- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: So, they want me to learn SolidQuirks.....

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

So, they want me to learn SolidQuirks.....

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

So, they want me to learn SolidQuirks.....

Honestly, the way PTC has completely dropped the ball when it comes to getting Pro/E into colleges is the main reason. One of the reasons the SW users hers (who never actually really put forth any effort to LEARN Pro/E) are pushing for it is the lack of Engineers who can use Pro/E fresh from school. I'd rather them hire experienced Engineers, but maybe that's just me....

So, I think it will look good on MY resume, so I'm going to put effort into learning it. I will give it a fair evaluation after I've learned enough about it's capabilities, though I will say it will probably be very much like friends who are very experienced users in both and in general are saying. We'll see. There are some things I like about SW from what I saw already. I'm curious about the GUI's all the i-phone kiddies seem to love......

And, from seeing their work, I'm sure I'll be more fluent in SW than they ever became in Pro/E.....and I'm also sure I'll even be better in SW than any of them. Only one of them even remotely impresses me in SW.

So, my questions to those who use both is:

1. What should I expect?

2. What are the shortcuts/tricks?

3. What is the easiest/best approach to learn it quickly and fluently?

4. Using surfacing and the advanced features like I do, what are the comparable features and building methods in SW?

Anything else you think I might want to know.

Grazie!

Stay tuned dear friends! ![]()

Solved! Go to Solution.

- Labels:

-

Surfacing

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Being the big dumb welded million pound structure guy, it's looks perfect to me!! You guys and your sexy curves!!! Straight is BETTER and PLEASE give me some 90° corners so I can have a good starting point!!!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Beware the Straight Line, Mr. Williams....beware!!!!!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It's the Arc table by Molteni:

The base is cement, probably cast.

More images on Google:

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I would have guessed a cast material, plastic (RIM'd) or bronze, though I can see it being made of concrete. I'd hate to have to move it! My old roomie had a large dining room table that had cast iron figures for the corners. That was the heaviest thing I ever tried to move....well, besides a piano.....and we gave up on the piano!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

They have 2D DWG downloads and you can email them for a 3D CAD download. I've downloaded the DWG and requested the 3D, we'll see if I get it.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I've just re-activated my SW license after 3 years. Crew just doesn't seem to move on and everything is another "paid module". Its easy for me to see why people are migrating to it I'm afraid. PTC just seem happy to send out endless videos of the CEO etc whilst Dassault send out tips and tricks tutorials that actually help.

I did a three day intro, and what was clear it that SW is intuitive, you spend more of your time doing the engineering / inventing / design as opposed to learning the system.

I've been using ProE then Creo as a product designer for about 15 years, and I still feel it is the most unintuitive CAD package I've ever encountered. Just try copy and paste in a drawing as the most basic example - why does it feel like something from the 1980s, well, perhaps because thats when half of it was written.

Good luck with SW, I think you will like it.

Stephen

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I guess I use mapkeys so much I don't see anything more "intuitive" about SW compared to that. At first, back on V15 it was somewhat difficult to wrap my head around, but that old menu manager actually made sense, more than Wildfire, and certainly more that creo, but it was a little cumbersome. Then again, I LOVED using a UNIX box (Silicon Graphics Indy) to run it.

It seems the power I'm used to is somewhat or seriously diluted in SW (no trajpar, not graphs, no multi-set rounds, etc.), and for me that's the #1 issue I would have against it.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I suppose by "intuitive" I don't mean customisable, I mean discoverable and logical, such that when you attempt to do something for the first time, the chances are, you get it right, not at the tenth attempt I'm still wondering why the UI is so utterly confusing, why text is truncated, why I'm dealing with an interface where there are three separate menus to set an appearance for example.

Ive found for example just creating a general Arrangement drawing, its easier to export from Creo (that I've used for many years) and import a STEP file into SolidWorks and create a sensible looking drawing with a BOM table in a few minutes in a package I hardly know that needed special macros / template files from my tech support etc etc in Creo.

As you rightly say, this sang on am SG Indy box compared to the completion back then. It now feels a bit like windows 10, they've focussed on a glossy top coat, but under the surface you soon expose the ancient foundations.

I'm sure I will continue to use Creo, but I've seen the Industrial Design studio I work in gradually transition to SW as its just so much easier to learn and seems quicker to use, as a colleague who uses Creo put it, "I feel like I've been given a cart horse and everyone else is on a racehorse". Its powerful for sure, but that's not the whole picture. From no seats of SW and 4 of Creo to 10 of SW and two unused Creo seats in 5 years I think tells the story.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Sooo, my new boss, the one who wants us to convert to SW so badly, had MCAD come in for a demo today. Prior to this, I sent them some surfacing files and other models to try and reproduce. The guy who came in, showed a new model containing my model (brought in as a STEP) and one next to it he did in SW and it looked good at first.....until I looked at the geometry. He was not able to reproduce the models I sent, but rather kind of cheated. Yes, he didn't have a ton of time to work on the models, but he had all of Friday, and the weekend, and this morning, and was not able to reproduce any of them. There is no graph feature, and the curve by equation wasn't as powerful. No trajpar, so instead of doing things easily within the VSS, you're forced to make several curves, and they're not as easy as doing it in Pro/E. No spinal bend either.

I figured he wouldn't be able to make most of them, but I was more disappointed that instead of simply saying he couldn't quite do it, he showed us a zoomed-out view of "sorta" the geometry that I wanted, then claimed he had made the geometry and then wanted to switch to something else.....until I stopped him and showed that he had not actually made the geometry. I'm sure vendors like that HATE me, but I wouldn't be doing my job if I didn't make them do the hard stuff.

From what I see, SW has closed the gap.....not not there yet. Maybe for many, or even most, people, these tools never get used by them and they don't care. I DO use them as part of my job (Industrial Design), and I DO care. I'd have to say I plan on becoming an expert in SW also, but for new designs, I'd still recommend Pro/E for it's power.

Think of this analogy: How often do you need to use the emergency Room at the hospital.....but aren't you glad it's always there? ![]()

But hey, they brought lunch for us! ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I see too much of the "good enough" mentality in our young new-hires that I don't need them learning it from software people.

Even in everyday efforts, I find SW to lack a great deal. It's just clumsy! And I say this knowing Creo has nothing on intuitiveness but at least it makes repetition a little easier. I feel like I work in SW with one hand tied behind my back. E.v.e.r.y.t.h.i.n.g in SW appears to have some level of user interactive penalty.

It is too big a subject to focus in on any one little thing.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Agreed. Maybe it's a generational thing. When I learned Pro/E (v15 in '96), it was WAY more difficult at first, the old Menu Manager. But I stayed late at night after class at the community college, and got all the lab time I could on Saturdays (usually about 8 hours), and then when I got my first Pro/E job at Moen, I was thrown into the deep end right away (modeling everything and anything, IM plastics, formed sheet metal, etc.), and I spent hours after work and on weekend busting @$$ to learn it. I don't see that from the guys here who look at it as a part time thing......but yet insist SW is "better", even though they're definately novice users in SW.

Hopefully, this decision is at the upper management level, above those in the building, and I think they will consider what I have to say.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Solidworks 2014 & 2015 will for sure fry your brains, with the kind of bugs in it.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

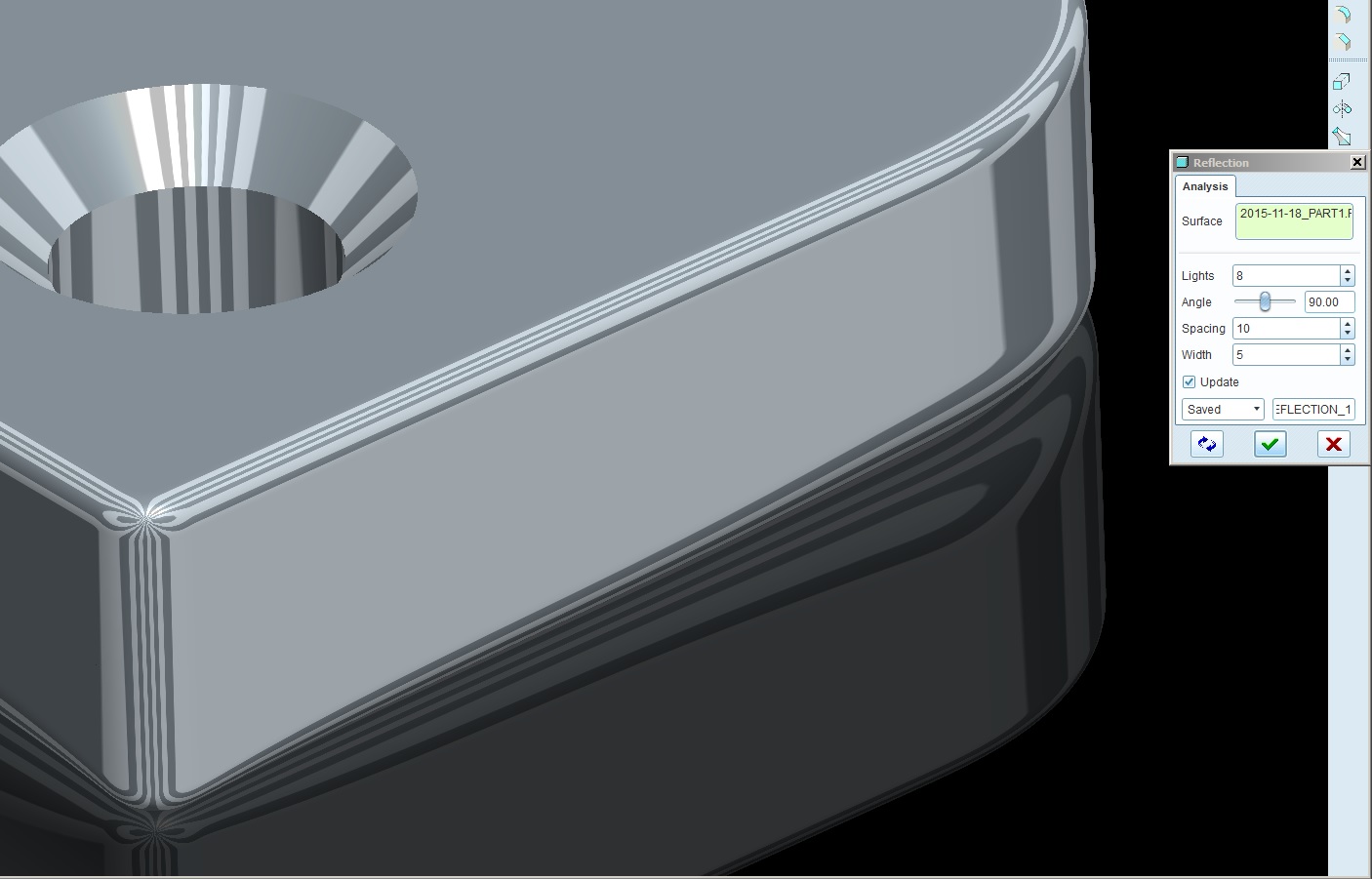

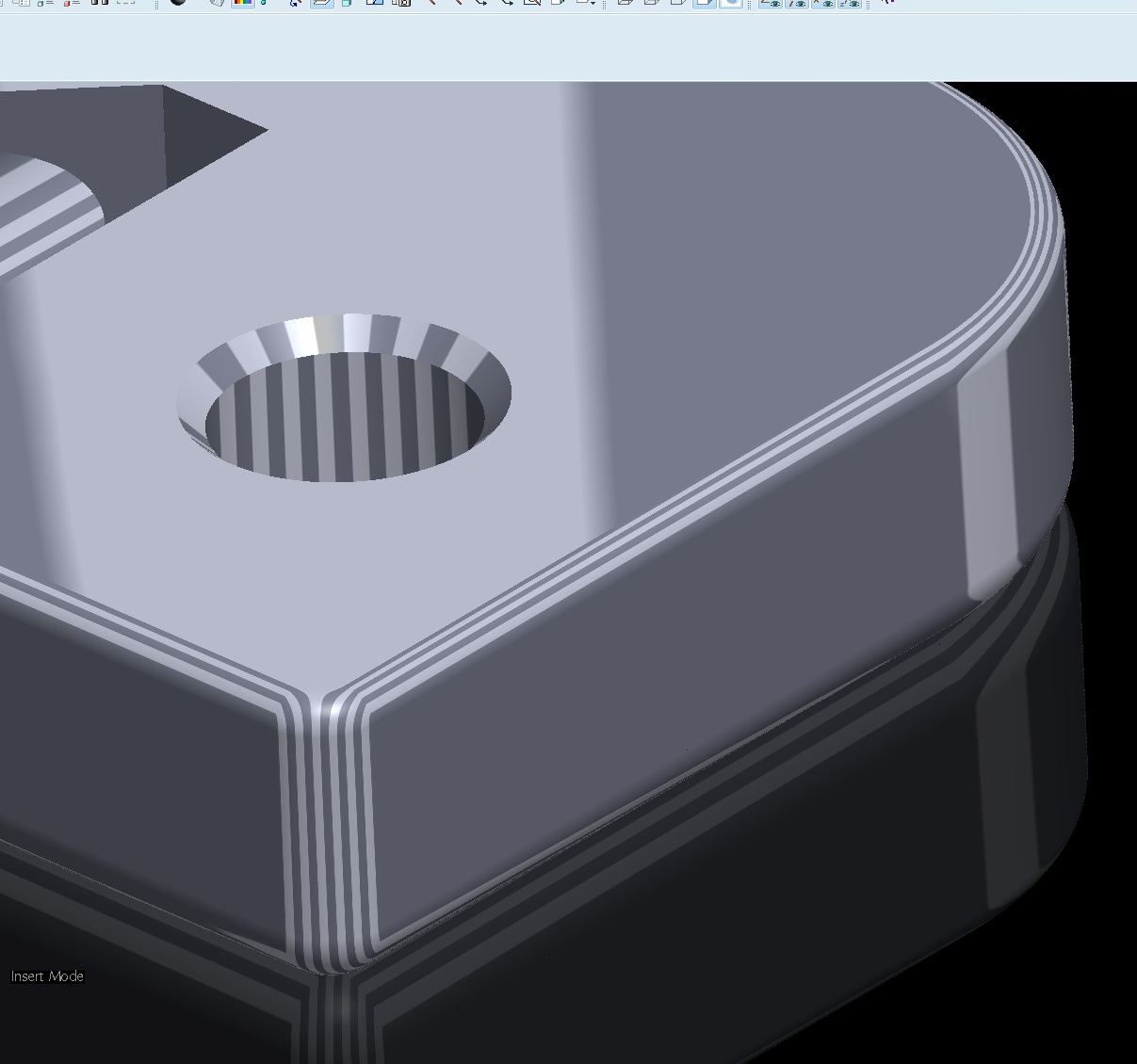

I made 2 identical parts. In Pro/E I have the ability to define different sets (series of line elements, or faces) of rounds within the same feature, and define the type of round I want. For each set, I can choose from a section that is circular, conic (with 2 editable parameters), a C2 Continuous (with 2 editable parameters), D1 X D2 Conic (with 3 editable parameters), or a D1 X D2 C2 (with 3 editable parameters). In SW I only have the option of a conic, and I didn't see a way to add the equation { (sd5 = sqrt(2) - 1 } to create the true arc, and just had to truncate that to .414.

Also, i can sketch a curve on the surface of a part, and can make the radius change to follow the curve and have my choice of section type above.

So, I did a surface analysis of these 2 parts (the reflection analysis tools having a bunch of options whereas the SW "zebra stripes" has none), and the Pro/E part had nice smooth transitions from the planar surfaces, and the SW part had abrupt contour changes everywhere.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Post images of each if you can.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Pro/E version (C2 rounds):

SW version (conic rounds):

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

One of Creo's weaknesses is fillets maybe as a price to pay to have the other features.

In the past, SW rocked on rounding everything for castings even using the single pick method.

Regeneration was very quick in SW where Creo just dogs from that moment forward.

The efficiency is not quite as robust in the newer version of SW, but still has a significant advantage to Creo.

As to the upgrades Creo put into rounds/fillets... Yes, they are nice and long overdue.

SW is lacking in innovation in this regard.

BTW: yesterday I had a corrupt SW assembly. Sent it to tech support and they agreed, it was corrupt. So sorry. Wow!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Well, at least they agreed with you! ![]()

I think we're tired of PTC maintenance, and will probably dump it all, and just buy new seats every couple years once a stable datecode is made. This has the advantage of us actually, over the years, having more seats, even though some will be out of date. I mean, after using it for 19 years, I think I have yet to get my money out of it. The "help" really isn't, and usually I end up having to fix the issues myself because they can't, don't resolve it fast enough, or it's a bug they CAN'T fix.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I'm looking forward to see if -this- actually works. Creo sure doesn't and I am not holding out hope that it ever will.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Antonius,

Am I missing something, or isn't my CREO vid showing the same functionality as the SW vid in the link?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Dean, there is a subtle but definite difference in 2D and 3D sweep cuts.

I've had PTC people try to tell me that it is the same over the years but saying doesn't make it so.

Try making something like this with a simple sweep - Video Link : 5595

Another that is related where the function is critical - Modeling a globoidal cam

Then again, my 1st attempt in SW failed miserably. You will find that "chains" of edges in SW have very abrupt changes in normals where Creo manages that much better behind the scenes. Reference edges in SW are frustrating at best where Creo is much more forgiving, if not just more consistent.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Antonius,

True...but what is different in the two videos? As far as I can tell. Mr. SW is driving a constant section along a 3D curve, which is what I did too.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The subject is pretty deep and no little post will solve it.

Pattern a 3D revolve along a 3D curve. Then sweep an equivalent surface along the same curve. You will quickly see how the leading and trailing edges of the 3D "tool" will change the results.

My favorite example is the involutes on a gear tooth where the hob making the gear has nothing but straight section elements.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

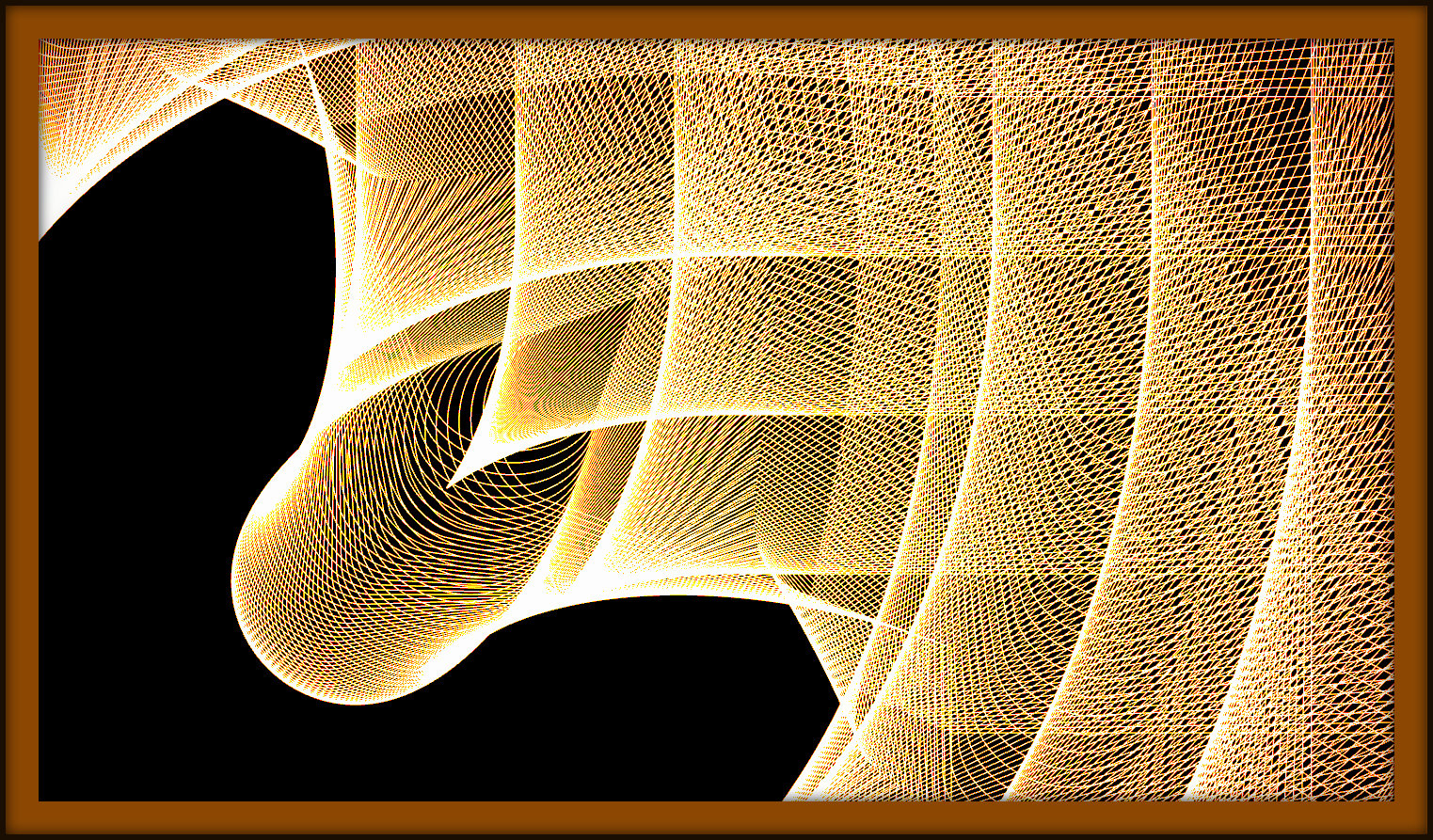

Nice picture. Takes a while to display in my browser. That reminds me of the dial-up days of the internet as it loads from the top to bottom. ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The fabled solid body sweep. It has perplexed me for years!!!

Imagine a ball end mill cutting through part and then changing angles. Nothing works to make that shape exactly in CREO. Closest I have found is the patterned revolved surface.

My current work generally is big welded assemblies so I don't use it now but about once a year, someone comes and asks, how do I make this cut??...in the land of unicorns and rainbows!!!!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The difference would be more obvious if it was a straight cut that ended in the material. With the Creo method the end of the cut would be a plane while the SW solid body cut would end with a revolve. However, from this video, I'd say the quality of the result is not as good as one would hope: SolidWorks tutorial of solid sweep - YouTube

More complicated sweeps, not handled by SW or Creo: www.cc.gatech.edu/~jarek/papers/sweep.pdf

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Here is another rather impressive capability.

Have a look under the lofted bends to see how easy it is to tweak the loft with feature parameters.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

A Blend? Who the heck uses Blends? ![]()

![]()

![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

NO NO !!! They call it a "BEND" ...not "BLEND"! Look closely ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

That is a feature I would LOVE to have! We create parts all the time that we could use this on. Every since I saw it in SW I've been pissed we don't have it in Creo. This would save tons of time for me and our fabricators!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You can expect all goodness. SW is SO much better and more intuitive than Creo. We are fighting to stay on SW. Corporate is forcing Pro-E.

The ease of 3D Sketch, you can replace a part with an assy, when creating an assy you can move items after you place them with out rolling back and losing the ability to reference those later place components.

Switch with happiness. SW in your future is reason to give thanks on turkey day.