Community Tip - Learn all about the Community Ranking System, a fun gamification element of the PTC Community. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: swap a part in assembly for almost identical p...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

swap a part in assembly for almost identical part

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

swap a part in assembly for almost identical part

needing some advice.

i'm making some updates to production parts and i've copied the relevant sub assems and parts to a new folder and renamed them.

i have 2 sub assems but they both use the same case and cover.

both sub assems have the renamed case and thats fine but i've not has sub assem 2 open when i renamed the cover. this means the one sub assem is correct and one is not. what is the best way to get the renamed cover into sub assem 2. if i use the rt click and replace, the parts below the cover, in the tree, all loose there placements. this seems odd as the part is almost identical to the original and was just made using a copy of the original.

i've come from SW and this would be an easy replace and the mates would reattach but not so in CREO, still fairly new to CREO and still learning.

thanks

- Labels:

-

General

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

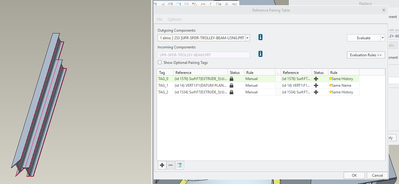

Use "replace" but click "unrelated component" and then select the replacement, then use "edit ref table" to select the references. Try the evaluate button first to see what it finds then any references not set, you manually select the reference on the new part.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

i've never used this before an im not sure what the evaluate table is telling me. i have 10 tags and 3 of then have yellow dots in the 1st ref column and then 2 have yellow dots in the 2nd ref column?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Can you post a screenshot of the table?

something like this (as an example)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

i've actually just removed the refs with the yellow dots and it appears to have actually worked.

1 of them was pointing at a feature that had gone for a wander. its not the best of models. there are assembly cuts that should really be part cuts and stuff like that.

hey its worked so thanks. do you know if there are ptc tutorials on this sort of thing?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

hi, table below.

tag 8 the cut has gone awol

tag9 and 10 seem to not reference anything in the graphics view

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I found a youtube tutorial. Not sure about others. Not sure if he used evaluate or just selected the references manually.

https://www.youtube.com/watch?v=8CTCl95ueaE

Right, the yellow ones in first reference column are missing (but known) references or otherwise potentially a problem.

When your parts are save-as, you get good results from evaluate.

When your parts are not save-as, you will have to manually pick the references. With a large assy, I've picked over 100 references manually. Still way better than dealing with the problems one-by-one after the fact when you don't know where the problem came from.

I agree the "qualilty" of the assembly you are working on makes a huge difference in how the whole process turns out. My assemblies are always the bad ones, LOL

Also, it's always a good idea to have the highest level assembly you can open in memory when you start a complicated replace since parts in a higher level can reference your replaced part in a lower level.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

excellent thank you

yeah my own silly fault for not having the all the assemblies open. highest level open and you get less issues, SW was similar.

and thanks i'll have a look at the tutorial.

cheers

![Creo Parametric - Replace by Unrelated Component [Tutorial] Creo Parametric - Replace by Unrelated Component [Tutorial]](https://i.ytimg.com/vi/8CTCl95ueaE/hqdefault.jpg)