Community Tip - You can change your system assigned username to something more personal in your community settings. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: warp tool bend axis location

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

warp tool bend axis location

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

warp tool bend axis location

still learning the warp too and need some help

i've got a rubber strap that is modeled in its moulded state but for the assemble it need both end bent down.

part is modeled with the csys at the center of the part.

the first end is easy to setup. bend axis sits on the top plan as this is the middle of the part, moved the pivot to one end so that the unbent part stays in its original position.

the second end is not so easy as i cant get the bend axis to sit on the top plane, if you click center axis is puts it half way through the now bent part. and moving the axis when you are looking normal on the end of it doesn't work. moving the axis when the model is at a strange angle is difficult to get it where you want. also what do the marquee refs do?

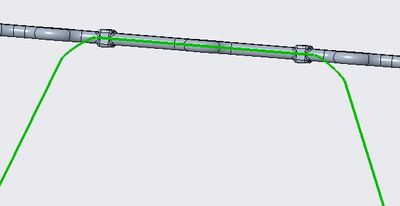

effectively, in the enclosed image how do i drag the marquee box up and down. i need the yellow bend axis to be on the top plane of the part.

any advice would be greatly appreciated.

- Labels:

-

General

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

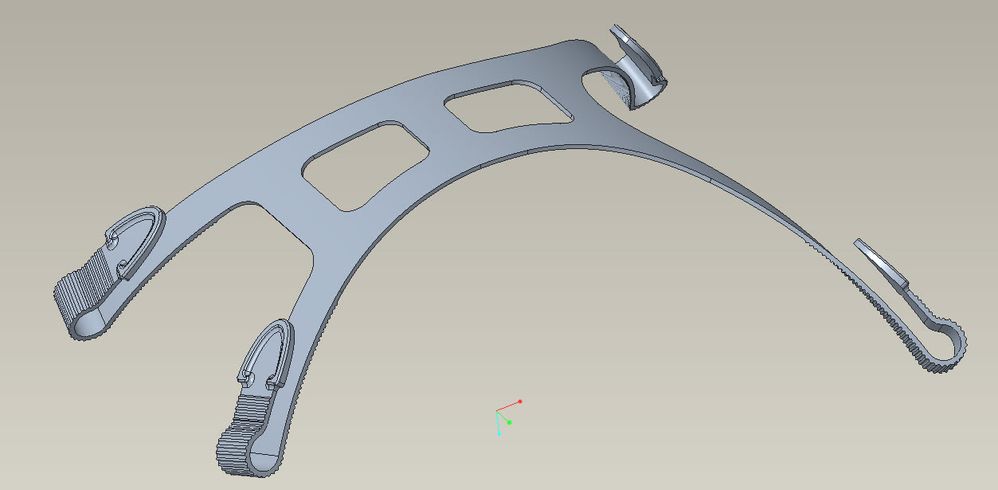

Warp is probably not the best tool for this. Check out spinal bend function to get your "bent" geometry of the part. I have used the spinal bend to do exactly what you are describing if I understand it correctly. With spinal bend you can parametrically control how the geometry gets "formed". Use of the perimeter dimension will make it it easy to control the bend zone and keep it where you want it. The example below was realized using spinal bend.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

hi,

yeah that works much better. much easier to control.

one quick question. if i try and from the whole thing with one sketch it does a really weird forming thing so i've needed to use 2 features. middle of part out in 1 feature and then the same for the other side.

is this how it work or can it be done in one operation?

thanks

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It may be possible to do it in one feature. I would need to see the geometry to determine that. The example shown above uses a total of 4 spinal bends to get the formed geometry seen in the picture.

From your description I gather that you want to bend it symmetrically about a symmetry plane. In that case it is more likely it could be done in a single feature. Are you forming it about a constant radius (cylinder) to bend each side of the part? This is where the perimeter dimension comes into play so that the developed length matches that of the flat geometry,

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

the parts looks great using 2 features. it is effectively forming over a box with chamfers and rads so its not a constant radius or anything like that.

its fine as is and was quick and easy enough.

thanks for your help

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Here is an example of how to use the perimeter dimension to bend and control the length so that the formed length is equal to that of the flat. This is bending over your described shape of a chamfered box bending both directions about the center in a single bend feature. It is a Creo 4 file.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

hi

thanks for this, however i have modeled my part and assembly around a centre plane so my sketch needs to go in both directions. the part at the centre is on the plane/sketch and both ends need to drop down.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The part I posted above is also modeled with the default datums as symmetry planes. The resulting geometry of the solid is the same using one or two bends but as you have found the orientation relative to the def csys is different depending on the start location of the drive curve for the bend.

To start the bend on the interior of a part you will need to use more than one feature to get your geometry as you already have done.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Excellent advice from tbraxton. Warp is very powerful, but more of a "free-form" modelling tool, not what I'd use for an Engineering tool from it's lack of constraints.

One other thing: Most times I don't use a spinal bend on solid geometry because of the distortion of the sides, normally what I do is spinal bend a surface, then thicken it. For the stuff I've done at least, it worked better.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

thanks i'll keep that in mind.

the bent part was just for a visual so any slight distortion is not an issue.

cheers