Community Tip - Learn all about the Community Ranking System, a fun gamification element of the PTC Community. X

- Community

- Creo+ and Creo Parametric

- Analysis

- Re: CWWARNING: ASSEMBLY CUT is entirely outside th...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

CWWARNING: ASSEMBLY CUT is entirely outside the model; model unchanged

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

CWWARNING: ASSEMBLY CUT is entirely outside the model; model unchanged

Hi,

I have an assembly with a pattern assembly cut . The pattern of hole "cut material" of different part of the assembly.

As a result when I regenerate the warning "WARNING: ASSEMBLY CUT is entirely outside the model; model unchanged" is there any way to resolve this issue?

I want to keep the model made of different part to get the hatch and the line correct in the drawing. and I can't make the hole at the part level as it's at the junction of two plates.

Thanks for your help

Nicolas

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

Solved! Go to Solution.

- Labels:

-

General

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

In this case you need to split the holes into two patterns to keep the message from appearing. The reason is as you described you have three parts in the list but the holes do not intersect all three parts. The message appears because for the first five holes they intersect two of the parts but for the third part in the list the holes "entirely outside of the model" since they don't intersect it. The same applies to the second five holes. One part is intersected the other two parts are not. If you're adding the parts manually to the list Automatic Update doesn't need to be checked. If you want, see what happens when you split the holes into two patterns. In each of the patterns only add the parts the holes intersect, for the first five there should be two parts in the list for the second five there should be one in the list. Otherwise, the warnings are going to continue to appear.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Nicholas,

I am not sure that I understand your question but I am going to guess anyway.

I avoid assembly cuts and instead use Top Down Design with a Skeleton and Publish Geom/ Copy Geom to make sure different features, such as holes, line up in the assembly but to ensure that I have the the references well controlled. This method uses the AAX module which is in our Enterprise SE licences. This method means that all features other than those copyied across are in individual part models not as assembly features and you can trace where that information comes from.

Specifically I suspect that your patterned assmbly cut does have some aspects of feature creation (one or more) which are completely outside the model(s) and usually I treat any such warning as a remimder to do things more robustly (hence the TDD approach).

If you do not have the AAX to do the TDD method you can still use things such as a patterned axis in the assembly which you use as a reference in the parts or the much older and still robust Master Modelling method where you make your first part in your assembly the master model and you make datum features such as planes and axes plus surfaces e.g. a surface cylinder (extrude) as the hole reference. You layer everything off in the Master Model and just turn it on when you need to use it for references. You will need to ensure your use of information from other models is allowed. You will need to be very careful not to get uncontrolled cross references but it is good practice to be careful with these anyway.

Hope I have explained this well enough and that it helps at least a little bit.

Regards, Brent

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Brent,

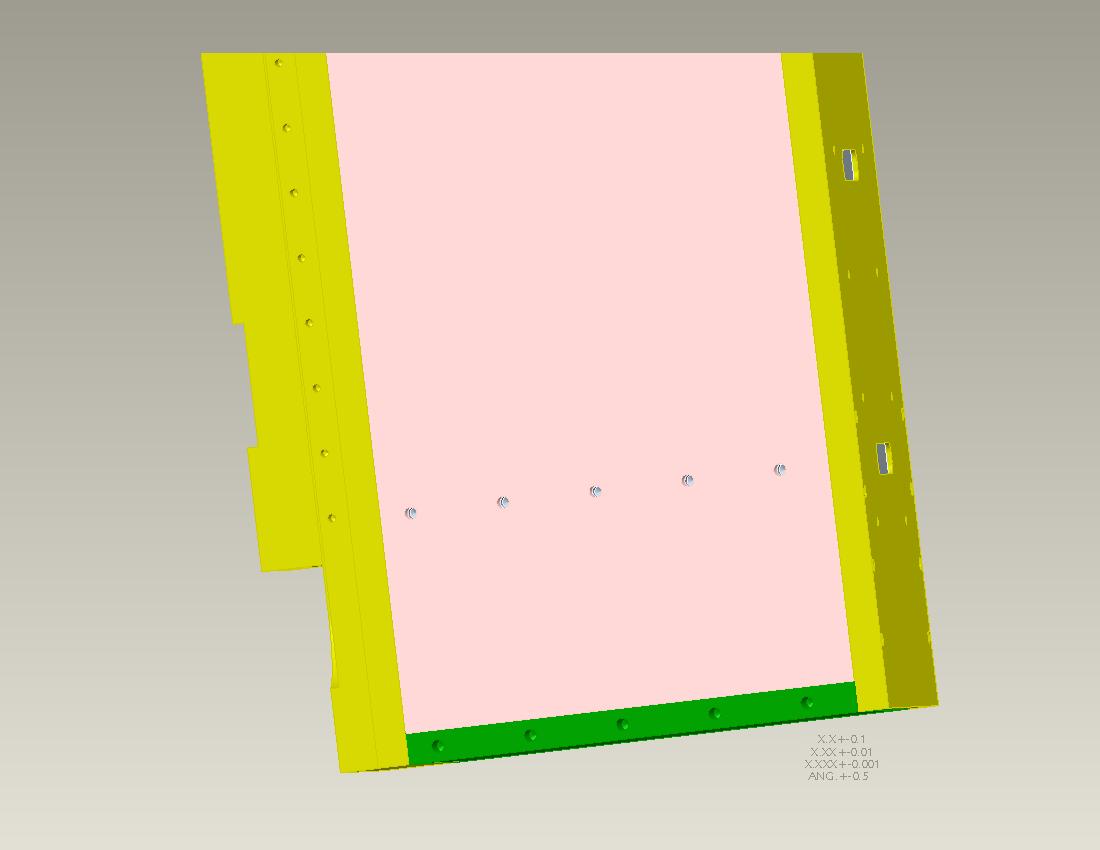

See the picture bellow . This is a welded fabrication I've added 10 holes at the bottom, 5 are cutting the pink and the gray part sand 5 are cutting the green part only.

Proe thinks the holes are outside the model? I can not add the hole in the individual part as multiple parts are cut and I would like to keep the welded fabrication as an assembly for drawing purposes.

Nicolas

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Based on where you are placing the assembly hole feature, if you where to extend the hole in one or both directions, does the feature intersect other parts? By default the feature will automatically add intersected parts to the intersect list. If when you first created the hole it intersects both parts but you redefine it later so it only goes through one you will get the warning because the parts are not automatically removed from the intersect list. Parts get automatically removed from the list only on initial feature creation or when you edit the definition of a feature a part is not initially in the intersect list (start the hole feature, go to the intersect tab, using the drag handle drag the feature depth, as it passes through parts the list will update to add or remove parts that the feature intersects). To keep the message from showing up go to the intersect tab on the assembly hole definition and see if you have parts in the intersect list you don't want the hole to go through. To remove items from the list uncheck Automatic Update and remove the items you don't want the hole feature to go through. When the feature regenerates the warning should no longer be issued. If you redefine the feature later check or uncheck Automatic Updates depending on your needs.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Kevin,

I have added the intersect part manually, and there is only the three parts involved in the list.

I suspect it because half the holes cut only two parts and the second half cut only the third one proe thinks some holes are outside the model.

I've tried to keep the automatic option ticked but the problem persist.

Nicolas

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

In this case you need to split the holes into two patterns to keep the message from appearing. The reason is as you described you have three parts in the list but the holes do not intersect all three parts. The message appears because for the first five holes they intersect two of the parts but for the third part in the list the holes "entirely outside of the model" since they don't intersect it. The same applies to the second five holes. One part is intersected the other two parts are not. If you're adding the parts manually to the list Automatic Update doesn't need to be checked. If you want, see what happens when you split the holes into two patterns. In each of the patterns only add the parts the holes intersect, for the first five there should be two parts in the list for the second five there should be one in the list. Otherwise, the warnings are going to continue to appear.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This is creating a problem with the holes notes it will be split in two, one for each pattern.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Why do they need to be in a single pattern?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

If the holes are made in one pattern the hole note in the drawing (3d note in the model) is made automatically and you can keep it parametric without having to create a variable to add all the pattern number.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

To me that's more of a personal preference than a problem since the note can be modified and still be parametric to account for both hole patterns. It just involves a little more to get the output right.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Do you know of a fastern methode than creating a new parameter with relation?

Thanks for your help

Nicolas

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

As far as I'm aware splitting the pattern into two, adding a parameter that is controlled by a relation, and modifying one of the hole notes to use the new parameter instead of the pattern_no parameter is the the only way to keep the warning from showing based on my understanding of your model is set up.