Community Tip - Did you get an answer that solved your problem? Please mark it as an Accepted Solution so others with the same problem can find the answer easily. X

- Community

- Creo+ and Creo Parametric

- Analysis

- Re: Force to close a

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Force to close a

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Force to close a

Goodmorning,

I have a following question: Is it possibile investigate with Creo Simulate the value of the force in order to "close"

the purple solid against the Yellow solid.I need a non-linear analisys, right?

Thank you for your help

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

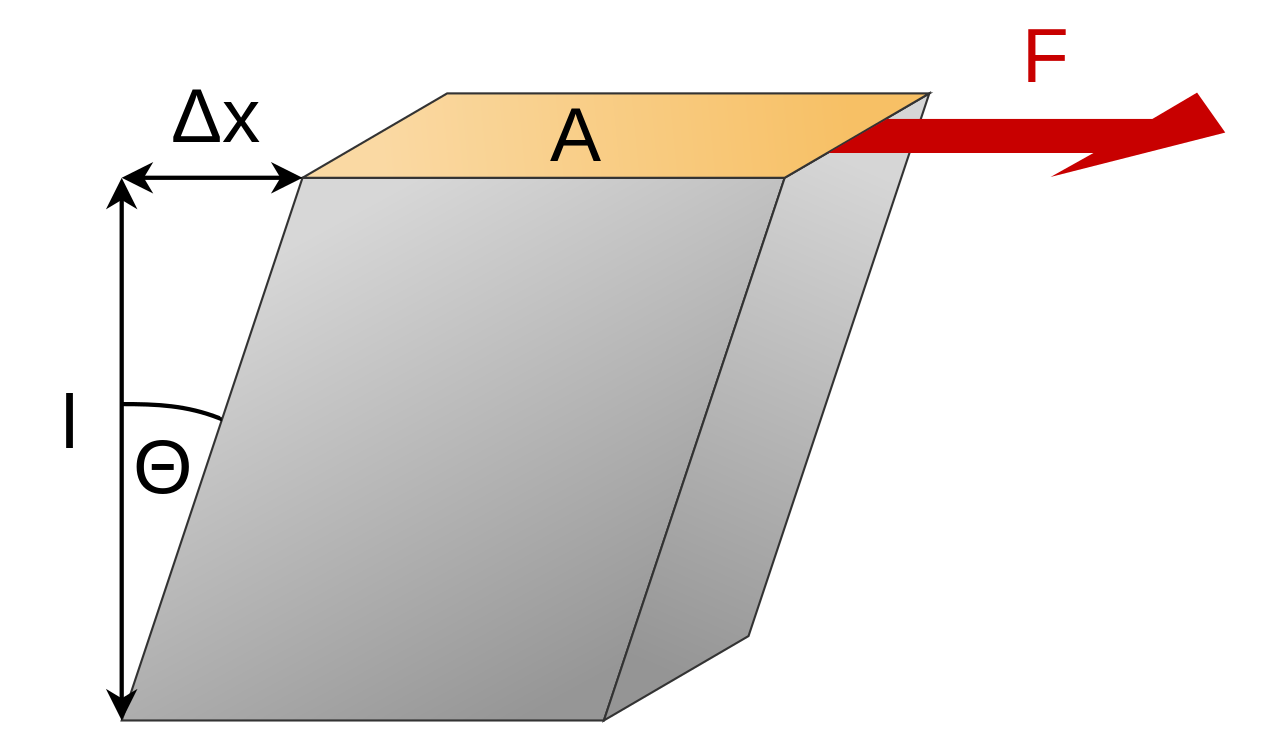

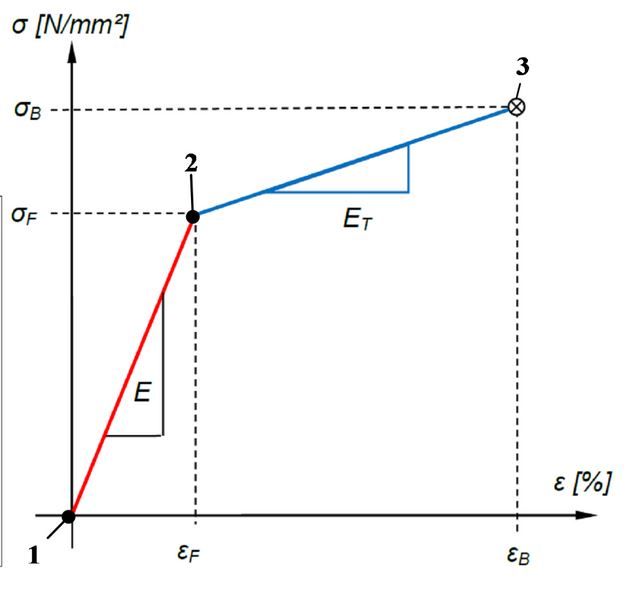

Yes you want non-linear. Large Deformation and possibly Elasto-plastic material

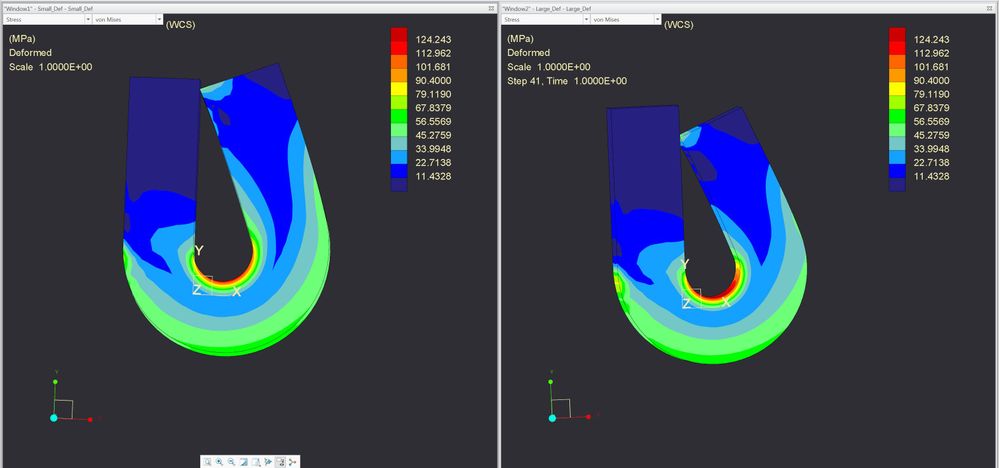

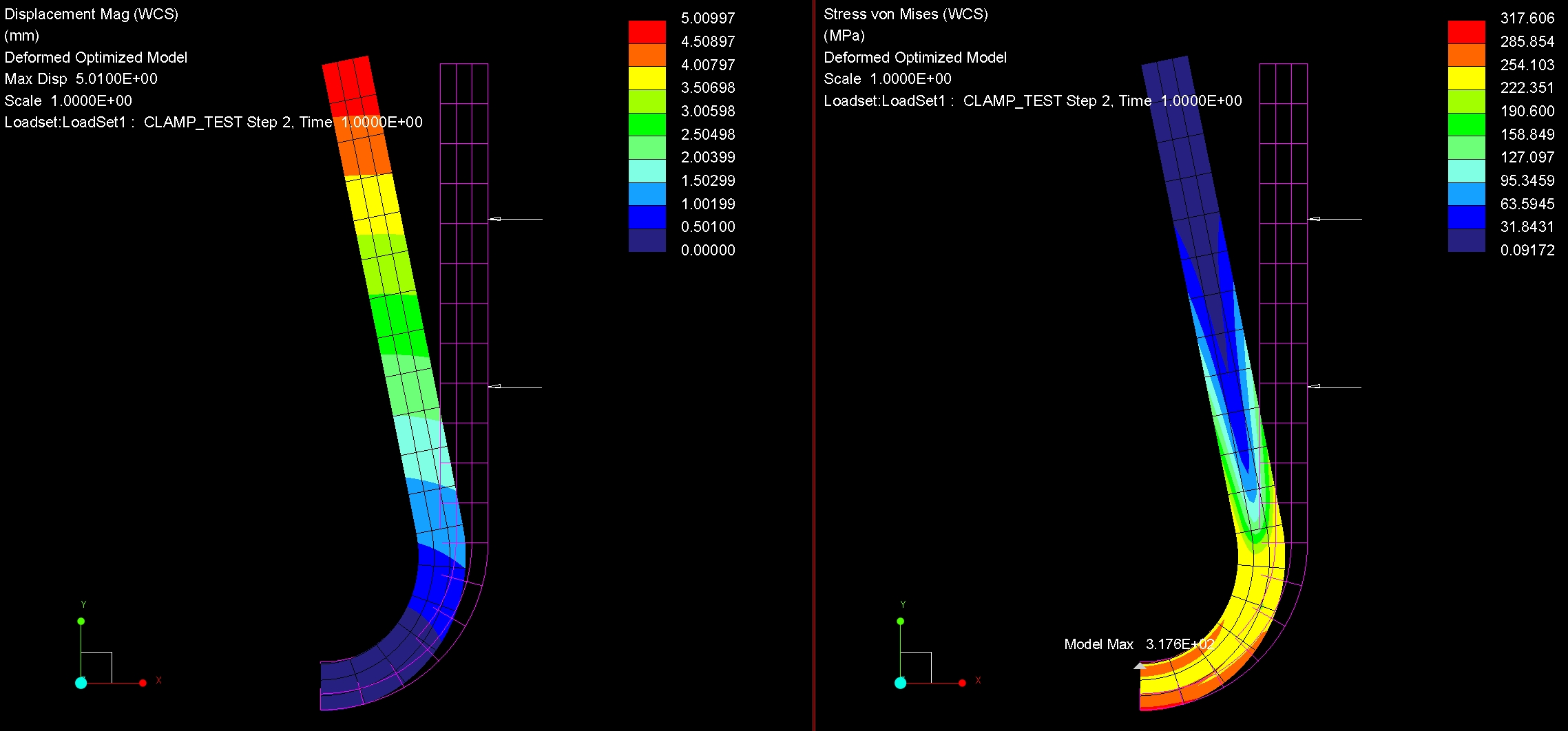

Here is the difference in small displacement and Large displacement (small on left)

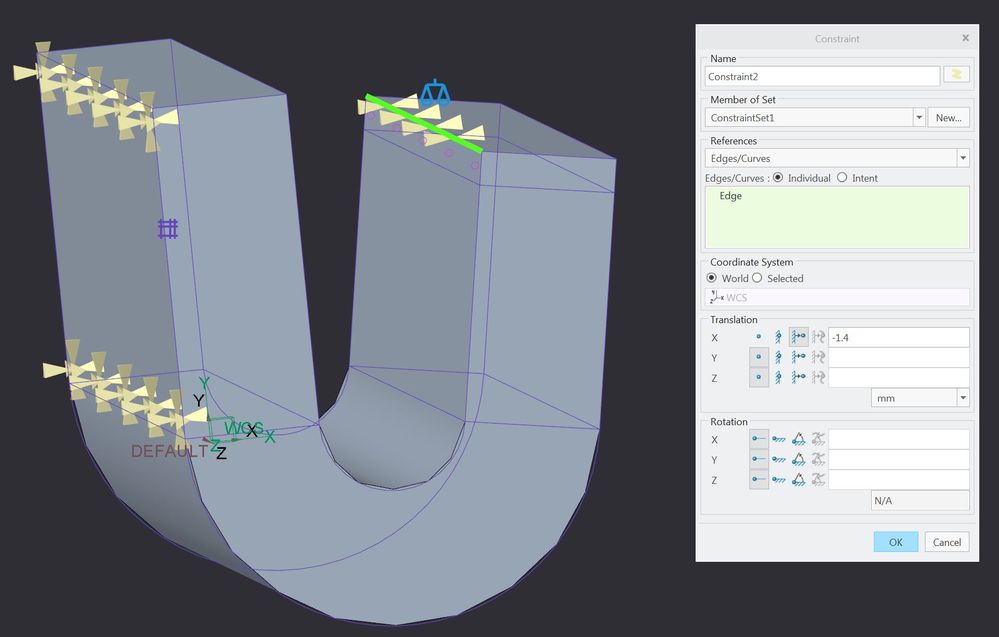

Here is how you do the 1.4mm deflection

Here is how you prevent infinite stress at the edge constraint... with a small region made rigid.

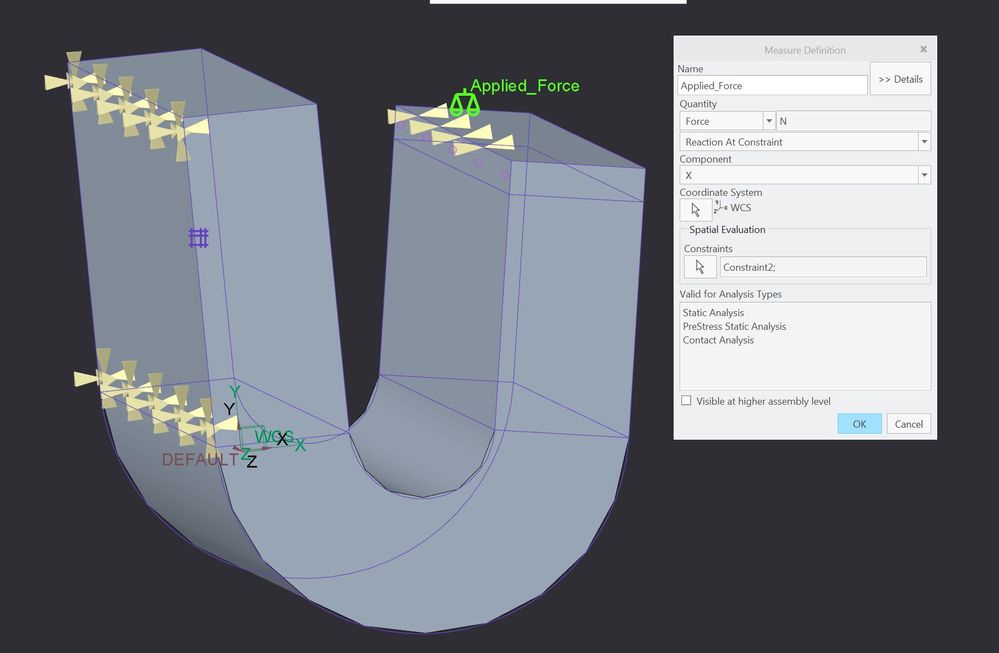

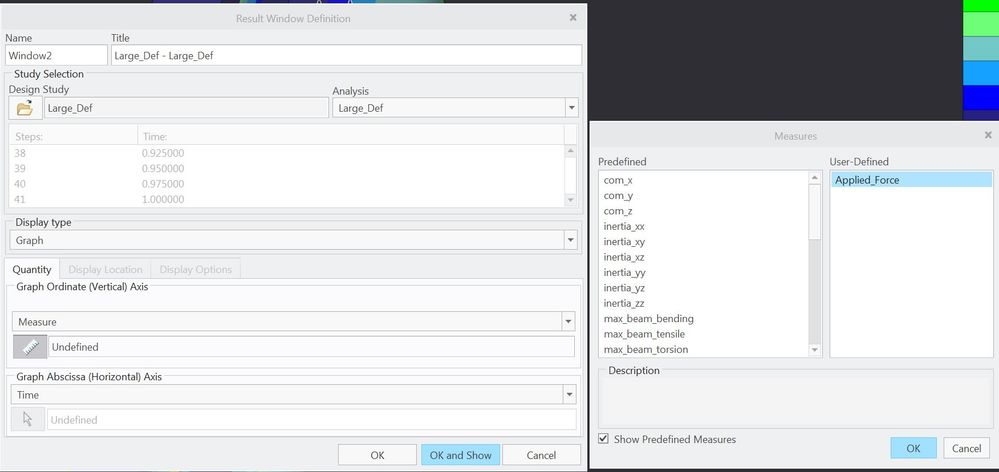

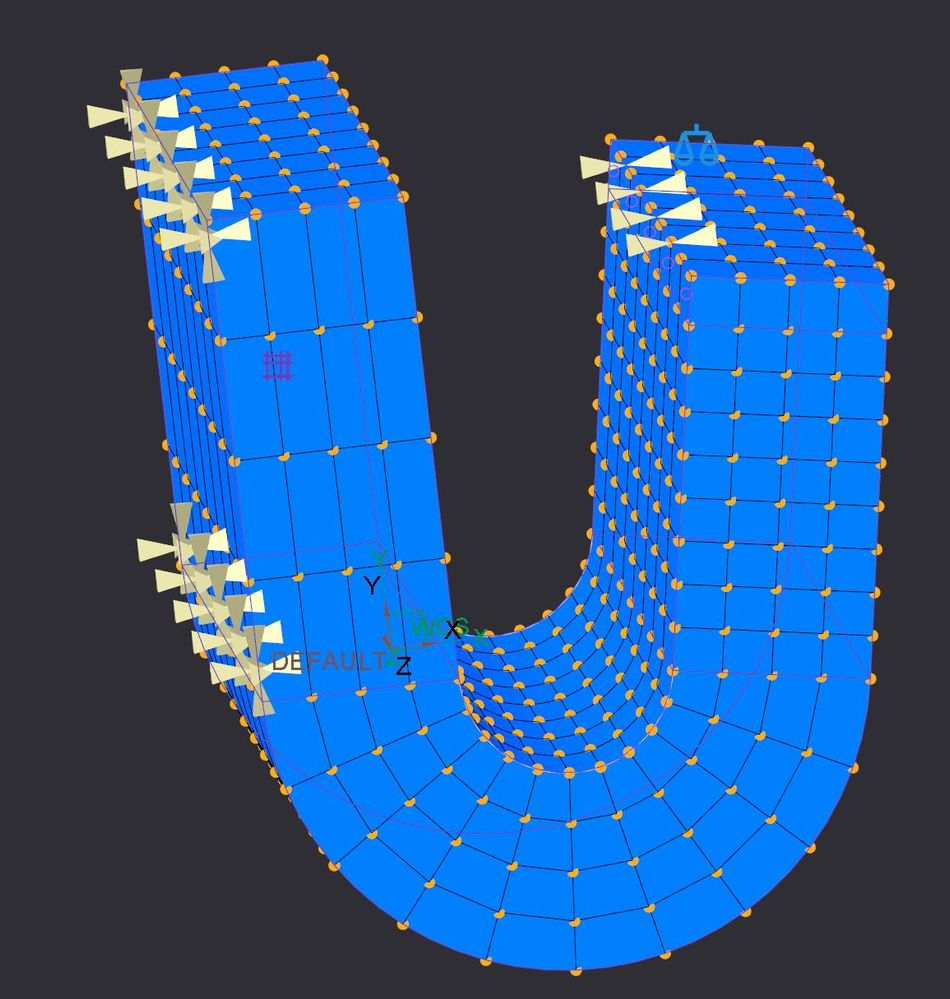

Here is the measure used to obtain the force.

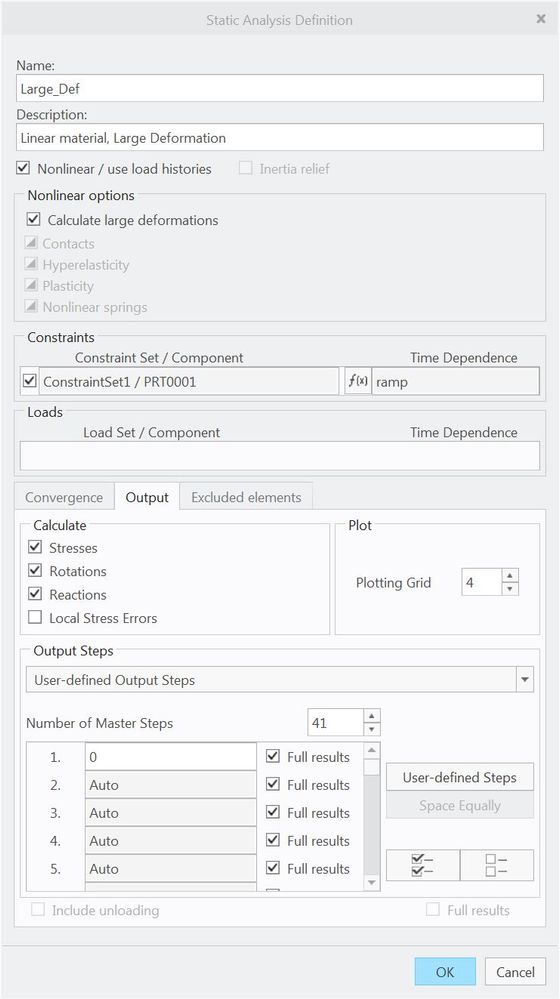

Here are the Analysis definitions. If using elasto-plastic material then Plasticity will have a check mark.

Plotting the measure vs. time

Final results. If stress is above yield then you should use ELASTO-PLASTIC material. Nonlinear material + non-linear geometry. Otherwise force is generally predicted too high.

Confirmation? Run this model with found force (48N in this case) in X direction as a load in place of the enforced displacement. Confirm max displacement about 1.4mm in X direction.

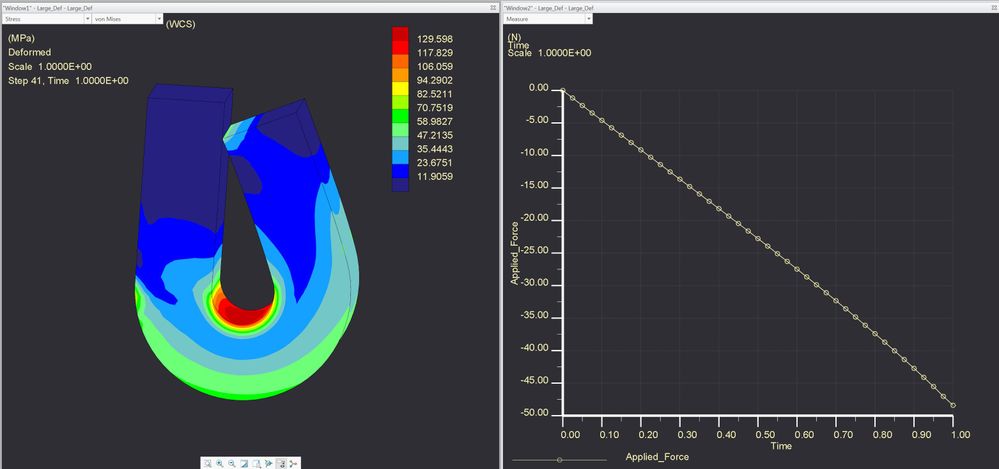

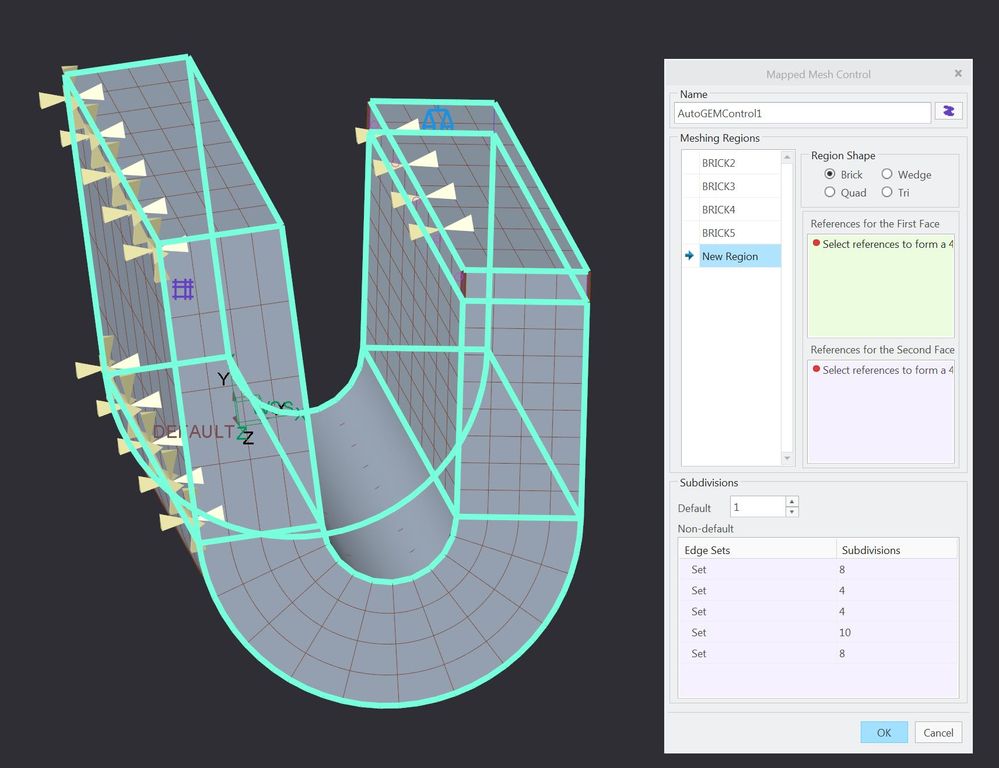

BONUS - I used a Mapped Mesh (not totally necessary but results are so smooooth!)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you for a good response

but I'm not able to open the file.....

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

That is why I had all the details... because not everyone is using the same version.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Simulate said me that costraint and rigid link on surface region to prevent infinity stress is incompatible...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This is OK. It is a warning, not an error. Only use caution when this message appears because you may be asking the model to do two different things at same time.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

What You do in your model? You used the same way or an other?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Same way.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi!

I used an elastoplastic material, but obtain this warning message with high stress

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

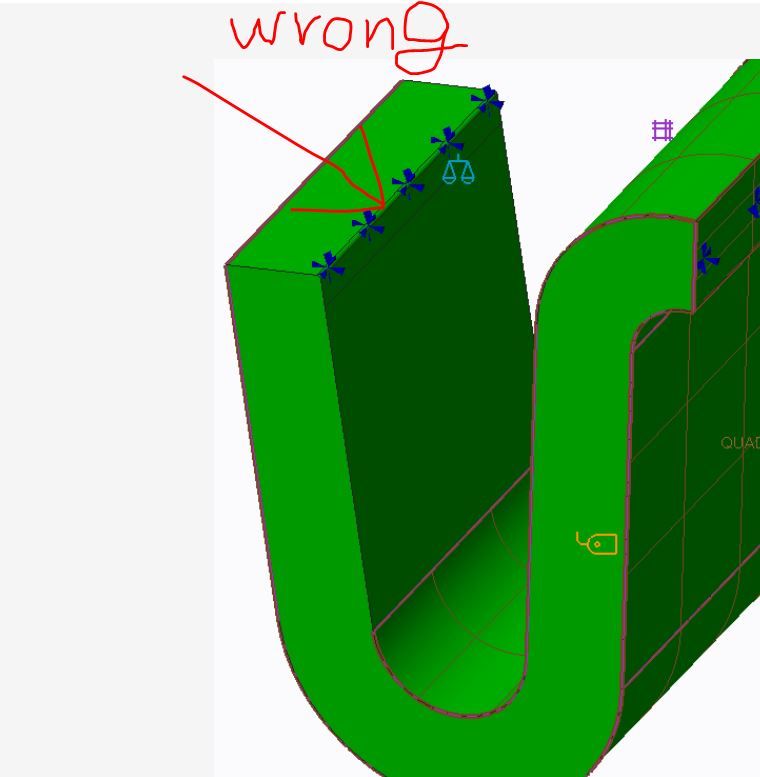

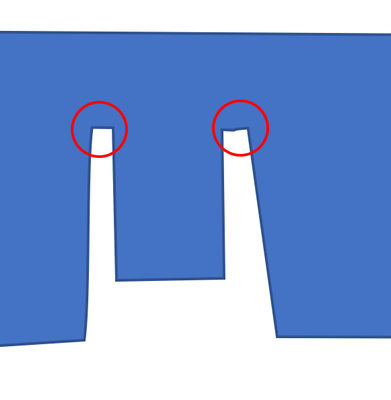

Please show more views of your model. Is there a location with a sharp inside corner like this?

All inside corners near areas of interest should have at least a small radius. For the plastic parts I work with 0.15mm radius is used. Compared to H-elements, P-elements are less forgiving. In H-elements the stress is averaged over the element size which hides the singularity until using smaller and smaller elements. For P-elements the order of the element captures the high stress with larger elements. You can artificially limit the order of the elements near singularities but I prefer a tiny, but realistic radius.

What strain is it reporting vs. what you expect? Are you using a force or an enforced displacement. With a force this same message often comes when the design cannot reach the load applied, sometimes even failing to finish the loadsteps. I also suggest to plot a measure of plastic strain or stress vs loadstep. You can stop the analysis and view intermediate results at each loadstep.

Finally element quality/number will affect the ability to model large strains. A mapped mesh with quads and more layers through the thickness will help capture larger strains without too much element distortion. A tetra mesh with large elements could contribute to the issue.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi,

I try to improve my model, but I obtain again high stresses;

I added a small radius where the displacement occurs and mapped mesh

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

no

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

In this way the values of stress down, but there is again the warning

"** Warning:

The stress is much higher than the yield strength of one of the

elasto-plastic materials in your analysis. Please review

your material properties and/or units."

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

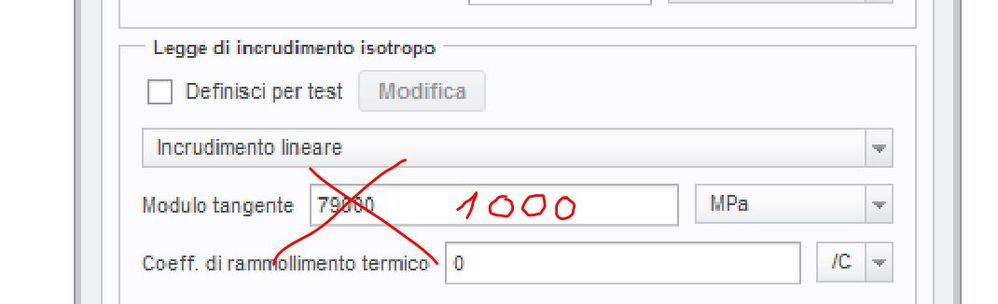

Where did you find this value (1000)?

The data sheet I mean.

Thanks

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

it's approximately, circa

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator