Community Tip - Want the oppurtunity to discuss enhancements to PTC products? Join a working group! X

- Community

- Creo+ and Creo Parametric

- Analysis

- Re: Creo Simulate - static analysis - links and co...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Creo Simulate - static analysis - links and constraints problem

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Creo Simulate - static analysis - links and constraints problem

Hi everyone,

I am currently trying to apply a force on an assembly, a delta robot, more precisely on its end-effector. The problem is that the stress/force is not passing through the different parts. It is like if the static analysis is only considering the part I applied the force on.

I have simplified this first analysis by bounding some parts, the one that are screwed together.

I have also not included the bearings for all joints, the idea was to link the parts without the bearings. For that, I have used the "Function Pin" of the constraints. The first joints of the delta robot are blocked axially and radially, then, all other joints are just blocked axially.

This method works on Catia V5.

Attached to this post:

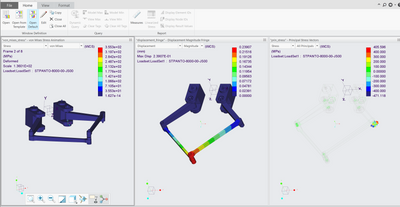

creo-study1-1 and creo-study1-2 : show the result of this wrong analysis.

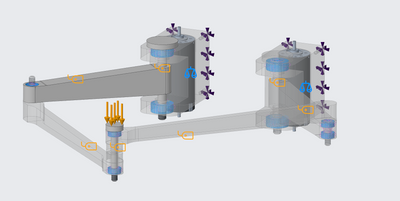

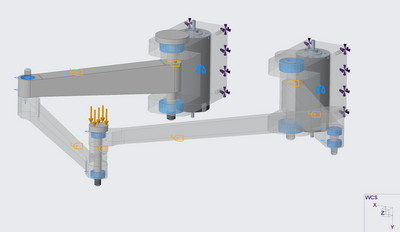

creo-study1-3 : shows the way I have constraint the joints, which have 2 bearings.

catia-study1-1 : this is the analysis on Catia V5

Anyone can help me, please?

Regards,

Julien

- Labels:

-

Simulate

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Can you specify the version of Creo Simulate?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

it is creo parametric 5.0.5.0, I do not know where to find creo simulate version.

regards,

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello All,

It seems that it is regarding a small load maybe you can edit the legend in Result windows by increasing the min value

Otherwise

Check if die assembly component constraint blocks the load distribution

Did you try with contact between touching components?

Best Regards

Oualim

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello,

I did try to modifiy the scale, but the behavior remain unchanged.

All touching components have a connection called "bonded" (Refine Model - Interface - bonded between two components).

This concept works on Catia, there might be another way to do it on Creo!?

regards,

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It appears to me that you are not setting up your constraints correctly. You should not have displacement constraints on the joints. If you need to release degrees of freedom at the joints I would suggest using beams to connect your joints and then releasing whatever degrees of freedom you want with the beam ends.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello,

In the Beam definition, I cannot define all the surfaces that would interact through the bearing. How would you do it.

In Catia, I have never included the bearing, a connection was defined manually, and I was then specifying that this connection is a rigid virtual connection (with the rotation unlocked). Then, only the created parts were deforming.

regards,

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You create a point and then create a rigid link (RBE2) from the point to the surfaces you want. You do this on two ends. Then you create a beam element that connects to the points and release the degrees of freedom of the beams as needed. Keep in mind that the X beam vector is along the axis of your beam.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello, I have been trying to do it your way, but something surprised me. I created 2 points, in each parts. created 2 rigid link, from surfaces to points.

Then, I tried to create the beam, but Creo ask me to specify beam section, it does not look like it is the right way. Am I doing something wrong?

Regards,

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I have use the beam function to reproduce a solid which looks like the bearing.... I don't know if this is the right way.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I tried to represent the bearing, it seems to work, i am going to try to open some DOF and give you some feedback

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

No you are not doing something wrong, create a new beam section that approximates the geometry and material properties of the real connection. IE if you have a 1mm shaft then make a solid beam section with a .5mm radius and assign a material to it.

In your picture below I would remove the central cylinder and replace it with a beam.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

he does not let me open the DoF Ry, creo consider that the model is not sufficiently constraint if I open it with this simple pantograph...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You can always run a constrained modal analysis with rigid mode search to see what DOF you haven't constrained.