Community Tip - You can change your system assigned username to something more personal in your community settings. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: keep sum of distances constant

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Screenshots inside Creo

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Screenshots inside Creo

Greetings all.

Does anybody know if there is a way to take a screenshot inside of Creo within a window? I currently use the printscreen button and paste it into Paint. I then select the area I want and put that in an email. I am looking for a way to select a window in Creo and paste that into an email without having to use Paint.

Thank you in advance for your assistance.

Solved! Go to Solution.

- Labels:

-

General

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Then I'll go for a "reconciliation post" as answer, because it's probably least confusing in the unlikely case anyone happens to stumble across this 🙂

The workflow that works for me now:

I am creating auxiliary datum planes in each component that correspond to the positions of the "optically relevant" planes. These planes are the ones that would have to coincide if the microscope was build straight, and the distances of these planes will also be used to lock all of the relationships.

The folding mirrors will realistically be placed under an angle of 45 degrees only, so I'm creating auxiliary planes as well that correspond to the planes that the light path is located in before and after the reflection off the mirror. Since the mirror is at 45 degree, these planes will be at 90 degree to each other (and 45 degree to the mirror).

The distance between the relevant optical plane of the component just prior to the folding mirror, and the relevant plane in the mirror is then defined when setting the constraints during placement. The distance between mirror and the component behind the mirror has to be the negative of the distance in the first constraint, and so on, through the whole assembly.

The positive and negative distances are linked by defining

$dist_neg = - dist_pos

in the relations window.

It of course helps to rename the distances first: This can be done eg. by editing the feature (right-click in the feature tree and select the icon with the distance pictogram), then selecting the distance (it has to turn from yellow to red) and then right clicking to select "Properties".

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You can certainly use relations to set certain dimension values equal to something but I wonder if maybe mechanism connections would work better. You could make extra parts to represent the optical distance and then constrain the mirrors and these path parts with pin connections. This would allow you to move around the mirrors while always keeping them a fixed distance from each other (whatever length the distance parts are set to.)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The way I understand it, a pin connection would keep two points fixed to each other, but they could still swivel around one axis. That would certainly help to "pin" the light path to the mirror surface while the mirror is tilted, but could the optical path slide along the mirror when the mirror is moved?

Maybe a good mechanical analogon would be a rope of a fixed length that has both endpoints held fixed. The mirror surfaces would be like hooks that the rope can bend around/slide across as you change the position of the hooks/mirrors - while the endpoints stay fixed at all times.

PS: Please bear with me, I'm a complete noob using Creo, and the transition from Solidworks is harder than I had hoped ...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I would create a set of datum curves to represent the ray of light that is in the center of the optical path and use relations to control the path lengths. If these curves were in a skeleton part, the skeleton can be added to parts and sub assemblies as construction references to ensure consistency.

Since Dassault has put the Solidworks help files on line, perhaps you can point to the functions/features you would have used to create this. http://help.solidworks.com/2018/english/SolidWorks/sldworks/c_solidworks_fundamentals_overview.htm

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

So the source and target are fixed and the mirror moves and rotates?

Also, are you expecting dynamic movement of the mirror in the assembly or are you expecting to require a regeneration?

If you can set up a test case assembly and post it as a zip file, we could probably help with various solution.

Just let us know what version your files are from and if they are academic or not.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks everyone!

@TomD.inPDX: Actually, the statement that both of the rope's ends are fixed was imprecise: Both of the rope's ends are fixed to a part, but one of the parts is free to slide within the assembly. In principle, mirrors can slide and be rotated at any angle with the light beam bouncing off at the same angle as it's incident. Realistically, mirrors will only be placed under 45 degrees, resulting in the beams reflected at 90 degrees. The position of the mirrors will be static once the design is finalized, but during the design, I need to be able to move them around. Having to regenerate the model in between is completely fine.

I hope the set of test files helps to illustrate this: I included just three parts to illustrate the principle: two lenses (objective & tubelens) and one mirror, to illustrate the principle. Of course, there's going to be more parts in the actual microscope.

Created using Creo 3.0 academic.

Some explanation:

The objective is designed such that the origin of the part is the point that the objective is designed to look at.

The tubelens. Note that there are a number of datum planes in the tubelens, these correspond to important optical planes.

Microscope_Straight: When I assemble these two lenses only paying attention to the optical constraints, I start by placing the objective at the origin of the assembly. Then I make right and front planes of the tubelens coincident with right and front planes of the assembly. In the end, the tubelens front focal plane (FFP) is matched to the objective's back focal plane (BFP) - thus essentially fixing their distance.

Microscope_Folded: Now has the mirror between objective and tubelens. Note that I placed datum planes under 45 degrees in the mirror, to present the planes of the incoming and outcoming beams. It would also be possible to design the mirror at a 45 degree angle to the standard left right top planes, but usually I download .step files from the manufacturers, and it's easier to just create the extra planes.

The right plane of the mirror is coincident with the right plane of the assembly and one of the 45 degree planes coincident with the front plane. The other 45 degree plane is at a distance to the top plane of the hole assembly.

Similar for the tubelens: right planes overlap, top plane overlaps with one of the mirrors 45 degree planes, and FFP is parallel to the other 45 degree plane. The distance between these two planes should now be the negative of the distance between mirror and objective BFP.

I looked at relations as suggested by @dschenken, but did not see if I can enter the distances specified in a mate there. I did not try to model the light ray as datum curves yet. But maybe creating another auxiliar plane in each component, mating these planes as coincident, and then fixing the distances of these auxiliary planes to the optical front and back focal planes via relationships would work?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Any dimension can be set via relation. It helps to rename the dimensions under the dimension properties. So if there is a parameter "total_distance" and a dimension "lens1_to_mirror" the second dimension can be managed "mirror_to_lens2 = total_distance - lens1_to_mirror" causing the second distance and first distance to always add to total_distance.

It's possible there is a way to create a fake mechanism that will produce the desired relative motion so that the elements can be dragged, such as by a cam. The mechanism would not be part of the finished design; just a design tool.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

+1 ...I could not open the file since it is academic.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I'd reply to the thread, but I find it academic.... 🙂

Of note, where the h3ll did they put the evaluate feature?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I saw that coming a mile away, Frank!

What "evaluate" feature?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

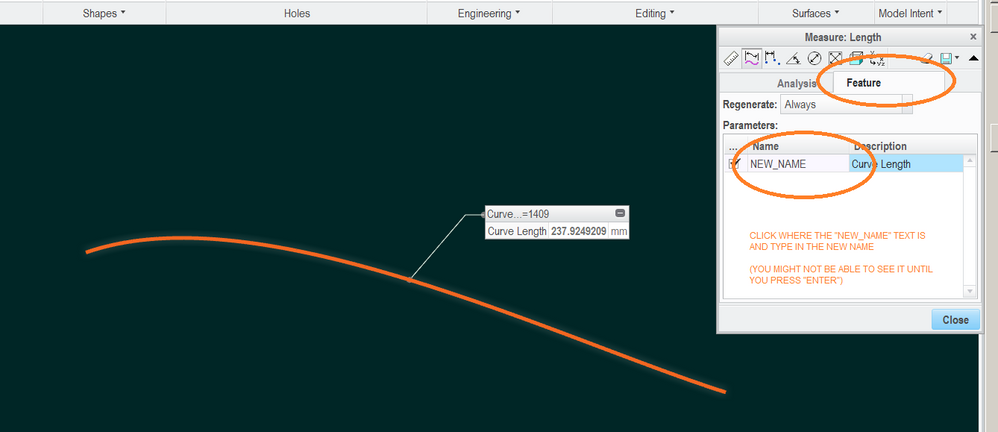

There was a feature where you could measure, say, the length of a spline (curve, edge, etc.) and it would make it a parametric parameter. You could then use this parameter to make, say, a straight line of the same length, that would change as the spline (etc.) length changed.

For instance, I had a hydraulic tubing routing I got to the length/curvature etc. I wanted at assembly, where it worked with all the motion of the parts and had what looked like the right about of slack. I made the evaluate feature for that spline length in the part, made an alternate straight trajectory of the same length in the part, and made a family table of that where for the drawing, the instance would be a straight line of tubing. This way if the routing (thus length) changed, the straight length in the dwg changed accordingly so they could procure (or cut) the right length. Now I can;t find that evaluate feature.

I also used it to drive spinal bends to make the straight length of something equal to the curved length.

Now I can't find that feature. It was probably deleted or hidden like the N-Sided mesh as an "upgrade!".....

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

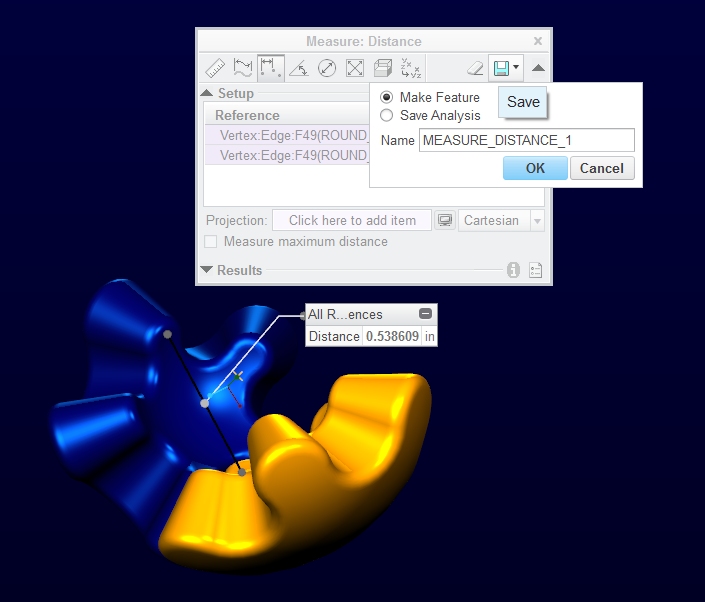

Ah, yes, that is the "Measure" function that can make a parametric feature of the calculated value.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I THOUGHT that's what they did, but haven't been able to access it or make it work. I'll have to play with it more. If I can get it to work, it'll be easier than it used to be, so that'd be nice.

That is one nice thing in NX, where if you measure something (length, diameter, etc.), and check the box for "Associative" it creates a parametric feature with a dimension (PXXX where in creo a dimension is dXXX) that you can use in "expressions" (their version of relations).

Now I'm curious why I wasn't able to get it to work,,,

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Same in Creo... just "Save" the measurement in the dialog and you get more options.

At that point the measurements become accessible parameters.

And you get a "feature" in the tree so you can edit it 🙂

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hmmmm, I tried that and no feature showed up in the tree. I'll play with it some more.

Nice gears! 🙂 I think I found an easy way to get true involutes without having to mess with CS's and equations etc. Just haven't had the time to play with it yet....

Grazie!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

There is probably a tree filter that needs to be changed to see the feature.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Ah, ok, I finally got it. Grazie! I was using "Save Analysis" instead of "Create Feature". I like this new functionality (oddly enough, like NX) better than the old functionality. Once you know where the button is, it's easier to create than the old "Evaluate Feature", even if it has a little less functionality (can't name the parameter what you want, only the feature name - that sux!). And actually, I have to say, NX's functionality is much better, as it creates a dimension (Pxxx) that you simply reference in the dimension modification box of your straight line (or whatever) instead of having to write a relation and do the whole "d389 = LENGTH:FID_MEASURE_LENGTH_1" thing. STILL requires a second regeneration to force a straight line to the developed length of a 3D curve though, so that's still maddening as ever. When is PTC ever going to change THAT???

It turned out not to be a "filter" issue.

I'd like to get some formal training on creo 3 so I know where they moved all the buttons from Pro 5.0 (worst EVAR!), but it seems that's probably not going to happen so I'll just have to wing it.... 🙂

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It was a user filter issue.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Interesting, it wasn't for me. I just had the wrong box checked.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The -user- filter. PEBKAC.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

LOL Had to look that up. 🙂

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

One thing is that you can name the parameters of the analysis feature, like so:

(Creo 2.0 - maybe this "easter egg" has been fixed since then...)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I managed to set the relations, and moving the mirror now moves the tubelens as well, awesome!

However, I'm utterly failing to identify where to rename the relations ... from the tutorial, I see that it should be in the context (right click) menu of that dimension. I tested with a dimension in a sketch (sanity check), but don't see a properties entry (I put screenshots here: https://seafile.ist.ac.at/d/5ab0495fa5f842d19a41/, because I'm pretty sure that I'm just somewhere still in the wrong context).

To rename (or first: view) the distance of the constraints, I

1) right clicked the "placement" entry under the part entry in the model tree and selected "reference viewer", but cannot find where to rename the dimension there (screenshot).

2) right clicked the actual constraint under placement --> set# --> distance and under information --> feature information clicked the features dimension to highlight it in the drawing. Right clicking the dimension there provides only "repeat" and "information" in the context menu.

3) I made the component flexible, select the correct constraint. Then I'm able to see the value of the dimension, but still no luck in renaming it from the context menu (screenshot).

So: where do I find this dimension properties?

Also, dragging a mirror is a pain: I am highlighting the part, click Component --> make flexible, have to confirm, then select the placement tab, select the correct constraint and can then change the value. There has to be a better way ( = less clicks), but how?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Relations have their own dialog. Also find the "switch symbols" button so you can identify the dimensions you want affect.

Also know that you apply relations at several levels. By default, relations in a sketch with remain "section relations" where prompted relations go to the top level. I try to keep relations related to the feature whenever I can. Also know that parameters are not relations. Parameters are the values; relations is the math.

Allowing a regeneration between moves is the easy way for sure. This allows for a lot of solutions depending on your end goal. Most of us try to make movement dynamic but this is more challenging as was pointed out before.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

+1 for the "switch relations" button 🙂

Is there any "all the dirty tricks you need to know for Creo" book/tutorial? I mean, the tutorials are helpful, but they seem to show you only how to do everything in the correct order. What I'm missing is information along the lines "how do I get back into this and that menu when I closed it too early or when I want to change anything later on".

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

That's not what 'make flexible' is for. It is to override whatever was purposely defined in a subassembly or part.

The relation is not in the dimension, the dimension name is in the feature dimension properties. Modify the feature and select the desired dimension on the screen. Then right click should have 'properties'.

Sketch dimensions have no properties; only feature dimensions have properties. The value of the sketch dimension is shared with the feature dimension that results from using the sketch to create a feature, but feature dimensions have tolerances, names, other characteristics.

The relation is usually in the part/assembly. Relations can be created in the context of the sketch, but that makes them awkward to modify.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Works. Selecting the component and then selecting the value of the dimension before I get the right context window was one click too much 🙂

I'll still have to play around of course to find an optimal workflow, but I'm happy for now with setting the distances of the auxiliary planes via relations, since I'm creating those planes anyway.

Are there any "rules of conduct" as to which answer I should accept as solution, since there were a number of contributions required?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Well, if you always accept Tom's or my solution as the solution, you can't go wrong! LOL 🙂

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Are there any "rules of conduct" as to which answer I should accept as solution, since there were a number of contributions required?

There isn't one that I know of.

However, know that a consolidation post by you can also be marked as correct.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Then I'll go for a "reconciliation post" as answer, because it's probably least confusing in the unlikely case anyone happens to stumble across this 🙂

The workflow that works for me now:

I am creating auxiliary datum planes in each component that correspond to the positions of the "optically relevant" planes. These planes are the ones that would have to coincide if the microscope was build straight, and the distances of these planes will also be used to lock all of the relationships.

The folding mirrors will realistically be placed under an angle of 45 degrees only, so I'm creating auxiliary planes as well that correspond to the planes that the light path is located in before and after the reflection off the mirror. Since the mirror is at 45 degree, these planes will be at 90 degree to each other (and 45 degree to the mirror).

The distance between the relevant optical plane of the component just prior to the folding mirror, and the relevant plane in the mirror is then defined when setting the constraints during placement. The distance between mirror and the component behind the mirror has to be the negative of the distance in the first constraint, and so on, through the whole assembly.

The positive and negative distances are linked by defining

$dist_neg = - dist_pos

in the relations window.

It of course helps to rename the distances first: This can be done eg. by editing the feature (right-click in the feature tree and select the icon with the distance pictogram), then selecting the distance (it has to turn from yellow to red) and then right clicking to select "Properties".