Community Tip - If community subscription notifications are filling up your inbox you can set up a daily digest and get all your notifications in a single email. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Trouble with matching tilted customer sections

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Trouble with matching tilted customer sections

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Trouble with matching tilted customer sections

I need to build a preform type model based off a customer model. I want the new model to be totally independent of the customer model.

The customer model has a number of tilted cross sections that I need to match.

From a previous Creo forum post I am trying a method to place my tilted datums that I will place sketches to match the cross sections.

The method that I am using is to 1st place a tilted coordinate system and then place the datum plane on the coordinate system.

Before I do this I generated a temporary datum plane off 3 points on the tilted cross section. I place a central point on a sketch driven off the temporary datum plane. This gives me a XYZ location of the coordinate system which I build.

Next comes the problem; I need to tilt the coordinate system to the same inclination of the temporary datum plane.

Laying this in my top view I can measure a angle that would be rotated around my Z angle in the coordinate system. (I make a top view sketch and project a line down to the top datum and measure this angle. SEE BELOW)

This gives me my Z axis rotation value.

Next I take the green line shown circled in the picture above and extrude this in the Z direction.

If you look at this normal to the temporary plane you can see that there is a small amount of rotation from the vertically extruded line.

I capture this value and it becomes my X rotation.

My coordinate system has the following rotation values.

When I place my datum plane to this I go back in to analyse the resulting rotation value between the temporary and placed datum. I want the value to be 0 just like the distance, but here is what I get.

I really don't know how to evaluate the above .216 value. I can see that I have a small rotation error in my model, but I don't know what direction this error is in.

I did not rotate anything in the Y axis, but I really couldn't see how to even determine this value. I was hoping that this rotation wasn't even necessary.

Would anyone have an idea of how I could lock on to the XYZ rotations to match the customer sections?

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

Solved! Go to Solution.

- Labels:

-

General

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

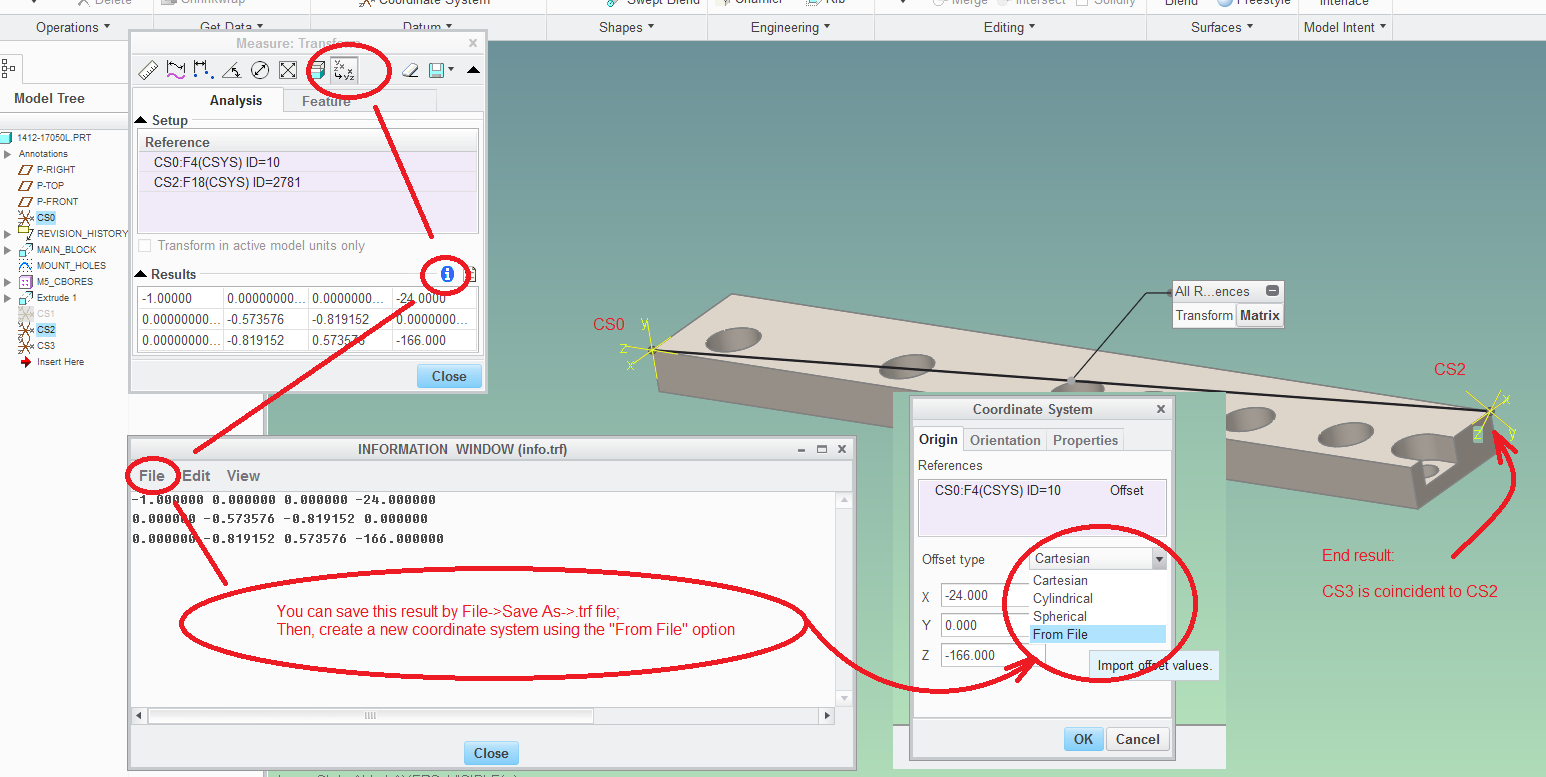

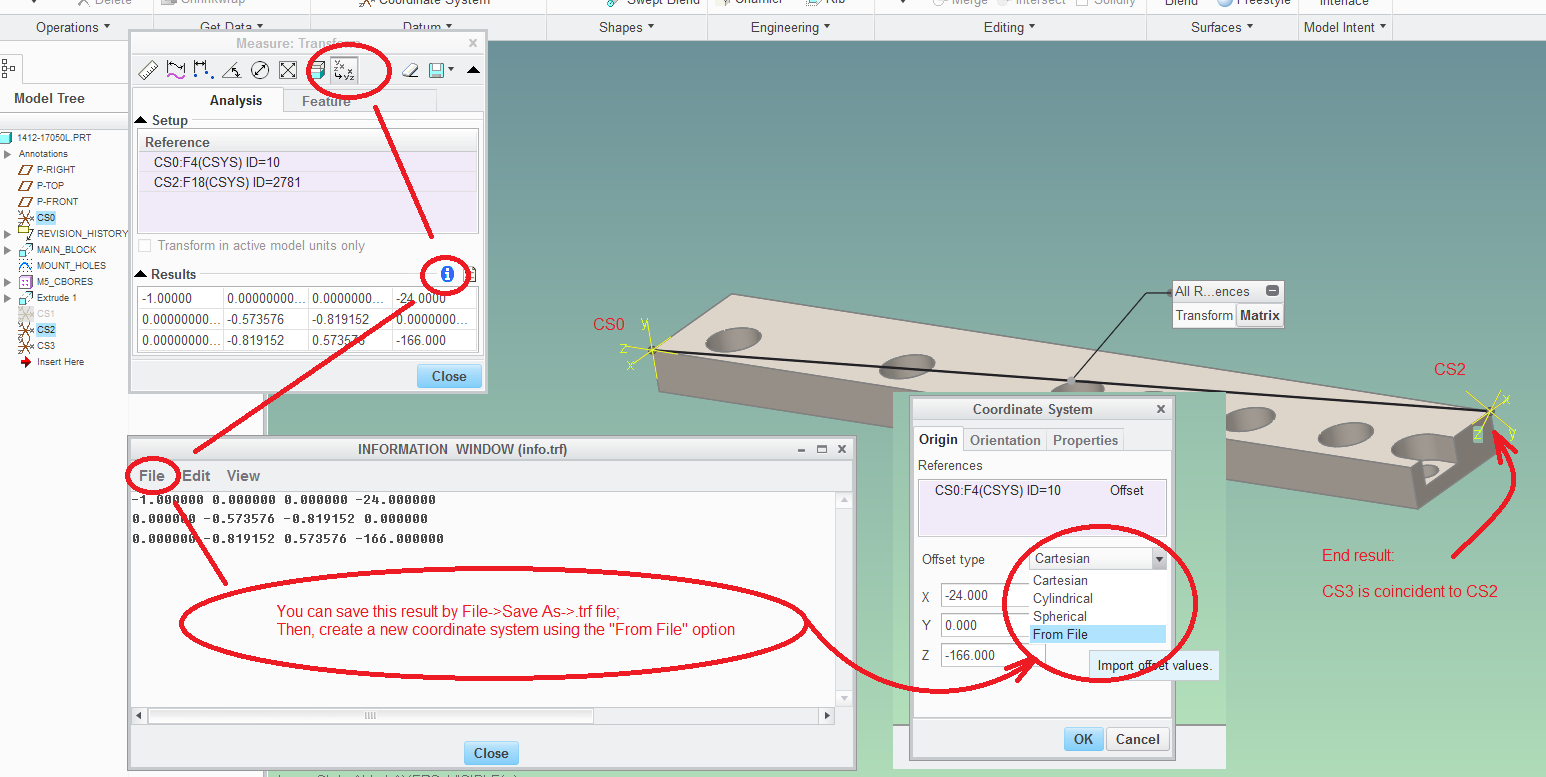

In Creo 2.0, you can use the measure tool to get the 3x4 transformation matrix from one coordinate system to another. You can then capture that information to a .trf file, and then use that file to specify how a coordinate system is positioned/oriented with regards to a reference coordinate system:

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

A little update.

Above I noted that I didn't apply any rotation in the Y axis because I didn't know what to even rotate about.

The sections are all ribs. I took the central thin section of the rib and placed a X direction line parallel to the thin section.

I measured the difference between the X direction line and my top plane and I used this value as my Y rotation.

This tightened my difference to perhaps .1 degrees but I'm still not exact. I'm not sure that I can get exact when the tilt is applied to all directions.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

When you place the coordinate system, pick the datum plane first to set the orientation, then pick the datum point to set the location. There should be a final pick to finalize the orientation.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Are you translating and rotating the coordinate system? I have found that either I get confused or pro/e gets confused when I translate and rotate. I usually translate with one coordinate system and then rotate with another one tied to my translated coordinate sys.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Stephen,

You may be speaking about positioning the main CSYS or possibly all the downstream CSYS. In either respect I would agree with you about the confusion.

I do use a main sub coordinate system to rotate my solids, but in this case I am talking about numerous coordinate systems to develop the datum positioning.

Below you can see the end result of what I am needing. The datums were developed from the customer model but now they are all independent (albeit with a small amount of error).

I might be able to have exact datum placement if I were to copy geom a number to the faces from my customer geometry and do planes to 3 vertices, but the below method is much cleaner. Just wish there were a way to get exact results.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Can you not take the transformation matrix of a coordinate system using references and duplicate it in a new coordinate system?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Antonius,

If I understand you correctly the problem would be that it would reference the customer model and I need to break the dependence.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I was trying to find the transform matrix of a coordinate system. I couldn't get IGES to output the alternate CS.

I know that with some "magic", you can capture the transformation matrix of a CS.

Once you create it using existing geometry, you output that data and apply it to a new CS.

That way it is independent based on the master.

What I am not finding is this information regarding the CS matrix directly. However, you can change the view to the referenced CS and you can capture the view transformation matrix based on world CS. Again, haven't done it yet, but one of these methods of capturing the information should get you there for an exact copy if not albeit single precision or less.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

In Creo 2.0, you can use the measure tool to get the 3x4 transformation matrix from one coordinate system to another. You can then capture that information to a .trf file, and then use that file to specify how a coordinate system is positioned/oriented with regards to a reference coordinate system:

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I knew I'd seen that before ![]()

Thanks Paul.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Paul

Excuse me for being turned around.

From what I am seeing you are doing is capturing the data from an existing CSYS to use in another assembly part to generate another CSYS.

In my case I don't have any existing CSYS from my customer model. I have built datum planes inscribed to 3 vertices on each of my needed sections.

Unless I could place a CSYS to 3 vertices in the customer model I can't build CSYS to determine my sections exact locations.

I have been placing datum planes to my sections because this appears to be the only way of capturing it's exact location. Unfortunately this doesn't place straight on the section. There is an unpredicted rotation. My next step is to build a sketch on the 3 vertices datum plane. With this sketch I am guessing at the rotation inclination and center position all I know is that I can then place my coordinate systems extremely close to being on the datum plane which is placed on the section. I can then measure my section datum plane to the default planes to tilt my Csys.

An awful lot of work for not getting exact results.

I do wish I could place my CSYS directly to my customer geometry sections; then it appears I would be able to get an exact capture.

Any chance you could exact capture a datum's location and inclination?

Thanks for bearing with me.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Paul - I was just showing how you can create an independent coordinate system that is exactly coincident (to within the machine's precision) to some coordinate system that was dependent on geometric references.

I think your problem remains as to what references from your customer model to pick...

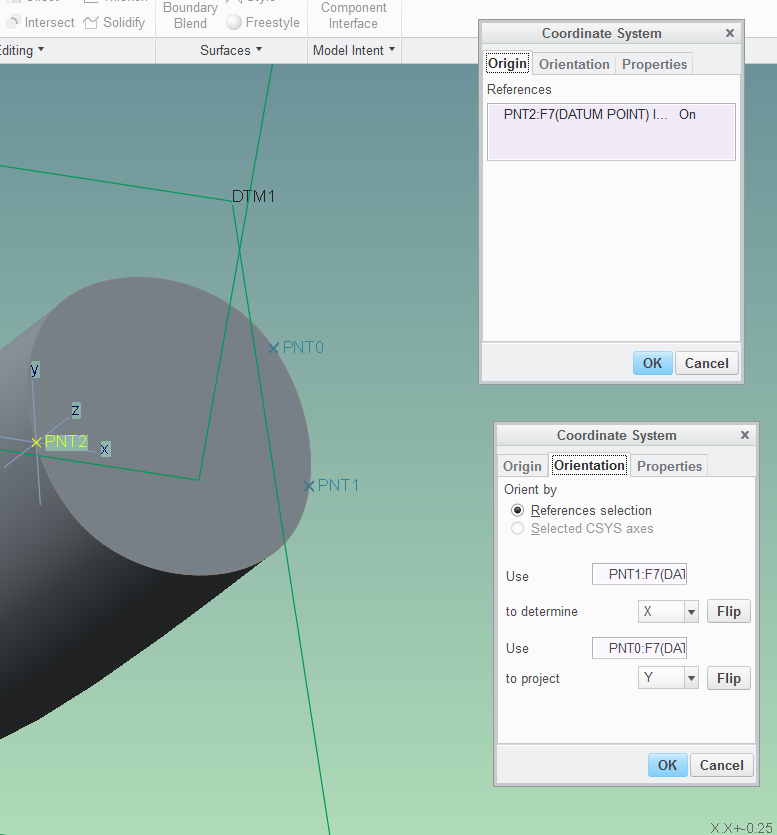

Anyway, you mention that if you could build a csys from 3 vertices in the customer's model... - well you can do that:

You can define a coordinate system from 3 points, vertices, etc... In the example above:

PNT2 determines the coordinate system's origin, PNT1 is used to direct its x-axis, and PNT0 is used to determine its y-axis.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Paul,

This certainly helps. Creo's interface makes it difficult to know that placing a 3 vertice coordinate system is even possible.

Once I did this it was fairly simple to do as you suggested from above in capturing the position and inclination of the CSS.

This saves steps and is more accurate than what I had been trying.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Look at the filter items available when you go to place the feature. This will generally be a clue as to what is acceptable, though it may also give options that will replace current selections rather than be available to add to them.

For example. picking the section plane first gives two placement handles, so you know those are required to be dealt with. Even though vertex is still an option in the filter, it is to indicate you can replace the initial plane selection with a vertex and the resulting chain of choices that offers.

There may be dozens or hundreds of paths and no good way to represent them in a compact method that would allow you to pick one that matches your mental model of how it works.

Given that you want a csys to be oriented to a plane, that would indicate that the first choice should be a plane. If you want to go through vertices - then pick vertices first. That sort of thing.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks for the idea about filters.

Perhaps there are other times I give up too quickly on possible interactions because there aren't apparent options available.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Another option is to create an Independent Geometry feature, then collapse the Coord Sys datum feature into it, so the CSYS becomes included in the Independent Geom feature and that way independent from the model.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

There's one more technique I've used when doing piping assemblies. You create the csys using external references, then redefine in the subassembly and pick the default csys (assuming you have one) in the model. The external references are removed and the csys dimensions are filled in correctly. I think in your case you'd have to create a couple of dummy assemblies that you could delete when done. I've attached a Powerpoint showing the steps. It sounds harder than it is, once you've been through it. Any way, it's one more weapon in the arsenal.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

YES, I've done it this way before. I couldn't remember the detail though. You are right, it sounds complicated but it's really simple and quick.