Community Tip - Did you get called away in the middle of writing a post? Don't worry you can find your unfinished post later in the Drafts section of your profile page. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: So, they want me to learn SolidQuirks.....

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

So, they want me to learn SolidQuirks.....

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

So, they want me to learn SolidQuirks.....

Honestly, the way PTC has completely dropped the ball when it comes to getting Pro/E into colleges is the main reason. One of the reasons the SW users hers (who never actually really put forth any effort to LEARN Pro/E) are pushing for it is the lack of Engineers who can use Pro/E fresh from school. I'd rather them hire experienced Engineers, but maybe that's just me....

So, I think it will look good on MY resume, so I'm going to put effort into learning it. I will give it a fair evaluation after I've learned enough about it's capabilities, though I will say it will probably be very much like friends who are very experienced users in both and in general are saying. We'll see. There are some things I like about SW from what I saw already. I'm curious about the GUI's all the i-phone kiddies seem to love......

And, from seeing their work, I'm sure I'll be more fluent in SW than they ever became in Pro/E.....and I'm also sure I'll even be better in SW than any of them. Only one of them even remotely impresses me in SW.

So, my questions to those who use both is:

1. What should I expect?

2. What are the shortcuts/tricks?

3. What is the easiest/best approach to learn it quickly and fluently?

4. Using surfacing and the advanced features like I do, what are the comparable features and building methods in SW?

Anything else you think I might want to know.

Grazie!

Stay tuned dear friends! ![]()

Solved! Go to Solution.

- Labels:

-

Surfacing

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

If it was as powerful as the creo I'm using, I'd consider it. From what I'm seeing, it isn't, and I NEED those surfacing tools SW simply doesn't have.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I think Donald forgot the appropriate emoticon...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

LOL....

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You can always drag a component to the end of the tree so that anything that it could reference will be available when it is redefined. Creo will automatically move all dependents also, to prevent moving the component after an item that depends on it.

Maybe SW does it automatically, but it's not impossible in Creo.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

SW lets you move parts anywhere in the assembly tree. It has little pointers to dependencies. But there is no chronological order to it in the tree.

In my world, SW still looks a lot like Creo... that is to say, Creo looks a lot like SW.

Creo is definitely more refined. What SW has is a few extra things, and a whole lot of missing things. Frank found one of them with the sudden reversal of the spline above. The fact that planes cannot be recognized as edges in 2D is more annoying than you think.

However, exactly like Creo, SW doesn't always work intuitively. Sometimes the power behind a command is seriously buried in, you guessed it, yet another tab.

One I still haven't figured out is how manage a constant distance along a spline. There is some funny math going on with splines. If you create a spiral along a spline, the pitch changes depending on the curvature of the spline.

But in the end, I click twice as much in SW than I do in Creo. No wonder SW users are married to their shortcut keys. I've run Pro|E-Creo for 20 years with absolutely minimal mapkeys... and that is normally only on the fly since I have 0 (zero!) mapkeys active in my everyday CAD config.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

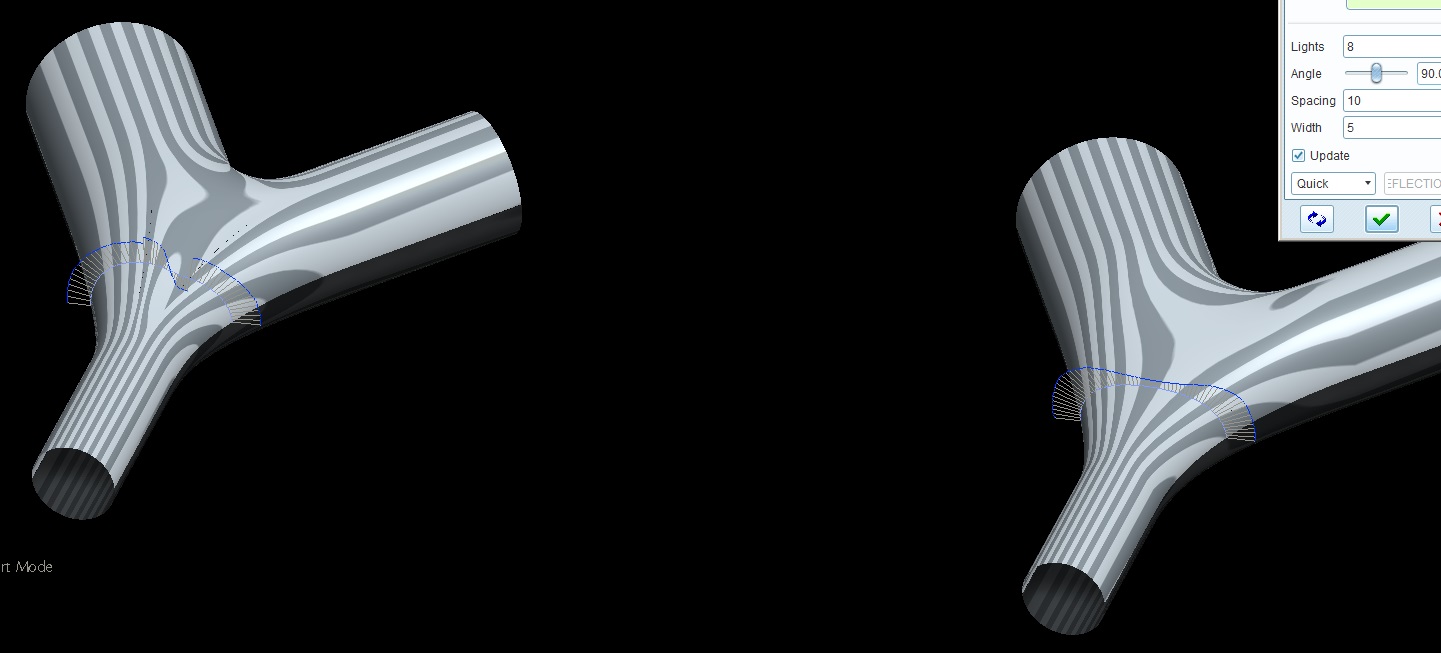

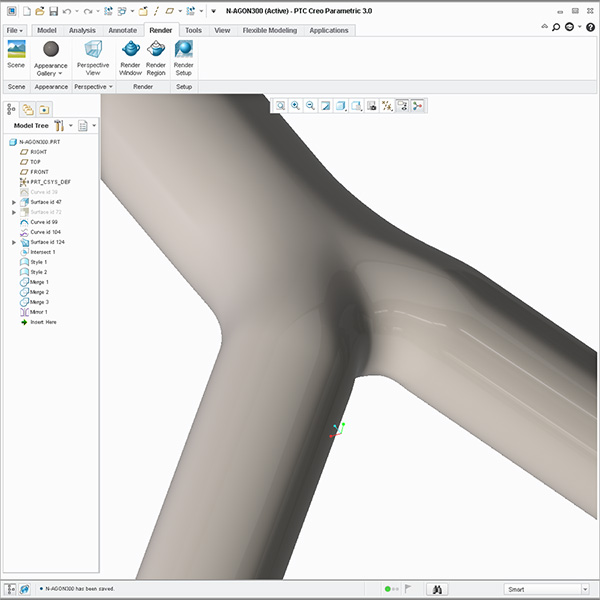

I did a blend in my ancient version of creo, and asked the local guy to recreate the models. On several of them, he got somewhat close....ish, but that's not good enough for me. Some were way off. I can honsetly say he was not able to reproduce a single model the way I had it, and needed it. Here's an example of part where I joined 3 different diameter tubes at different angles. In creo, we have an "n-sided Patch", which, while the interface is a little cumbersome when setting up the C2 edge constraints, actually did a great job, in 1 feature. Nice smooth patch. In SW, it appears he had to do a bunch of patches (more features, more complexity, more time spent, more fragile), and still couldn't get the smoothness, and even had a pretty bad curvature reversal.....NOT something you want in a mold. The SW quilt is on the left, the creo part on the right ("zebra" and section curve analysis).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Here's another interesting concept... virtual parts...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I do that above shape all with four part boundaries and G2 continuity in our one week creo surfacing class BTW. ill dig it up. Some of the folks on this forum probably did this model in that class. Solidworks chokes on models like this with similar workflow because that SW 3d curve tool is so finicky. Ill post a salad works version the next time I teach a solidworks surfacing class.

Bart Brejcha designengine.com

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I see a funny lump in it on the right. Looks like a reflection analysis wouldn't like that bulge.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hmm. Virtual Components. That one rises a bunch of geeky thoughts.

It might be able to solve a lot of problems related to manufacturing and inheritance models like this one: Not happy with model change work flow

It might be great in a tons of other situations where the design part keeps changing and many of the downstream assemblies and parts are already defined.

It just might be able to take care of all the unnecessary fake skeleton models, mirrored parts, dummy parts for the purpose of building a repeat region, etc. and clear the clutter from Workspace/Workdir.

The manufacturing portion of models and drawings don't work well with data management right now in a sense of data reuse. This concept could help greatly.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Antonius Dirriwachter wrote:

Here's another interesting concept... virtual parts...

The problem with most of the Top Down Design implementations in SW is that they are very assembly-centric. That means only one person can work on it at a time. With virtual components, everything exists inside the one assy file, so no one else can work on anything.

In Creo, using skeleton modeling and copy/publish geom features, even if I'm using the standard, assy specific copy geom feature, I can hand off parts to other folks and still work in the assy myself. A very powerful tool that we've used to great effect here. I've not found anything close in SW yet.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Of course, Doug, this is not a standard way of working but for inseparable assemblies such as OEM parts that logically have multiple pieces. For instance, a linear motion belt drive can have a couple dozen pieces from a manufacturer's download. If you make it a single part in Creo, it has one hatch style. If you have a virtual assembly in Creo, in theory you would also be able to map multiple hatch patterns to the single component.

This whole issue was a huge stumbling block for Siemens NX. If you have a PDM that drives all BOMs from CAD, how do you deal with OEM-part-1 and it's fiddly bits as assembled. Meaning... if I have a NNNNN convention on file names, how do I make part 1, part 2, and part 3 of NNNNN without it showing up in automated BOMs as 3 items and an assembly?

Also: Would this aid in composites in Creo?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Antonius Dirriwachter wrote:

Of course, Doug, this is not a standard way of working but for inseparable assemblies such as OEM parts that logically have multiple pieces. ...

Agreed, this would work well for OEM assemblies, in fact it would be a fantastic solution.

I was reacting to the contents of the link you posted where virtual components are specifically promoted as a TDD tool:

"Virtual components are especially useful in top-down design. During the conceptual design process, when you frequently experiment with and make changes to the assembly structure and components, using virtual components has several advantages over the bottom-up design method ..."

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

what's up Bart, its been a while man!

anyway, I have used both, and they both have pros and cons, I am not a super user like some of you guys, but stand behind pro-e, I like SW but I prefer pro-e, I don't understand whats the hate about SW guys have towards pro-e but its kind of silly.

when I learned SW after about 10 years on pro-e I did what most probably do and I tried running SW like I would pro-e and SW choked and choked and choked.it does not like large assemblies with flat model trees, you got to make a bunch of sub assemblies to keep it happy. even though SW guys love the whole picking mates from all over the model tree order, I think that's what makes it choke with the larger assemblies if you start thinking about how it has to calculate all its mates scattered all over the model tree instead or organized like pro-e.

I do like the fact u can pick faces and get the mates menu to pop up same with the constraints menu in the sketcher, but other areas are just pretty lame. as mentioned before the flexibility to create datum planes and axis etc etc etc is very sorry to say the least.

3d sketching is cool but nothing to write home about.

weldment module is pretty cool, but sheetmetal module is a little clunky, last I used it you couldn't do a swept flange in sheetmetal, something really simple to do in pro/sheetmetal.

SW guys are non stop about the extra clicks u got to do in pro-e like its the end of the world, YES SW is more intuitive, no doubt about that, but its almost like a pilot saying he rather fly a Cessna because a F16 has too many buttons or a racecar driver saying a YUGO is more intuitive than a Formula1 racecar.

anyway, i think if SW guys gave pro-e a honest try, instead of just gripping how much better SW is or trying to run pro-e like its SW, if they got to that magical point when u understand just enough about pro-e to where u could sort of stumble your way thru the other modules, maybe they would have a better appreciation of it, and at the bare minimum its not a bad thing to have on your resume but my experience is some SW guys almost rather do a career change before learning pro-e...

Carlos

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

the version of SW I was on(I think like 2012) also didn't have a circular reference file like we have in pro, when u get what SW considers a circular reference, its a nightmare to fix.

beware as I think someone already mentioned for NOT FULLY DEFINED sketches.

create lots and lots of subassemblies so it doesn't choke if u are working with large assemblies. the SW reps will claim it can handle these gigantic assemblies but that is ONLY if every single model is done exactly how they want it, and only if u have nonfully defined mates so it has less to calculate, and that's only if ............. point is if u are starting a giant assembly from scratch and modeling all the components from scratch, that would be the only time to actually set it up correctly and maybe get huge assemblies to work, the rest of us who actually have to work with legacy data, and there is no chance in hell our managers will approve time to go back and remodel every part correctly exactly how SW wants you to model it, we'll be screwed dealing with SW choking on huge assemblies.

I think its a cool software, and definitely has its place, but just like anything else it has its limits.

Carlos

- « Previous

- Next »