Community Tip - Stay updated on what is happening on the PTC Community by subscribing to PTC Community Announcements. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: project tool in sketch, there has to be a bett...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

project tool in sketch, there has to be a better way!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

project tool in sketch, there has to be a better way!

ok here's my issue:

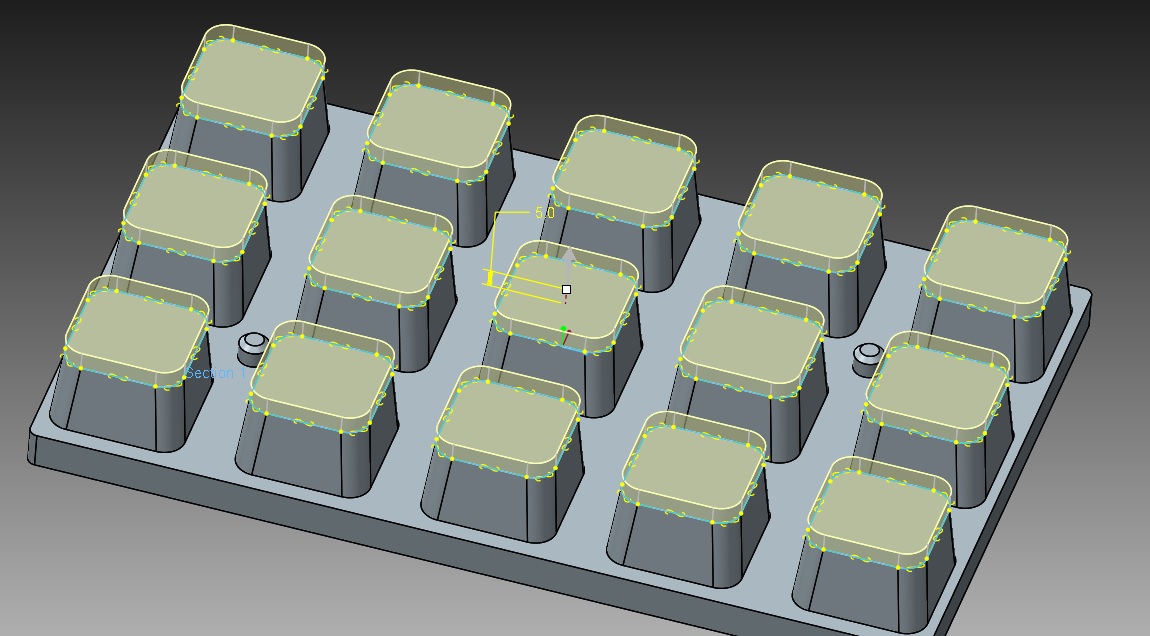

I have a lot of tapered bosses on a plate. and I need to extrude from there top surface strait up rather than continuing with the taper. "think a block of chocolate"

so I could go back and remake the part so that it has the shape I want. in this case that wont work

but instead I go into sketch and project the boarders of the bosses to give me the projection lines.

project -> loop ->

click a face -> (that's 1 done)

click a face -> click next -> ( that's 2 )

click a face -> click next ->click next -> (3)

click a face -> click next ->click next ->click next -> ( 4)

see where I'm going with this.

its a really slow way of doing it,

surely there must be a way to go project and then go , this face , this face , this face , this face , this face , this face, done

projected lines selected

extrude

or a project everything on this surface button

if I can do it in other cad packages i.e. solid works or inventor and its pretty standard then why isn't it in Creo.

am i missing a secret command or is there just no way to do this?

note: in this instance ref pattern isn't an option as this block is cut from another part, and its too simple to program something in relations as that would be a waste of time as well.

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

Solved! Go to Solution.

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I tried to recreate your problem and I couldn´t.

In native files a good solution is to copy the surface and the use the thicken command.

On imported files the Project/Loop is also a fast solution.

You can even use udf´s or mapkeys to speed up the process.

Watch my short video, maybe it can help you.

Jose

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Sure, you make one and pattern it but for the most part, yes, tedious repetition is part of Creo... and WF... and Pro|E.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

yup, that's what i was afraid of.. (

http://images.socialnewsdaily.com/wp-content/uploads/2014/01/double_facepalm.jpg

ill just add that to the list of things lacking in creo.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Perhaps you could:

- intersect the solid with a plane through the top surface (a bit dodgy given that it's theoretically touching the plane rather than passing through it);

- extrude the curve resulting from the intersect?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You could create a plane at the mid point where the taper and straight extrude meet. Create a sketch on that plane for one of your chocolate blocks. Taper extrude towards the plate. Then select the same sketch and do a regular extrude in the other direction. Group the extrudes for the block and pattern it. Always use pattern for repetitive things, or find a way of making the feature so you can pattern it.

- James

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi, i am not sure this speeds things up, or simplifies the process, but did you consider copying the 'top surface' set & then 'thicken' the required amount?

John

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You can do it in Flexible BUT it does not seem to be any quicker.

The quickest way is probably to remodel it from scratch. Which is probably even quicker then picking all those edges.

Thinking about it, did you try (again you need Flexible) Pattern Recognition on the bosses? Then do one, then ref pattern?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

hrmn worth a look.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Honestly, unless you just expect the spoftware (ANY) software, to just do it for you automatically, I don't see an issue here. Copying a loop is quick, painless, and simple. What's the problem?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

sorry i probably should have explained better,

this is a piece of tooling which is cut out from the product, so there is no pattern data, its also a generic part so the amount of bosses will change dependant on the parent product it fits.

i was hoping that i could avoid making a relation driven from the parent other than the initial cutout.

and i could remake it so that the tooling drives the product, but thats backwards

what i was hoping for was something like the way you an right click several times to "select every line on the surface" when making fillets. or like in Solidworks where you can just click on several faces and extrude. from the profiles it automatically generates.

pro e just takes a long time to do certian things.

other things it's amazing at

but this is one of those things that grinds my gears a bit, that and not having a (center of 2 faces plane command) < again i might have missed that one as well.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Did you try: "Use Edge/loop" That'll pick all the entities on each "boss". You'll have to do that for every boss, but it's still quick.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I tried to recreate your problem and I couldn´t.

In native files a good solution is to copy the surface and the use the thicken command.

On imported files the Project/Loop is also a fast solution.

You can even use udf´s or mapkeys to speed up the process.

Watch my short video, maybe it can help you.

Jose

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

this looks like the go!

brilliant thanks.

edit:

the first solution for the native part works a treat ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Jose, nice!! I did this after watching your video...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

have you tried selecting top surface Edit>Offset>Expand

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This would have the advantage of keeping / extending the drafted side surfaces as well.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

If that's what you need, but he said he wanted them straight. However it does create corners that are not true radii.

I am still wondering if Pattern Recognition worked, if Gary has Flexible? I started trying to use it more, more recently and it works great for a lot of stuff I have tried it on. Because what I did above was only a few clicks to get what he was looking for.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Gary,

I´m glad you could make it easily. I want to share more options with you, but for these, you need Flexible Modeling module:

1 - With the Move or Offset Feature (works even with non-planar surfaces, the most powerfull way to do this)

Flexible Modeling ->Offset or Move ->RMB ->Create Side Surfaces -> Intent chain

Watch the video , very cool:

2 - Using Pattern Recognition (depending of the geometry, can be a nice option)

Jose