Community Tip - Did you get called away in the middle of writing a post? Don't worry you can find your unfinished post later in the Drafts section of your profile page. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Thicken for style surfaces

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Thicken for style surfaces

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thicken for style surfaces

I don´t know if someone else have this problem. Working with ISDX or style feature sometimes including with 4 sided surface i have problem tos make

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Labels:

-

Surfacing

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello Camilo

Yes of course, you can use a offset feature for sheetmetal part (Insert > Sheetmetal Wall > Unattached > Offset...).

The first offset value set "0" and then set thicken for your surface.

Vladimir

Vladimir Palffy

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks Vladimir,

I tried that but a new problem appear in the message box that said: " Radius of curvature of bend or form must be > thickness.", i tried with 0.2mm didn´t work and that i need is 4mm, probally i have a complex geometry here so what i need to correct?.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Camillo,

this is hard to say without seeing the geometry.

Causes could be too large curvature (=too small radius) or things like degenerated points (any three sided surfs?)...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Camilo,

you can use Offset analysis feature to detection your required surface: Analysis > Geometry > Offset - select surface for offset / set offset distance.

Vladimir

Vladimir Palffy

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

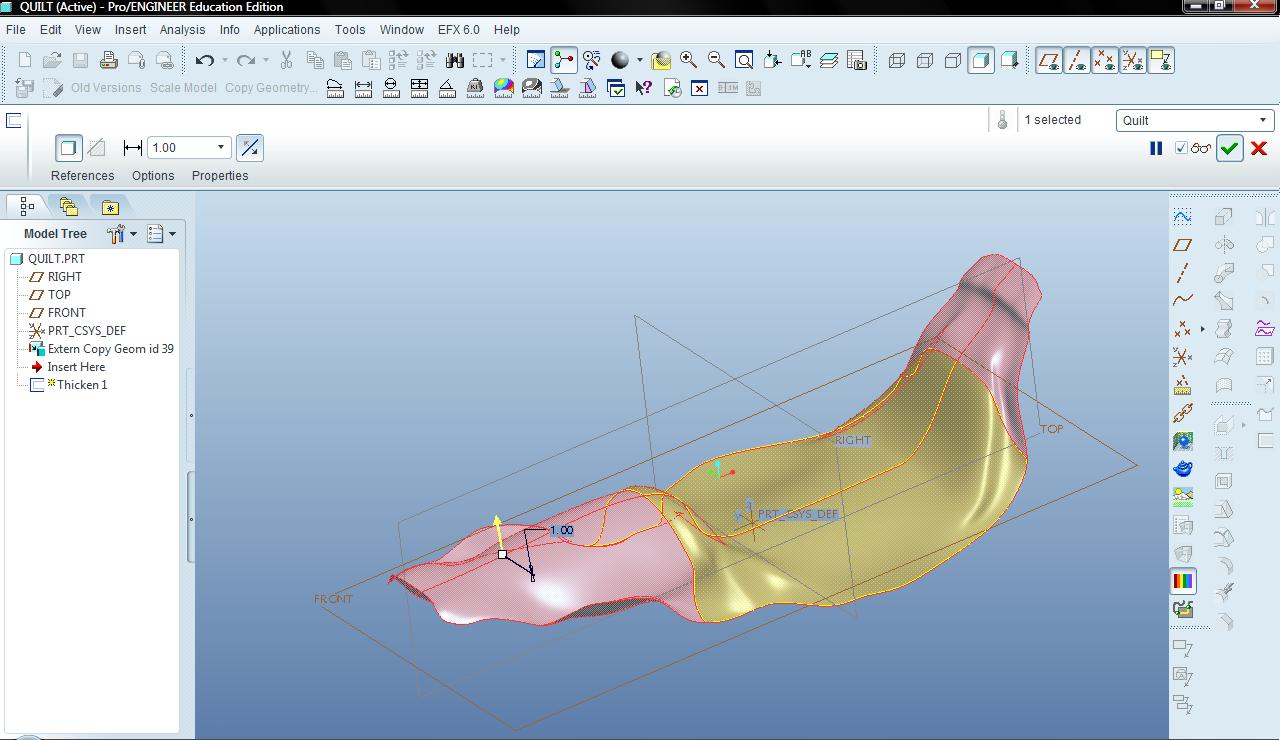

Look my geometry trying to make a thicken, i need 4mm and only the central surface let me this. In the quilt the 3 surfaces are 4 sided.

With the offset analysis I could see problems at the ends. The problem is that i can´t change the form too much.

Thanks

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

If you can't change the geometry, the only way out would be to create a solid by adding more surfaces, that is making a enclosed volume by closing your quilt will additional surfaces, merging them and turning to solid. For example your current quilt will be the top surface, then manually create surfaces on bottom, front, sides by creating a closed volume. Then Merge all the Quilts--and Solidify.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Albatros i do it and works like sollid, but that give me a variable thicken form 1mm to 4mm on some areas because the surfaces have many no perpendicular direction to the views.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello Camilo

If you need a variable thickness, you have to offset (create) quilts as necessary and then use a procedure written by Albatros ![]()

Note: if you use Offset feature you can use Automatic Fit or Controlled Fit Option where you can Create side surface.

Vladimir

Vladimir Palffy

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello,

In case offseting the surfaces do not work, I will recommend to manually create the curves network. You can intersect the quilt with a plane and that will

give you a curve. Save this curve as a sketch and use it later on as a reference to re-create new curves for your closing quilts. This way you know that this curve has the same profile as your quilt

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

No i need a constant thicken of 4mm, with automatic fit only works with the middle surface, networking the geometry leave me a boudaries surfaces with the same problem.

Thanks for helping in this problem.