Community Tip - Stay updated on what is happening on the PTC Community by subscribing to PTC Community Announcements. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Will a Pro-e user ever expand to 3D Direct CAD...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Will a Pro-e user ever expand to 3D Direct CAD, or is he stuck in a parametric mindset?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Will a Pro-e user ever expand to 3D Direct CAD, or is he stuck in a parametric mindset?

Once the parametric approach is set and fixed in many Pro-E minds, it feels like there is no other way.

You might think : fact is, 3D CAD is complex. Only the best engineers will therefore work with Pro-E.

What if I say your job doesn't have to be for PRO's only. It's often just the tool you are using that is making it complex.

PTC has announced Project Lightning. Have a look now at what 3D Direct CAD has to offer for all Pro-E users.

3D Direct CAD solution is available to you today. Within PTC it is known as CoCreate Modeling.

It is likely that your engineering processes can improve by adding 3D Direct CAD.

Can Pro-E users think out of the box? Or are they stuck in the history-tree paradigm?

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I, for one, would like to think that I could adopt and assimilate direct modeling. There are many times when I wish I could simply abandon the strict structure that I've made for myself for a "quick" change. BUT, I have to say, that when a sweeping change, fully and correctly updates the entire model and the applicable assemblies, it is most gratifying! I hope that there is room for the coexistance of both approaches for I would not want to lose one to gain the other . . .

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Echo that!! I saw the PTC demos of CoCreate at the ptcUser convention; very slick for sure! I also feel that I am open-minded enough to look at alternative methodolgy even after 15 years of designing in Pro. HOWEVER, when you know what you are doing with Parent-Child parametric design, you are creating something else in addition to geometry, namely driving logic. . . just waiting for that one little tweak that changes everything. . . just the way you wanted it to. It's more than a little perjorative to dismiss this as "being stuck". It appears that PTC is moving in the direction of marrying the two approaches. If they can do a good job of it, it could be really great stuff!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

David Butz,

Gentleman,

I requested about this on 11/30/2007 as per my product enhacement request E5991916 to PTC. In addition to this request, I also made a request about

synchronous technique similar to Unigraphics on 08/18/2008 as per my product enhacement request E6356308.I guess PTC do not like suggestion

nor bother to let me know that PTC is considering it.

Gautam Vora.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

David,

Do not mixup the Direct Edit with Dynamic Modeling concept.

You can 'drag' dynamically some geometric features, but that will eventually just update the history-tree parameters.

So you will still have a fully constrained model.

Dynamic modeling has no* relations, you can edit the geometry as is.

*Also CoCreate Modeling has the Advanced Design options to fit in some relations.

This could blend in perfectly for those who need more Dynamic, but cannot do without a few relations.

Perhaps the 80%-20% rule applies for both solutions today.

Let see how Project Lightning develops...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

3-D Direct CAD is probably a "Rhino" tool for Engineers. It is the same concept as Rhino and is invented to make things "easy". However "easy" should not be confused with "lurch" modeling, since many initial gains in the product cycle, will get lost later one during the product development cycle.

On the other hand, the Direct Modeling lacks the advanced features of the current parametric approach such Surfacing and ISDX

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello Maurice,

The first thing your question brings to my mind is to turn it back around and ask you the opposite question. Will the CoCreate users ever expand to Parametric Modeling, or are they stuck in the explicit mindset?

I say this for many reasons. Let me try and explain myself while trying not to offend anyone. Here is my background so you can see where I am coming from.

I started using CAD Tools in 2001. I have used: Pro/E, Catia, Solidworks, Inventor, Ideas and CoCreate. Obviously I am not that great at some of them. I have the most experience with Pro/E. I am currently the MCAD support person here. We started out many years ago as a Pro/E company. As time went by other companies were purchased that used different CAD packages (one of them being CoCreate). I was hired, 3 years ago, to support all the engineers and help them all move to Pro/E as the main CAD tool. I have heard many different sides of every story. I have recreated hundreds of CoCreate parts in Pro/E to help the Pro/E design teams work with the models that the CoCreate team created originally. Just to point out, I said recreated not translated or imported.

Now, back to the reasons:

- The original question points to a lack of experience with Pro/E. Maybe, even an effort to get out of having to use Pro/E.

- I hear all the time that CoCreate is a different mindset then Pro/E so the engineers cannot switch because they will be unproductive.

- There are many ways to model the same part, but it comes down to personal preference.

- All CAD tools have pluses and minuses. Nobody can send out a blanket statement like: CoCreate is better than Pro/E.

- All modeling mindsets have pluses and minuses and are clouded with personal preference rooting back to the CAD tool that the person has the most experience with.

- From looking at our models (yours might be different), I would have to conclude that the freedoms CoCreate gives allows for poor modeling practices. Models I have seen in CoCreate are inconsistent from side to side, holes are misaligned, dimensions are carried out to 20 decimal places, geometry can not be manufactured, geometry gets cut away and new stuff added leaving weird geometry that is hard to manage, the list goes on.

- Many of the projects the CoCreate team works on gets to a certain level of completeness and then gets outsourced when it comes to the details and drawings. The companies that do the outsource work have voiced complaints to me about the quality of the CoCreate parts that they have to recreate in another tool.

- I have some preference to the history in Pro/E, because I like seeing how the part was designed and like to be able to edit the original sketches to modify the part. But, at the same time I sometimes I get frustrated with old history messing up what I am trying to create.

- While trying to create features in CC I have continual problems with them failing. So, Direct CAD can also have problems in that regards.

- In my oppinion Parametrics is something modeling cannot do without. If I specify that I want a hole to be 1 inch from the edge and then change the shape of the part that dimension must hold to my original design. Not stay were it was. If I move a hole, the fasteners in the assembly must move with it. I should not have to go back and move them manually. I know CC has a Parametric module, but the CC guys have told me they do not see the benefit.

I could probably keep going but I will leave it there for now.

I think that any engineer can learn to use Pro/E, just as you think any engineer can learn CoCreate. It all comes down to person oppinion and experience. If someone cannot put aside a mindset to learn a new one - they are not putting enough effort into it. It all comes down to what is your job, and what does your boss want you to do. I would put more effort in learning CoCreate, but I am supposed to support Pro/E. If that directive changes I will change. I might still hold onto my personal ideas, but I will change.

It is all up to the person to try and stay in the box or get out. It is not driven by the CAD tool as your original post suggests. No offense intended.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Paul,

Thanks for your input, and sharing us your broad experience in CAD.

But, when keeping the discussion away from personal product knowledge or features and functions, I would like to take it up one level.

On the question "what would you use to put a nail into the wall", most people will answer 'a hammer'.

But wat if it is not that obvious if it's a nail or a screw?

Let say that your boss just asked you to hang a picture on the wall.

The hammer will do for both a nail or screw, if that's the only tool provided by your boss.

Your process can improve if you can see if it's a nail or not, and you can choose the tool that fits the job best.

So it all comes to the processes on what tool is best. The technology should support that process.

What I wasn't trying to say is that engineers aren’t smart people.

But the processes could be more productive if they only knew what was possible.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Sorry if I miss understood your question. I guess I read it as a direct slam on people that know and like the mindset of the parametric CAD tools. And, a statement that CoCreate is an inheritently better tool.

I forgot about the aurgument to try and compare the CAD tools to completely different hand tools. That is a fun one, but I do not think it apply correctly. I do not think that you can honestly say that one tool is a screw driver and the other is a hammer - or one is a saw and the other is an axe. In my oppinion they would both be hammers, just different styles of hammers.

It all comes down to what someone is comfortable with - yep I am going back there. You might like the feel of one in your hand, someone else might like the claw shape of another. Who is wrong? Are you going to tell the other person that your hammer is better because it fits your hand the best?

I say we use the tool our employer has purchase for us and not complain about it. If your company is in the market to change tools, then by all means try and get the one that fits your hand the best. It all comes down to mindset and how willing the person is to change and apply something new.

I do understand that CoCreate is great for design generation, but Pro/E excels at detailed design. If PTC can put both tools together to create a product that excels at both it would be a thing of beauty. If Pro/E was revised in such a way that my CoCreate users and my Pro/E users could use it and feel comfortable I would be sooooooo happy. Maybe even my SW users would like it to and stop pushing for that. Go Project Lightening Go! (Go Grease Lightening) ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I find the "tone" of this question to be objectionable. Perhaps the original poster didn't intend for it to be taken that way, but if so, the OP needs to consider his use of language much more carefully before making this sort of commentary.

For the record, I am a long-time user of Pro/ENGINEER (with somewhat less experience in several alternative packages - IDEAS, Inventor, etc).

Also for the record, I use Lightwave, Maya, ZBrush, Mudbox, and so forth. TOTALLY different types of applications, with totally different sets of capabilities, and used for totally different purposes.

The question is... are we creating ENGINEERING work (which must be completely defined, completely inspectable, and completely repeatable)? Or are we creating "artwork" which can be adjusted "by eye" just so it "looks right?"

For doing a mechanical design, it's nearly impossible to do this sort of work in non-parametric types of tools. You simply can't do proper engineering work without the explicit, math-driven description of the critical working elements. You choose the right tool for the job.

On the other hand, if you're trying to come up with a shape for, say, a modern-art sculpture... Pro/E (or any other parametric math-based modeler) is really not the right tool for the job.

The phrasing of the OP's question is perjorative. It infers, not so subtly, that prefering the right tool for the right job is somehow "closed-minded." That the sole reason that some people prefer using parametric design practices is because "that's what they know" and that some other approach may be equivalent, or better, in any given circumstance.

His later comment about "hammers and screws" further drives home this perception on his part. But even that argument falls apart, because he then limits himself to "one tool or the other."

Here's the answer. If you have a design which you ever expect to need to modify, or to do variations on, or even adjust tolerancing on, and if that design needs to physically interface with any other design element, parametric solid modeling is the preferred approach. If you want to create complex, "organic" shapes, parametric solid modeling is not the perferred approach.

The two can be blended. Engineers have been doing this for as long as the tools have been available. There are many ways to blend "organic sculpted shapes" and "mathematically precise designs." In my experience, this is typically best handled by creating the "complex shapes" in a separate tool, and using the output of that tool as a "sculpted template" where the complex elements are copied into the new engineered part.

It would be very nice if there were a practical way to implement "Maya/Lightwave" style modeling into "3D parametric CAD" tools directly. However, there's a fundamental issue there, and as far as I'm aware, this has yet to be resolved. See, it's CENTRAL to proper engineering work to have clear, communicable, REPEATABLE mathematical definitions for engineering features. "Free form" modeling does not really have any allowance for this yet. Yes, it's possible to provide the full mathematical definition of every non-uniform rational bezier spline surface, I suppose... but this seems a bit unwieldy, doesn't it?

I have no doubt that the two types of modeling will, eventually, "merge." I think this will happen sooner rather than later... perhaps even starting to see mainstream use within the next five years or so. But as of today, the problem isn't that "parametric CAD users are closed-minded," it's that the two tools simply serve totally different, and in many ways contradictory, functions.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello Cary,

I have to agree with most of what you said in your post, up till the end. The OP was comparing Pro/E specifically to CoCreate. I agree that other tools like Maya are absolutely different from Pro/E and in fact they are different from CoCreate as well. CoCreate was created to be a tool to create ENGINEERING work. It just does not hold to parametrics or history. The CoCreate catch phrase is "It is like a block of clay. Just start molding it" or something like that. What the idea is, is that someone can pick up a model that someone else was working on and immediately start changing it.

I Pro/E you have to look back at how they created the geometry then figure out how to changing it within the intent it was originally created. Both approaches are valid, but CoCreate allows mistakes that Pro/E does not.

One thing that is cool about CoCreate is that you can take an IGES or STEP file that was created in some other CAD tool and start modifiying it as if it were a native CoCreate part. No history, so no need to worry about it being imported geometry. If there are not geometry errors it will be good to go.

One of the problems is that as you are creating the initial ideas you can be hacking stuff off and putting new stuff on. Then when it comes time to create the engineering detail you have weird geometry that is legacy to one of the original hacks. Or my biggest complaint is that the aligned hole from side to side are no longer aligned.

For me I think there are many benefits to CoCreate, but the lack of Parametrics and intent manager are two things that make it not the tool for me. I think that engineering needs to be more constrained and precise than CoCreate allows.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I grew up with Pro-E and still love it, I'm now using Seimens NX 6.5 which has parametric modelling and direct modeling called Syncronous technology. I can tell you this combination is the best thing since sliced bread. At first I thought it would be good for modifying imported 'dumb' data and it is. Then I thought it would be good for making fast changes to complex history based models or models that have been modelled with a different design intent, lets face it Design intent does change during development and it does work.

These direct modelling adjustments are also parametric in their own right and are part of the history tree they can be suppressed and treated like any other feature. Then I started to realise that I could use the direct modelling methods to model in a whole new way this is seriously powerful. I could even tag these changes onto the end of a model and 'keep a record of all the changes made to the model. I'm sure PTC will look to put these types of features into Pro-E and believe me keep your minds open I'm sure you'll learn to love them and and then you'll find you just can't live without them!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I used CoCreate for a long while before I started using ProE. A combination of the two would be welcome if they can pull them together in a rational manner

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

My personal thought is that a combination of CoCreate and Pro/E is what they are working on with Project Lightning. We'll see on the 28th when they have the announcement.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Looks like CREO will allow us to use both Parametric and Direct modeling together.

This is powerful if you think of different ways it can be used. Many people only think of the Direct approach for conceptual designs and move to parametric when you have decided on the direction. This is one of the ways it will work and with CREO, going to the parametric side of it is automatic.

But there are many other ways the combination can be useful.

Example:

We design a product in Parametric Modeling and hand it off to Foundry Engineering. They run some Fluid Simulations and find that some cross sections are not large enough and restrict the metal flow that will cause Casting defects.

Foundry Engineering can open the Direct Modeling and push/pull the edges of the features to make them larger and eliminate the trouble areas. The run another Fluid Simulation to prove the change will provide a more effective design and hand it back to Engineering. Engineering pulls up the Direct Model using the Parametric Modeling App in CREO and can accept or reject the changes. If you accept the changes, the Direct Modeling changes and features become Parametric features. This will increase productivity big time.

Another Example:

A Design Engineer sends the finished Parametric model to the Engineering Manager. The Engineering Manager knows how to use Parametric modeling, but really only wants to tweak some things and maybe add some features quickly. This can be done in Direct Modeling, hand the changes back to the Engineer and they are converted to Parametric features.

I know there are many more examples where both technologies working together can make a difference.

I think it's a fantastic idea.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It's funny the religious battle the OP has re-awakened. Granted his language implied that dynamic modeling is better than constrained modeling. But some of the defensive responses from the Pro/E users are laughable. I am a long time CoCreate user - we started with ME10 / ME30 and were on board for SolidDesigner 1.0 all by HP in the beginning. But we also have Pro/E- we're at about a 5 to 1 ratio of CoCreate to Pro/E seats. Pro/E at the time was basically worthless (if you ask me). Both products and approaches have come a long way since them. But I have always thought the original product names were very telling "pro ENGINEER" and "solid DESIGNER". Invariably our Pro/E users are Engineers and CoCreate is much easier for our Designers. In our R&D / scientific apparatus environment, speed in modeling, the ability to completely change direction in the middle of the development, and the ability to reuse and modify other geometry, whether created in house or from outside, all made direct modeling the clear choice for our CAD standard. So it was surprising and a little scary when PTC bought CoCreate a few years ago. And I thought the schizophrenia they showed was entertaining (simultaneously touting the acquisition of the "best in class history based modeler" while renaming the CoCreate Dynamic Modeling marketing term to Explicit Modeling). If you ask me CoCreate was always Dynamic Modeling and Pro/E was always Constrained Modeling.

I do have to say the idea that you cannot use direct modeling for Engineering work is preposterous. Ultimately the resultant topology of the part is what defines it when it is instantiated in reality - in other words made. Both products allow for the creation of precise topology and therefore both can be used to create Engineering designs. I do agree that the direct approach allows the creation of imprecise and/or bad models as well as the ability to incorporate organic or product design features. One has to pay more attention to snapping and good modeling practices to produce accurate designs in CoCreate. This doesn't mean that constrained models are inherently better. It just means that it takes a degree of skill to operate either product and get good results. Also I wanted to point out the incorrect implication by an earlier reply that suggested all surfaces in CoCreate are splines. CoCreate is a non-uniform rational B-spline modeler. Non-uniform comes from the fact that it supports analytic surfaces (planes, spheres, cylinders, cones, and toruses) in addition to the splines which are required for all sorts of blends as well as organic surfaces. The powerful topological based modification algorithms rely on analytic surfaces all the time and also some embedded history information (like how a blend remembers where the edge originally was so that you can easily delete it or modify it).

From my experience, the liabilities of being forced to put your design intent into the model (the constrained method) is only apparent in two cases: 1. flat out extra time and effort to create the model (measured in terms of numbers of clicks or individual actions the operator has to do in order to model the required topology), and 2. the inability to make changes that violate the original design intent (captured in the constraint hierarchy). We have seen large projects come to a grinding halt when what seems like a small change needs to be made, but it is buried so deep in the structure and has so many dependencies that even the most skilled Pro/E user cannot easily resolve the issue. So I think the direct method is better for the conceptual design phase and/or working on other peoples models. The constrained method is better for mature designs and production designs were the up front effort of capturing the design intent pays off in the ability to handle the rippling effects of small variations on the design. I agree with another earlier reply that there is a great deal of satisfaction when you've set it all up and you make a small change (that doesn't violate the hierarchy), and the whole system reconfigures itself and the revised drawings fall out with nearly no effort - wow!

It is true that the base product of CoCreate doesn't let you do constraints. It is also true that the add-in module that lets you apply them isn't so great. You can turn it on and force two holes to stay aligned for example, or to maintain the distance from one side. But it is kludgy and not very robust. However it is very surprising how much you can do with topology methods alone. The direct modification algorithms Germany came up with are very mature and powerful. It really is no big deal to just grab the two holes and move them simultaneously when you need to. And many "features" can be recognized by the topology they are comprised of, requiring no history to grab them and manipulate them as as a unit intelligently.

The Creo demo did show off a lot of promise of blending the two paradigms. Like the NX demos I have seen, a blend of the two methods can be very powerful. I very much appreciate that PTC looks to be finally ditching the Pro/E interface. It helps to have a consistent look and feel over the different personalities the software will have. And this is a chance for them to streamline the interaction in a way they were never able to completely fix with Pro/E, even the latest build. I am optimistic at this point.

Returning to the OP's topic, and having seen the hints of what Creo will be like, I think it will be a learning experience for both direct modeling users and parametric modeling users. It is a brave new world. They will both have to get un-stuck in their thinking. Maybe there will then be peace at last in the CAD wars. So say we all.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It is certainly possible to fully control parts and assemblies parametrically in some Direct Modeling tools (CoCreate is the most capable one today). Capturing design intent is not something that is only possible in a traditional history-based environment.Here is a video I created some time ago showing this capability in CoCreate:http://www.youtube.com/watch?v=PNjwiKGbw58 All of the geometry I used in this video came from Pro/E through STEP (completely unintelligent geometry). In CoCreate (Creo elements/direct) there is no limit to the ability to parametrically control geometry - regardless of where the geometry comes from or how it was created. You can add this intelligence during model creation of afterwards. Add it when it makes sense and only add what is needed. Here is another video that further supports this concept: http://www.youtube.com/watch?v=bXxv2HVnunw

The big difference between parametric (history-based) and direct (history-free) is in the inherent parent/child relationship that comes with the history tree. There is no concept of this in Direct Modeling. But that doesn't mean that you can't parametrically define relationships. In history-based modeling the relationships are solved linearly through the parent/child relationship. In "Creo elements/direct" these relationships are solved synchronously (simultaneously). Siemens ST uses similar technology, but they rather make many parametric assumptions whereas in CoCreate a user is more specific about the relationships that are defined.

Paul

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Paul, long time no talk!

I have to disagree with the glowing impression you make of the parametric capability in CoCreate. Yes you can make it work. But as I stated before, it is kludgy and it is not robust. I have tried to make parametric relations (mostly on the assembly side) which are completely valid mathematically but the solver is unable to resolve it. Sometimes it just isn't able to handle completely consistent sets of constraints you throw at it. There are times where the assembly parametrics are key in CoCreate like when you are trying to do a sophisticated animation. Without them, you would be unable to deliver even some very simple animiated sequences, usually when you need something to rotate around a specific axis.

Also I would disagree with your statement that there is no concept of parent-child relationship in CoCreate. It is right there in your structure browser!! This is an integral part of working with CoCreate because it allows you to manipulate individual parts or subassemblies as units because of the parent-child relationships defined by the assembly structure. The biggest difference between this and the parametric assembly relationships in Pro/E is that in CoCreate they are incredibly easy to change, just drag and drop. A lot of Pro/E users when they are given CoCreate to use complain about the fact that if they Mate / Align a part to another part in CoCreate, it doesn't STAY and they hate this. That is BS. You just put the two components into a common assembly and then as long as you reposition that assembly, the parts DO maintain the Mate / Align you applied. The flexibility of dragging things into and out of assemblies to define the parent child relationships is a key functionality of CoCreate. Without it, you would be hopelessly re-doing the same work over and over again since you don't have the constraints (in the default product) to define those relationships.

This whole discussion makes me wonder how they are going to handle this in Creo? Will you still be able to drag and drop to create your parent child relationships as you do now in CoCreate?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello James. Yes, it's been a while. Great to see you participating in these discussions.

Your right, I probably make it too glowing with what you can do with the parametrics in CoCreate, but it certainly has some useful capabilities. Relatively speaking, parametric control of geometry in a direct modeling system is still immature. But this technology is certainly going to progress quickly with several companies working hard on it. I hope PTC continues to stay ahead of the competition on this.

You are right considering the parent/child relationship of a typical assembly structure. I was more referring to the parent/child relationship in the data structure of a typical history tree, i.e. recording the modeling steps in such a way that an early step (parent feature) can influence a later step (child feature) - order dependant. In CoCreate sometimes blends can be order dependent, but in direct modeling the modeling operations are simply not recorded in a structured (parent/child) relationship.

With Creo, CAD assembly development/management won't change much with elements/pro or elements/direct (Pro/E, CoCreate).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi, guys

It’s nice to see that the long lasting “confrontation” between parametric modeling and direct modeling is still alive. Let me point on one aspect of this problem that, to my mind, is underestimated by the community.

To begin with, I would like to insist that the integration of these two approaches to 3D modeling is absolutely must to have for any advancement in the CAD industry that pretends to revolutionize the CAD market (though I do believe that somebody may have a different opinion).

But I would like to say even more – this long waiting integration is already successfully implemented, at least in 2D world.

Let’s forget for a moment that we are living in the 3-dimensional space. Imagine that our world is 2D.

Now let’s consider the 2D Sketcher of Pro/E not as a tool for constructing features of 3D parts, but as the 2D CAD application of itself. Then you can notice that the direct modeling approach is fully implemented here (for the 2D world we are living now). Certainly, for this 2D world the direct modeling is quite simple – you just need to drug-and-drop whatever you want using mouse (but this is everything you need for “direct modeling” in 2D case). On the other hand, you, certainly, have all the parametric capabilities in the Sketcher of Pro/E (actually, it is the 2D Sketcher, where all the “parametrics” of Pro/E is mainly live).

In other words, Sketcher of Pro/E has everything necessary and sufficient for both parametric and direct modeling on 2D plane (at least until the sketch is simple enough and Sketcher’s solver is able to resolve it in real time while you move a mouse).

The question is – if this marriage of the parametric and direct modeling resulted in such a happy family as the Sketcher of Pro/E (and similar sketchers of Pro/E competitors – SolidEdge, SolidWorks, Inventor, etc.), why not to repeat this experience in 3D world? That is, why not to implement the full functional 3D Sketcher?

Let's imagine an application that has the same look and feel as CoCreate (with all its direct modeling tools) but having additional tools for setting all reasonable geometric constraints on 3D entities (analogous to 2D constraints of 2D Sketcher). And, certainly, it should have a capability to resolve in real time the corresponding system of equations while you are applying the direct modeling tools (shift or rotate some faces, modify surfaces, and so on, and so forth)…

Ay, there is the rub! The systems of equation that have to appear from the constraints in 3D space are definitely must be much more complicated than those we have in 2D Sketcher. Besides this, as you surely remember, in Pro/E we are using “dirty trick” – I mean the famous “feature based approach”. Pro/E doesn’t solve the system of constraint equations for the whole 3D part. Instead it solves the hierarchic sequence of the smaller systems of equations for the features of this part (more precisely, for the underlying 2D sketches of these features). It simplifies calculations but it causes all the drawbacks of the history-based modeling.

To my mind, if we want to merge direct modeling and parametric modeling we need to go away from hierarchic features (i.e. say “farewell” to history-based approach) and resolve parts as a whole.

You can consider this “feature based” trick as a genius approach. Moreover, the whole philosophy was developed behind the feature based approach - they say that this hierarchic tree of features is the expression of the intension of a designer. But, to my mind, the reality is more prosaic. I guess that this trick was invented in the early days of Parametric because there was no way out. At that time there was no chance to solve really big systems of equations.

Actually, this is the point that I wanted to pay attention to. From those glorious times of the PTC’s childhood a great progress was achieved in solving really huge systems of equations (with hundreds of thousands of variables) similar to those resulted from geometric constraints. Having this in mind, I would like to ask everybody who has any guesses on the topic:

- Am I right that the root of the problem of unification of the direct modeling and parametric modeling in 3D lies in the developing a really powerful solver that is able to resolve (in real time) big 3D complexes?

- Am I right that any real breakthrough in the CAD industry have to be based on the development of such an advanced solver?

- Should we expect such a breakthrough in Creo 1.0 (or 2.0, or 3.0 …)?

I do apologies, if somebody considers my tone “objectionable”. I have a great respect to PTC as a pioneer of parametric modeling and wish any success to the declared revolution. My only intension was to describe the landscape as I see it…

Frankly speaking, when I'm thinking about Creo initiative, these questions bother me.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I would say you want to be able to ignore the history (not do away with it), but also keep it when you want to. I don't think the answer is to try to resolve the whole part at once. The improvements in regeneration in Pro/E over the years and the power in CoCreate topology based modifications are both due to advancements in solving local operations. From the parametric side you need to be able to treat branches of the feature hierarchy as units that can be de-coupled and reinserted more easily than Pro/E allows. The cut, move, insert of a topological feature branch is exactly what the CoCreate code base is great at. This was demonstrated in the Creo demo. It looks like they extracted the smart topology based methods in CoCreate and are using it to carry along the parametrics when they are "fully contained" within the target topological feature. I'm sure it is much harder than it looked and that that demo was very well rehearsed! But it did look promising.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

@James Osborn

I just learned more about Direct Modeling from your post than I have from all the videos and information I can find on PTC's site.

I have been using Pro/E (Parametric Modeling) for over 16+ years. I never understood what Direct Modeling was or how it could fit into our process. I started to understand more and more about it, but never from an actual user who had real world experience with it.

I think it's exciting to see Parametric and Direct Modeling working together in CREO. I can see where our company would use Direct Modeling for some things and Parametric Modeling for others. Using them together, I think is a good way to get the best out of both system in order to improve our process.

I appreciate the information you shared and I am looking forward in learning more about the Direct Modeling approach. I have always been open minded about learning new things, so it's never a problem for me to sit back and learn something different.

I have a question for you.

Do you think having the Parametric Modeling App and Direct Modeling App in CREO is the best way to do things, or would you rather see CREO allow for both modeling systems in one package?

As it stands right now, it seems I will need to purchase Direct Modeling Apps for everyone in our process that could benefit more by this approach and have Parametric Modeling Apps for the others. I can see where many of my users could use both and now I have to buy more licenses (Apps). 😞

Just wondering what your thoughts are on this.

Thanks

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I would definitely rather work in an environment where both methods are available. I am guessing the way they handle the Creo Direct modifications when the model is opened in Creo Pro is that the direct modifications are like soft constraints. They are there, inserted automatically, as needed, so the model can regenerate in Creo Pro. So using both methods together might be like using direct modifications when you want, explicit constraints when you want, and sometimes switching soft constraints to explicit ones or vice versa. CoCreate lets you make many direct modifications using methods that look a lot like modifying a fully constrained Pro/E model. I presume they use the smart topology methods and just display the dimensions like they are constraints, but they aren't really. I would assume Creo Direct would use the same topology methods, and perhaps leave soft constraints in the model for later use by Creo Pro. This is all conjecture on my part.

From my perspective, I would rather have as few constraints as possible, only when I want to capture some design intent. There are a lot of cases where it would be nice even when doing direct modifications, to set up a few hard constraints you need. If it really is true the products will be totally separate, I would find myself in Creo Direct most of the time. Presumably this means it wouldn't enforce any hard constraints you put on the model in Creo Pro, so what would be the point? Conversely if I worked in Creo Pro most of the time, using soft constraints most of the time and a few hard constraints as needed, it would be a pain to have to save out and re-open in Creo Direct just to make a direct modification when I want.

I'd like to be in Creo Pro/Direct (if I might coin a new name) that would be parametric, use soft constraints most of the time, allow hard constraints as needed, AND support direct modification methods. In some cases like the demo, using a direct modification might simply result in cutting out or copying a feature branch in the history, and reinserting it somewhere else. Other times, it might be too hard and convert many constraints into soft constraints. I can't imagine it would be easy to really have both methods integrated into the same product, but that would be optimal.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi James

Thank you for your reply. May be, you are right and Creo demo looks promising (actually I enjoyed this presentation and like the idea of rebranding - the name Creo is really good). But this promise is too long-lasting.

Don't you think that not a big progress in Siemens PLM Synchronous Technology (ST1 -> ST2 -> ST3 -> ...) and the troublesome road to the marriage of CoCreate and Pro/E are the signs that this approach based on "solving local operations" has some inherent restrictions?

If you want to reach the real freedom to transform one 3D design into another (somehow similar but, may be topologically different) 3D design, you need something more powerful than local operations. And this more powerful "something" is the system of geometrical constraints covering the whole part (and the corresponding system of 3D equations), which requires a really powerful solver to resolve these equations.

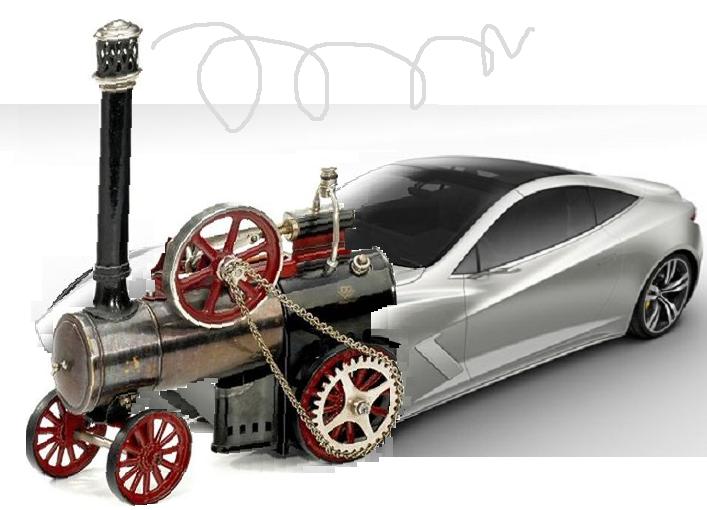

If you want to design a supercar you can't use an engine developed 25 years ago. You need a totally new engine, most likely, based on the new principles.

My feeling is that this is the mainstream of the further CAD investigations, and such a powerful solver (a "new engine") is not a dream but the reality of the nearest future. I do wish to PTC to move in this direction. The new brave world is there...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I though create did have a brand new engine built from the ground up. That is what I heard PTC say at least.

Just because CREO opens Pro/E files, does not mean it's using the 25 year old Kernel. From what I understand, the Kernel in CREO is brand new and patented. Maybe I am wrong here. Not sure.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I guess we really don't know how much is new and how much is old code in the new product. I find myself concerned that the continued support of two product lines (standalone CoCreate + Pro/E, AND Creo Pro + Direct) cannot be long for this world. Unless they were able to abstract the kernel methods from CoCreate so that it can be "plugged in" with either Creo Direct or stand alone CoCreate, then it means that the old CoCreate interface will go the way of the dinosaur. This would be a shame IMO.

A more advanced system able to resolve local operations and have a more global approach like you are thinking might be possible. I just think that when the model complexity gets large enough, a purely global approach will bog. I hate bog. It is precisely how nimble that CoCreate is at making drastic changes that is what is so great about it. Throwing away the purely direct method in favor of a more sophisticated kernel that supports both methods might result in a parametric modeler with SOME direct modification abilities but at the cost of speed and flexibility. If you do your direct modification in a whiz bang fashion like the Creo demo showed or that CoCreate already does all the time, and then you have to sit there and WAIT a few minutes while the global solver gets all the parametrics straightened out, I'd say YUCK!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Recently, when I did a search in Google for something like "new CAD revolution" and expected to see there PTC with Creo, I found there some guys that call themselves Cloud Invent. It looks like small start-up on the very early stage of their life.

They seem to saw my post in this blog and even use my cartoon with the car (I don't object). I was amazed how close their vision of the future parametric CAD to that of mine - especially in the unification of parametric and solid modeling.

It's nice to realize that my dreams on this Great Unification are starting to implement in some CAD application.

I don't know how far they are from some workable prototype (may be, far enough) but there are two videos that compare sketcher of Pro/E with their sketcher. And it seems that they have some very powerful engine in their hands.

With such a powerful solver it might be possible to implement the 3D sketcher that will have parametric and direct modeling capabilities in one workspace (as we have it now in 2D case).

Were I among the top PTC managers, I would pay attention to these guys. It seems to me that they are on the right road...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It seems that a major downside of the 3D direct Modeling, is the ability to transform the model in a not so "natural" way; turning it to a more graphical/computer approach to modeling rathen than a real representatin of real life situations.

In the REAL WORLD you can not remove faces or surfaces, for example of a CUBE and find something hollow inside, but you can DO IT in Direct modeling !!!

A physical object in reality is solid inside and not hollow

I am afraid there is a recipe here that tolerates errors, misalignments and merging of surfaces

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

How you can suggest that being forced to "consult your blueprint before beginning your model" (a direct quote from a Pro/E instructor during a beginning Pro/E class), so that you can make sure you have consistent constraints, is somehow more natural than whittling on a chunk of material the way you would if you throw it on a milling machine and start cutting, is beyond me! Generally speaking I find that CoCreate facilitates manufacturable parts because the basic methods used to create and modify geometry are very much like manufacturing operations. In many cases, when you go through the steps to create the model, you are in a sense doing dry run of making the part in the shop.

Seriously you parametric minded Pro/E users are really in denial if you continue to assume that direct modeling is somehow inherently inferior to constrained modeling. As I previously stated, both methods have pluses and minuses and both require a degree of skill to achieve accurate results. The ability to turn a solid model into a face part in CoCreate "could" be the result of poor skills. CoCreate is pretty good at dealing with this in two ways: Firstly when you turn a solid into a face part, the icon in the Structure Browser changes from a solid cube into a surface patch. Also the face colors change from the default buffed aluminum to a blue color. There are tools to create new surfaces between existing 3D edges and 3D curve tools to create new edges in space. Secondly, when you stitch a face part back into a solid by manually inserting the faces where holes lie, it automatically turns the part back into a solid, the default face color changes back to aluminum, and the icon changes from surface patch to solid cube.

The ability to turn a solid model into a face part in CoCreate can also be entirely intentional. It can be used by the expert user in some situations to model geometries that are difficult using the standard tools, whether they came through constrained or direct methods. And it can be used to heal or fix problems with imported geometry from outside packages - regardless of how the geometry was created. In some cases with strange "special" geometry, it can be faster to construct a part from scratch using the surfacing and curves available in CoCreate. Once it is turned into a solid and checked with Part Check, it is just as good as a model created using the solid tools and can be used to create drawings or drive CNC tools.

So if you are going to incorporate direct methods into the product at all (apparently the goal of Creo), then turning solids into face parts (and vice versa) is not only not a downside, but is in fact advantageous in many cases.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I think the title more appropriate would have been: Would a pro-e user shrink to 3-D Direct CAD?

In such critical applications as Engineering, being foolproof should be the main objective of any CAD software. The fact that C.C. allows the user, either intentionally or not, to modify/change the original concept without regard to its original perception, sets up a situation when a blueprint/drawing may have edges, faces, curves and confusing lines unaccounted for and not related to the real geometry. One may argue, that this is a user’s fault, however the fact that You Can Do It, in itself represent a dangerous freedom that may be very costly later on. One reason why constrains exist, we may argue about it, is to show what the limitations are and how to prevent user screw-up’s.

Co Create has a very similar approach to the design as Rhino and Rhino and Pro-E currently compliment each other very well. I do not really see room for CC here. One may argue why not use Rhino for Mechanical Design?