Community Tip - When posting, your subject should be specific and summarize your question. Here are some additional tips on asking a great question. X

- Community

- Creo+ and Creo Parametric

- Analysis

- Re: Is it possible to precisely specify Query poin...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Is it possible to precisely specify Query points, using coordinates, or planes?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Is it possible to precisely specify Query points, using coordinates, or planes?

Is it possible to precisely specify Query points, using coordinates, or planes?

It will be nice of using excel table, and create specific XYZ points.

I need to check the FEA stress, against strain gages.

Thanks,

Boris

Solved! Go to Solution.

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Boris,

When you ran the analysis, The analysis should have created a folder with the name of the analysis.

In this folder there should be a file called (Your_Analysis_Name.rpt). Open this file with a text editor.

In this file you will find the data your are looking for at the end of the file.

Hope this helps,

Don Anderson

Should look something like this:

Load Set: LoadSet1: PRT0001

Resultant Load on Model:

in global X direction: -3.731300e-10

in global Y direction: 7.743008e-11

in global Z direction: -2.000000e+03

Measures:

max_beam_bending: 0.000000e+00

max_beam_tensile: 0.000000e+00

max_beam_torsion: 0.000000e+00

max_beam_total: 0.000000e+00

max_disp_mag: 2.273793e-01

max_disp_x: 1.274006e-02

max_disp_y: -1.749406e-02

max_disp_z: -2.264426e-01

max_prin_mag*: -2.202082e+02

max_rot_mag: 0.000000e+00

max_rot_x: 0.000000e+00

max_rot_y: 0.000000e+00

max_rot_z: 0.000000e+00

max_stress_prin: 2.323141e+01

max_stress_vm*: 1.225728e+02

max_stress_xx*: -9.745248e+01

max_stress_xy*: 7.909744e+00

max_stress_xz*: 7.430658e+00

max_stress_yy*: -9.913390e+01

max_stress_yz*: 1.070902e+01

max_stress_zz*: -2.191157e+02

min_stress_prin*: -2.202082e+02

strain_energy: 1.765350e+02

Measure1*: 1.225728e+02

Measure2: 2.662682e+00

Measure3: 7.468690e+00

Measure4_PNT10: 7.497607e+00

Measure4_PNT11: 7.910385e+00

Measure4_PNT12*: 6.300263e+00

Measure4_PNT13*: 5.404658e+00

Measure4_PNT4: 5.468962e+00

Measure4_PNT5: 7.303314e+00

Measure4_PNT6: 8.184689e+00

Measure4_PNT7: 8.172292e+00

Measure4_PNT8: 4.504136e+00

Measure4_PNT9: 6.807737e+00

** Warning: The measures marked by an asterisk (*) were evaluated

at (or close to) results singularities. The values of these

measures may be inaccurate, and you must use engineering judgment

when interpreting them.

Analysis "Analysis222" Completed (11:02:18)

------------------------------------------------------------

Memory and Disk Usage:

Machine Type: Windows XP 64 Bit Edition

RAM Allocation for Solver (megabytes): 6288.0

Total Elapsed Time (seconds): 1.34

Total CPU Time (seconds): 0.61

Maximum Memory Usage (kilobytes): 8233989

Working Directory Disk Usage (kilobytes): 4096

Results Directory Size (kilobytes):

815 .\Analysis222

Maximum Data Base Working File Sizes (kilobytes):

4096 .\..\..\..\..\temp\Analysis222.tmp\kel1.bas

------------------------------------------------------------

Run Completed

Tue Mar 13, 2012 11:02:18

------------------------------------------------------------

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Boris,

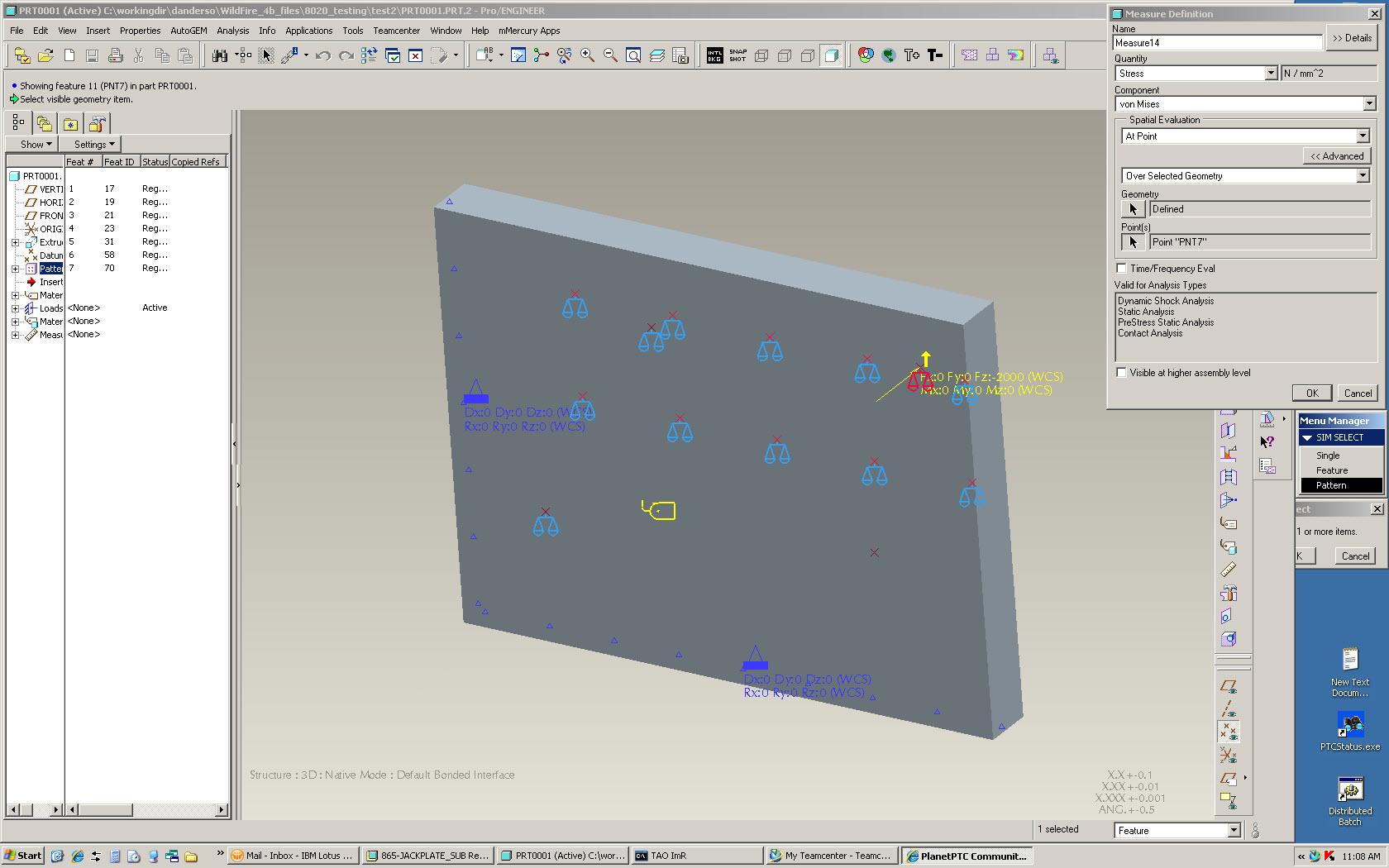

You might try using a Simulation Measure over Selected Geometry at Point. (see image below)

If you create your points as a pattern it will create measures for each of the points you have

defined in the pattern. (make sure to select the pattern)

You could then map the measure results in the .rpt file in the analysis directory to an excel file sheet.

Hope this helps,

Don Anderson

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Don,

Thanks a lot.

It is very helpful.

I created the pattern of the points, using CREO.

After that, I opened a Simulation, and created the measures from the points.

When simulation is finished, I cannot found .rpt file in the directory, and cannot see any measures results.

Probably, I missed something. Please, guide me step by step.

By the way, you already seriously helped me.

Thanks,

Boris

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Boris,

When you ran the analysis, The analysis should have created a folder with the name of the analysis.

In this folder there should be a file called (Your_Analysis_Name.rpt). Open this file with a text editor.

In this file you will find the data your are looking for at the end of the file.

Hope this helps,

Don Anderson

Should look something like this:

Load Set: LoadSet1: PRT0001

Resultant Load on Model:

in global X direction: -3.731300e-10

in global Y direction: 7.743008e-11

in global Z direction: -2.000000e+03

Measures:

max_beam_bending: 0.000000e+00

max_beam_tensile: 0.000000e+00

max_beam_torsion: 0.000000e+00

max_beam_total: 0.000000e+00

max_disp_mag: 2.273793e-01

max_disp_x: 1.274006e-02

max_disp_y: -1.749406e-02

max_disp_z: -2.264426e-01

max_prin_mag*: -2.202082e+02

max_rot_mag: 0.000000e+00

max_rot_x: 0.000000e+00

max_rot_y: 0.000000e+00

max_rot_z: 0.000000e+00

max_stress_prin: 2.323141e+01

max_stress_vm*: 1.225728e+02

max_stress_xx*: -9.745248e+01

max_stress_xy*: 7.909744e+00

max_stress_xz*: 7.430658e+00

max_stress_yy*: -9.913390e+01

max_stress_yz*: 1.070902e+01

max_stress_zz*: -2.191157e+02

min_stress_prin*: -2.202082e+02

strain_energy: 1.765350e+02

Measure1*: 1.225728e+02

Measure2: 2.662682e+00

Measure3: 7.468690e+00

Measure4_PNT10: 7.497607e+00

Measure4_PNT11: 7.910385e+00

Measure4_PNT12*: 6.300263e+00

Measure4_PNT13*: 5.404658e+00

Measure4_PNT4: 5.468962e+00

Measure4_PNT5: 7.303314e+00

Measure4_PNT6: 8.184689e+00

Measure4_PNT7: 8.172292e+00

Measure4_PNT8: 4.504136e+00

Measure4_PNT9: 6.807737e+00

** Warning: The measures marked by an asterisk (*) were evaluated

at (or close to) results singularities. The values of these

measures may be inaccurate, and you must use engineering judgment

when interpreting them.

Analysis "Analysis222" Completed (11:02:18)

------------------------------------------------------------

Memory and Disk Usage:

Machine Type: Windows XP 64 Bit Edition

RAM Allocation for Solver (megabytes): 6288.0

Total Elapsed Time (seconds): 1.34

Total CPU Time (seconds): 0.61

Maximum Memory Usage (kilobytes): 8233989

Working Directory Disk Usage (kilobytes): 4096

Results Directory Size (kilobytes):

815 .\Analysis222

Maximum Data Base Working File Sizes (kilobytes):

4096 .\..\..\..\..\temp\Analysis222.tmp\kel1.bas

------------------------------------------------------------

Run Completed

Tue Mar 13, 2012 11:02:18

------------------------------------------------------------

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The same information can be accessed by "Info:Status" on the "Analyses and Design Studies" dialog, "Summary" tab. "Log" and "Checkpoint" tabs give additional information about the Study.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You can also see the measure values in Results, with the Info > Measures command. On this Measures dialog, the Create Annotations button can be helpful.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks for the helpful posts. I can successfully do this for a point pattern on the surface of parts, but I need to get stresses inside a part. When I set up a Measure > Point Pattern inside a part, it meshes fine, but I get a fatal error when trying to run it, with messages like this:

'The measure "Measure1_PNT10" is associated with a point that is not associated with an element.'

I've also tried making those internal points Hard Points with an AutoGEM control, but that was no help.

I'm confused on why a Measure that would only be used in the Results stage (like an automated Dynamic Query) would interfere with running the model.

I've also tried to make a Results Graph following an internal Curve (defined as an AutoGEM Hard Curve). It meshes and the model runs fine, and I can pick the curve in the Results Window Definition > Graph Location step (it actually says "defined"), but it then errors saying there is nothing to show.

I've also tried inserting a cutting/capping surface inside the part (works fine), and tried to insert another cutting/capping surface perpendicular to the first (to define an internal line), but Results apparently only allows 1 cutting/capping surface. Of course, I can Dynamic Query on that cutting surface, but I don't see any way to pull off a repeated and regular array of data that way.

How does one get an a regularized set of stress results from inside a part? I'm using Creo 1.0.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

David,

I was able to do it using the following in wildfire 4. If you can pattern points at the simulation level you would be able to bypass creating the points on the surface in part mode and just create them on the volume region.

1. create a extruded capped surface inside the part of the area that you want to measure in part mode.

2. create a pattern of points on the extruded surface in part mode

3. create a volume region in Simulation mode matching your surface you created in part mode

You may have to use thru all (I had to in wildfire 4) for the volume region. This breaks the internal

surface so the points have elements to attach to.

4 create your measures using point pattern.

Hope this helps,

Don Anderson

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks, Don, for the helpful reply -- it worked! I did it a little differently (didn't make the capped surface) but got the volume region coplanar with the pattern points. It added many elements, but probably ok. Creo 1.0 is apparently the same as WF4 for no patterning at the simulation level.

I wonder why Measure points have to be nodes -- anyone know?

Thanks again,

David