded. When I open the assembly the tree shows it thusly:

It says "None", but the part is there in the assembly plain as day. When I go in to redefine the Simplified Rep it looks like this:

It wants to substitute a Simplified Rep called "ASM". When I open the offending part it has a Simplified Rep "ASM" on the part level. I know why this may have been there before, because I basically remade the entire model. (Someone else had created it - don't blame me!) The part originally had two versions in the same model, like a family table, except the person who did it made it like a Simplified Rep. Some feature were resumed for Rep "A", and other features were resumed for the Master Rep. That seems a strange way to do a model with variations, but what do I know, I have only been using ProE for 20 years.

Anyway, for some otherworldly reason doing this causes the component to return a value of "2" in the rpt.qty cell of the table. I just took the rep out of the part and made the offending part Default display in the Rep, and bingo! , now it's back to one where it should be.

I thought I had seen it all. There you go.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I've only had one reason to do this sort of thing - in a weldment that uses key/slot and alignment holes in matching parts, it seemed like it might be nice to eliminate the appearance of these features in top level assemblies. Since Simp reps seem to not care about assembly constraints, it seems like a useful thing to have the piece parts have Simp reps where the soon to be filled features are eliminated. Using flexible features won't work because the assembly constraints will no longer function. Plus I need the features to disappear in a skip-level fashion. Must be there for weldment, must not be there for higher levels.

I am annoyed by those who use Simp reps instead of Family tables as a replacement for Simp Reps. Simp reps aren't retrievable/traceable in Windchill; at least I can't tell Windchill to find the "TOP_LEVEL" Simplified Rep.

In your case, I would think it is a bug that is evaluating the assembly, finding the base component, and then also finding a link to the simp rep and seeing that as also the base component at the same level of assembly. Based on that supposition, if the part assembled more than once with Simp Rep substitutions, then you'd get 2X the number of assembled parts.

Either no one has called this in, or there's been a fix for it for a while and you need a later version of Creo.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It was a similar thing in this model. The part in question was a length of silicone tubing, which is very pliable. In the assembly the part was bent up into its final shape and was generated with a sweep. It's only purpose in the assembly is visual. The actual part is just called out as tubing cut to "x" length, so it also had a straight version of the same thing in the model. One was switched off and the other was switched on. The straight part wasn't actually used for anything so I deleted that part of it.