Community Tip - Did you get called away in the middle of writing a post? Don't worry you can find your unfinished post later in the Drafts section of your profile page. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Setting an absolute retract height

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Setting an absolute retract height

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Setting an absolute retract height

Hi there people! I'm having a bit of trouble with something that should be fairly easy. Basically im machining a block that is at the limits of the machine travel in Z. The tools only have 4-6mm clearance above the top of the block before the machine runs out of travel.

So I set my retract plane for my operation to be 2mm above the surface of my block, but when I machine on an angle the tool tries to sometimes retract past this point and ends up overtravelling. I've had to be manually changing them after posting and was wondering if theres a way to tell creo that you dont want the tool to retract past the Operation retract plane, no matter what angle it is on.

- Labels:

-

Surfacing

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I would check each sequence and verify that the retract plane of the individual sequences are not higher than the operation retract plane. The machine will still go to the z level of the sequence if it is higher than the operation retract plane.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

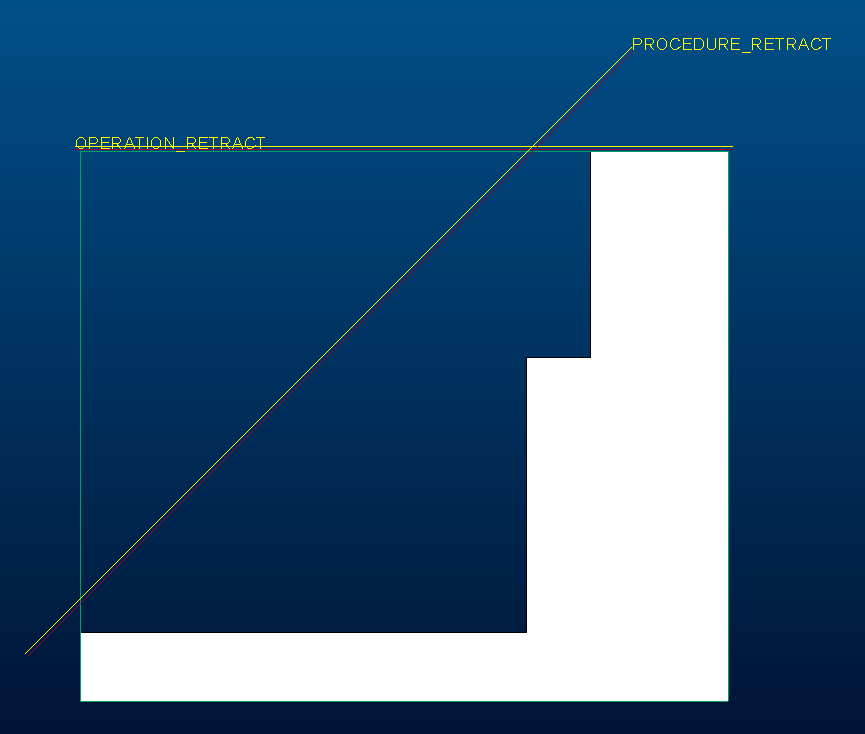

The problem im having is that when you have a sequence retract plane at an angle of say 45 degrees, it will go above the operation retract plane at some points.

Eg:

I just want to know if theres a possible way to limit the procedures retract plane once it hits the operation plane. The operation plane should be a limit of the height you wish to retract to. Is there any way at all to tell Creo not to go above a certain height?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Operation retract geometry (not necessarily a datum plane) is used to traverse between sequences, but it does not work as an overall limit to what happes within sequences. So sequences can exceed it.

You may add some limits inside sequences by using check surfaces, but these will be usable only as boundaries to the side, because otherwise the algorithm tries to approach them from the top rather than from below.

In your example, if you add a check surface coincident with the operation datum plane, the tool would rather try to stay on top of this plane and not go down to the material.

But you could prevent the tool to overtravel the point where the two planes are intersecting, when you create a check surface normal to the PROCEDURE_RETRACT along this line.

(don't know whether this is of any help to you)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Try changing your operation retract from a plane to a cyninder.