- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Tutorial: Sheet Metal Conversion - two example...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Tutorial: Sheet Metal Conversion - two examples

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Tutorial: Sheet Metal Conversion - two examples

In this tutorial, you can learn How to use Sheet Metal Conversion modelling technique in ProE or with same logic in Creo Parametric.

This video was created based on question from a comment under my video on YouTube channel. Fell free to contact me or leave a comment, or idea for another Creo tutorial.

Vladimir Palffy - www.4kside.com

Tags: #proe #creo #creotutorial #tutorial #4kside #palffy #vpalffy #vladimirpalffy

Vladimir Palffy

- Labels:

-

General

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

the second method is absolutly fantastic. All in one feater... it´s around 6-8 features less than l would use.

Applaud for you...

Thanks for great tip

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Good stuff, thanks for sharing it.

A method I've used that's similar to the second is to shell the solid before the conversion. If you shell to the length of the return flanges you want, you can get consistent flange length on a more complex part where a simple extrude won't give you what you want.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

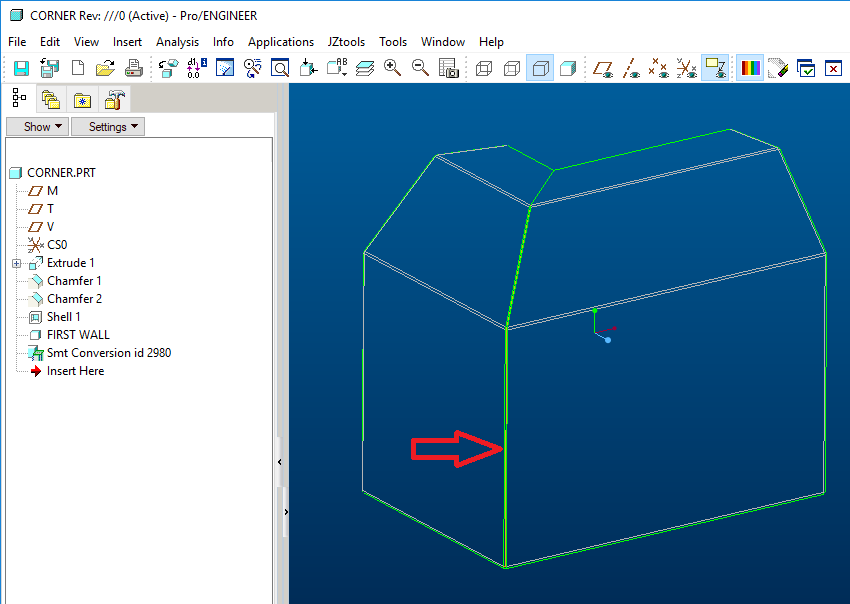

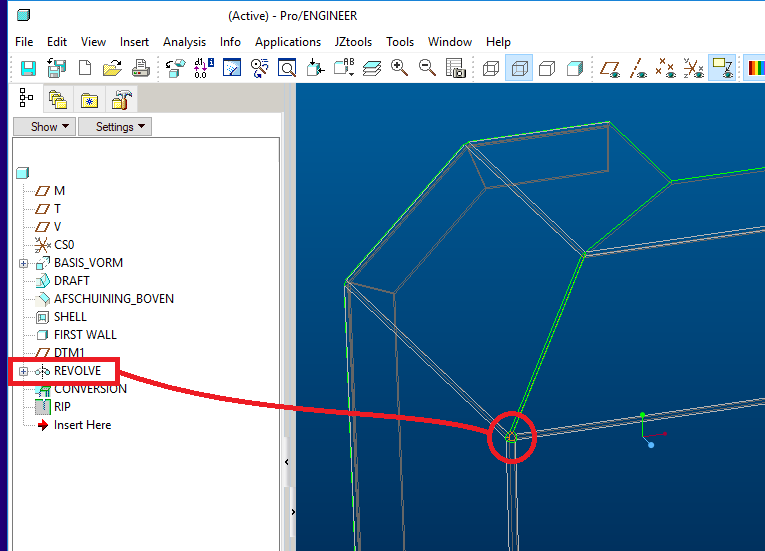

I have a challenge for you guys 🙂

We use the "start with solid, then convert to sheetmetal" method a lot, but this part in particular is giving me headaches.

Please see the picture below. The edge the red arrow is pointing to is now defined as an Edge Rip, but I want to have a Bend at that edge. But Creo keeps throwing an error when I want to change that edge to a bend.

In my mind, it should be possible...can't get it to work.

Any ideas?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This week I am out off office, but next week I will create it 😉

Best regards Vladimir

Vladimir Palffy

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks in advance, I'm looking forward seeing your solution 🙂

P.s. The part posted is from PRO/E Wildfire 4, but we also have Creo 4.0

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I don't have time to play with it today, but here's a quick suggestion. Add a round to the solid to the edge that you want the bend and apply the edge rip to the seams above it.. Not the most elegant, but I find that sheetmetal doesn't often respond well to elegant solutions.

Frankly, my experience with sheet metal is trying several variations of things that I'm pretty sure should work but don't, not knowing why and coming up with a reasonable and useful workaround like this one to keep things moving along.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

@dgschaefer wrote:

Frankly, my experience with sheet metal is trying several variations of things that I'm pretty sure should work but don't, not knowing why and coming up with a reasonable and useful workaround like this one to keep things moving along.

Been there 🙂

I have tried to add rounds (inner and outer) to that edge, but I still can't get the conversion to work 😞

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I see that you fixed it below, but I meant add the round to the solid before it's converted to sheet metal, not before the conversion feature.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I have tried adding rounds to the solid (before the first shell, and after the first shell), but I still could not convert it (see my reply on the first page).

Adding a round to that edge also creates problems with the "bottom inner flange".

Thanks for the suggestion though!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

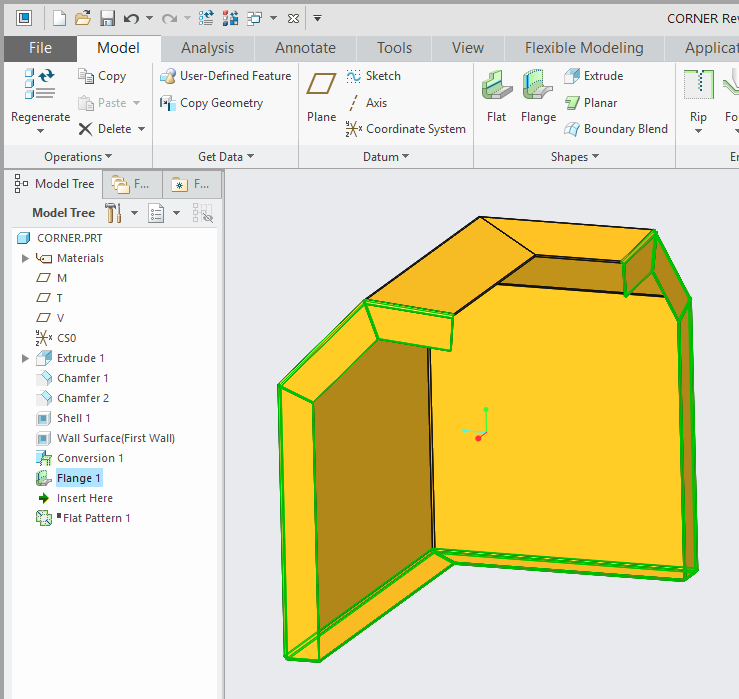

Hi,

I have tried it - and seems that it easy - try to check the video

Note: in reality The Flange features is necessary to add - because at the bottom of your original shape is necessary to create Surface RIP >> the Flange feature remove this surface automatically

Good Luck with SMT conversion 🙂

Vladimir Palffy

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks @VladimirPalffy!

It seems like having all the flanges in the conversion is a bit too much for Creo.

Without those flanges, Creo 4 can make the conversion, but PRO/E Wildfire 4.0 still fails.

So it seems like Creo 4 does have some improvements in sheetmetal.

B.t.w, it's possible to create the other flanges in one flange feature, see attached picture:

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator