Community Tip - You can subscribe to a forum, label or individual post and receive email notifications when someone posts a new topic or reply. Learn more! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Surface to Surface round issue

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Surface to Surface round issue

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Surface to Surface round issue

I'm creating a surface to surface round feature from one surface on a flat, to the other surface being a cylinder (diameter). The cylinder surface shows up as two half, and the end of each half is right next to the surface i'm selecting. If I do a small radius and it doesn't touch were the half's connect, i'm fine. When I make the radius what it needs to be, and it goes over that connection line, I get an error. There are 3 of these flats, 120 degrees apart. The other two work out fine, because they are not next to were the cylinder connects. Ids there anyway to make the cylinder as one, or is there a option in the radius creation that would help me.

Solved! Go to Solution.

- Labels:

-

General

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

also try to reorder that small vertical cylindrical feature after the round. may be after all the rounds, this cylinder may be buried.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

a snapshot would help

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

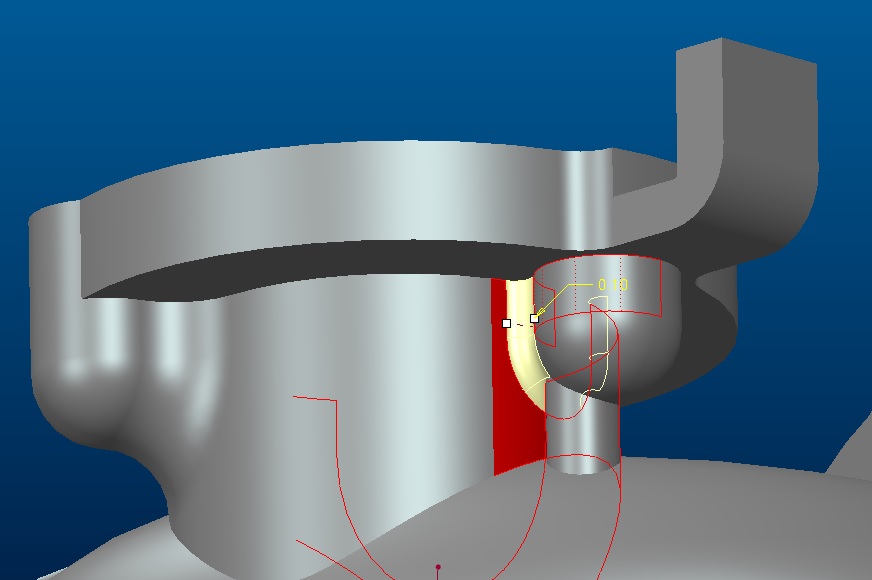

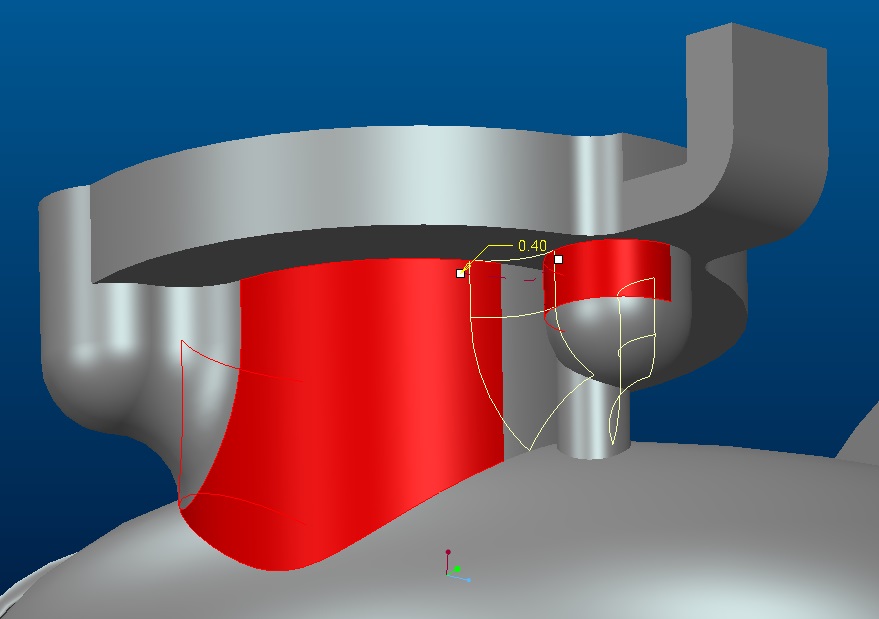

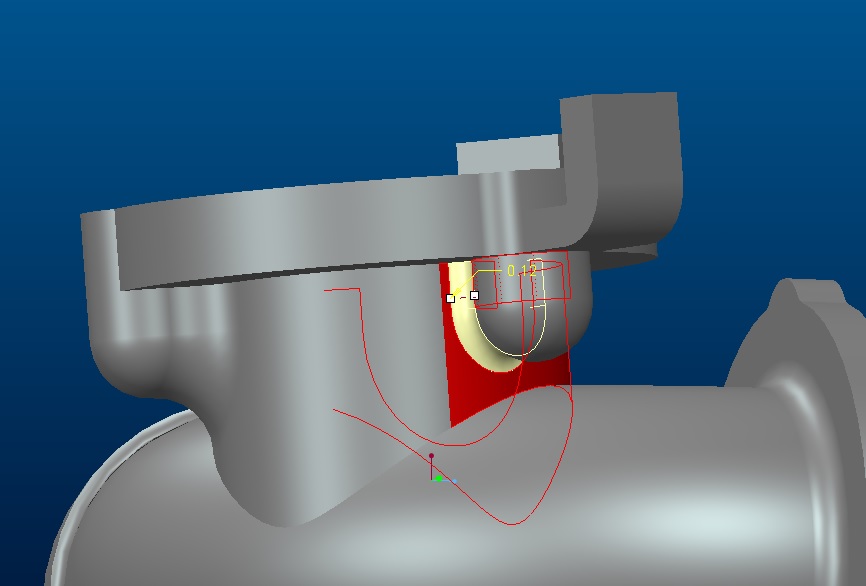

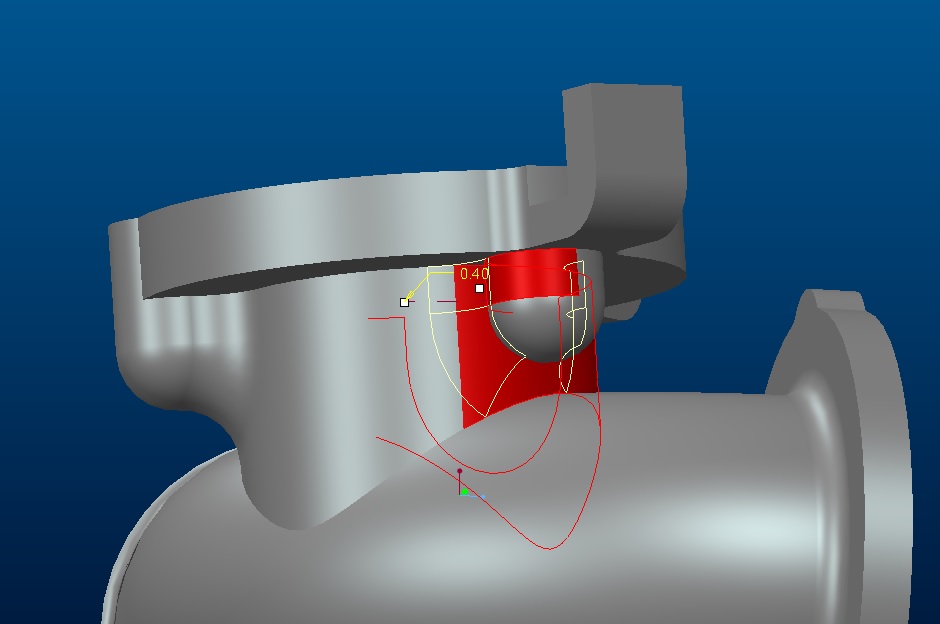

Attached are two images, I need the .400 radius. You can see the cylinder line and were it crosses over in image two.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi John,

My guess is the failure is being caused by radius of the round being too large. Try using transitions and also maybe try changing the accuracy.

Amit

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Is it possible to attach the model for us to check?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

also try to reorder that small vertical cylindrical feature after the round. may be after all the rounds, this cylinder may be buried.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I removed the small cylinder to take that out of the mix of being the problem. There are two other bosses on this part that accept the .400 radius, you can see one of them to the left in the images. There reason why it works on the other two bosses, is because it happens to be on the full big cylinder surface and not where it splits in two.

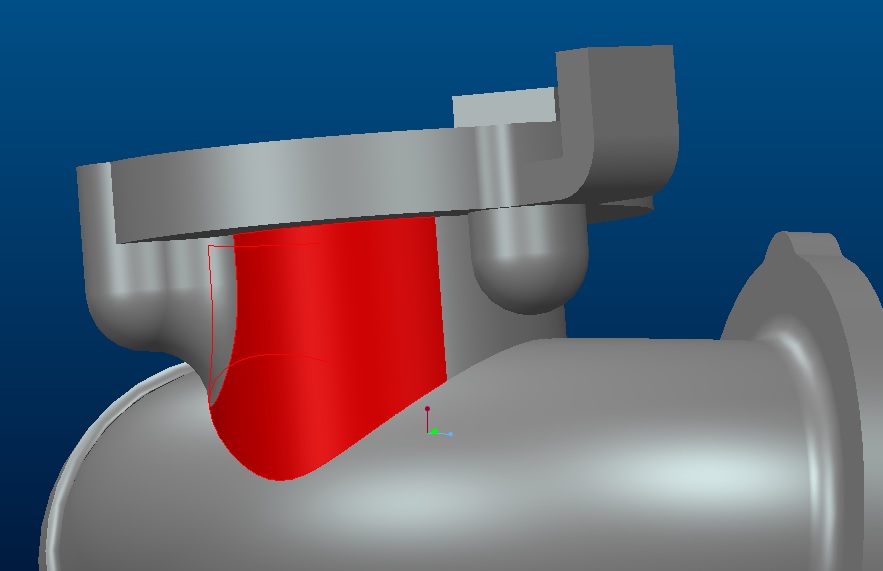

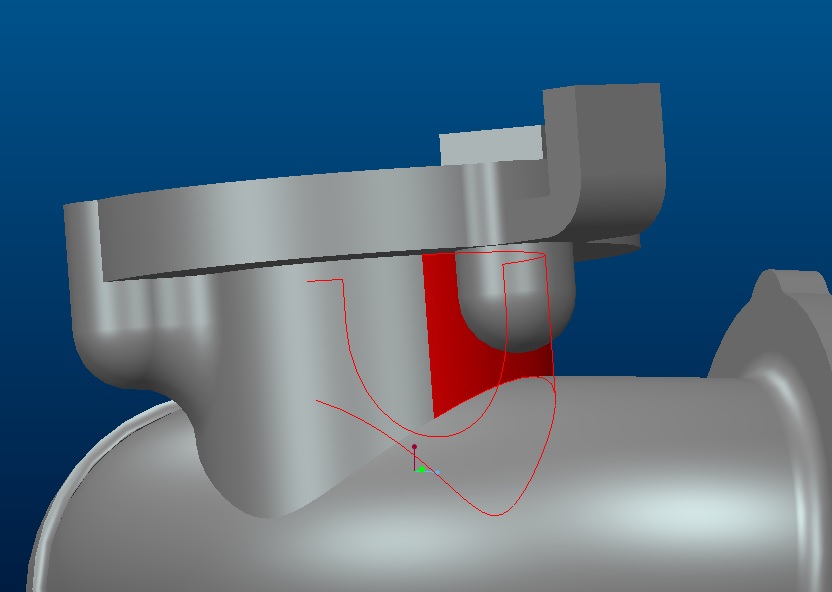

I'm attaching 4 pics to this post. The 1st and 2nd image shows that when selecting the big diameter, it selects as two half, not one full diameter. The 3rd image shows the smaller radius working, because it's not going over the border of the one half of the big diameter. The 4th image shows it failing, because the radius is to big to stay on the selected half of the diameter, it's going to the other half (surface) that is not selected.

The problem is definitely that the big diameter splits in two when selecting. Which is normal for models in Creo, but wondering if there is a work around when either creating the radius, or being able to select that cylinder with one full selection.

Thanks in advance for the help.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It is difficult to provide an exact solution without the model. But try to select the other half surface of the cylinder from you 4th picture. or try to select the edge of the boss only instead surface to surface.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The other two locations have room for the round. In a real part, rolling a ball bearing of that radius would force the bearing off the vertical large diameter so that surface isn't involved anymore. Just run that boss all the way to the elbow and put the radius on each side and then one across the boss and the elbow.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

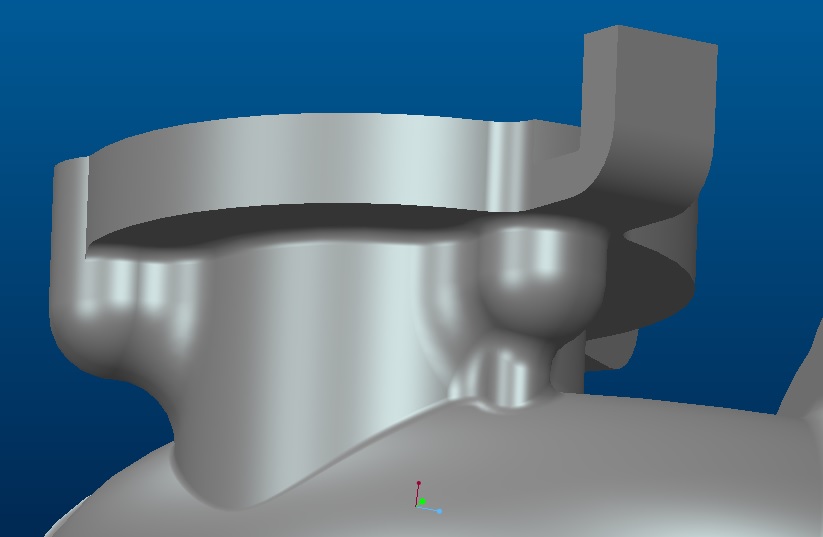

I got it to work using a suggestion from one of the replies on this page. I reorder that small vertical cylindrical feature after I placed the round, and then put an additional round on the small cylinder after it was created. I originally tried that, but did not get it work before, now it's all good. See in the attached photo. Thanks for everyone's suggestions and help.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Glad it worked.