Community Tip - You can change your system assigned username to something more personal in your community settings. X

- Community

- Creo+ and Creo Parametric

- Analysis

- Problem Shell Pair

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Problem Shell Pair

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

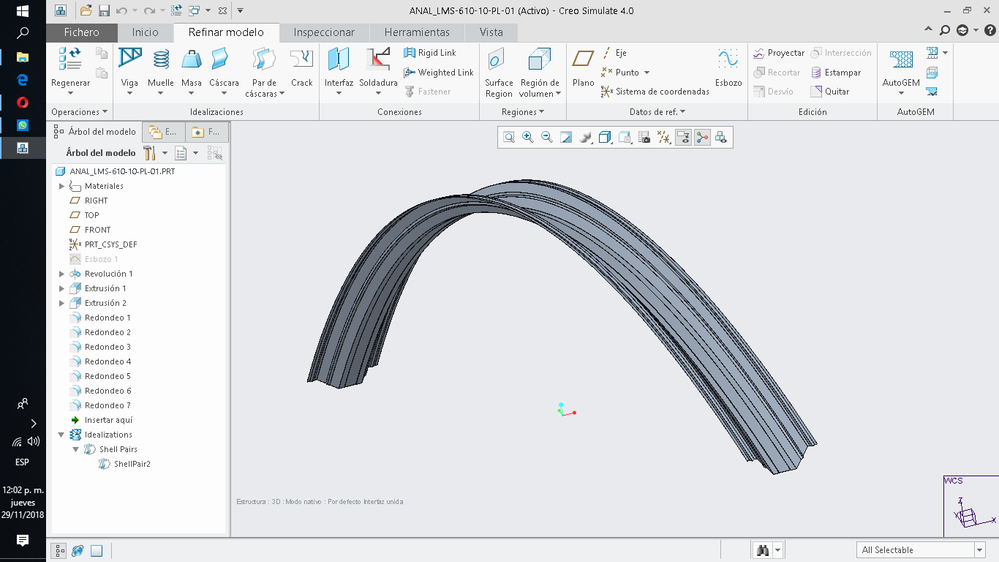

Problem Shell Pair

Hello

1.- When using Detect Shell Pair it does not detect the filletes (R1.0 and R2.0)

The surface is not completed.

What is the problem ???

The whole model is made in PTC CREO 4.0

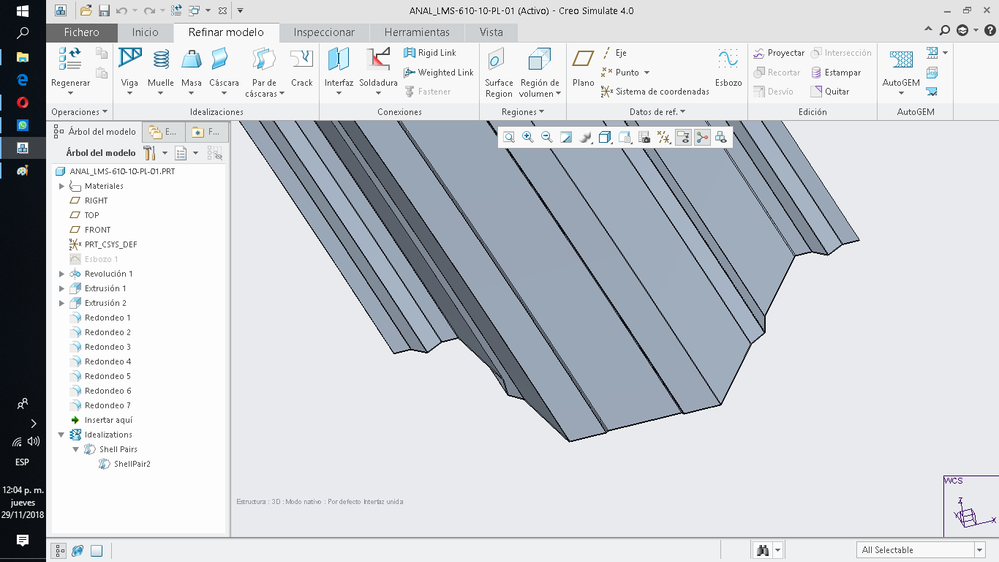

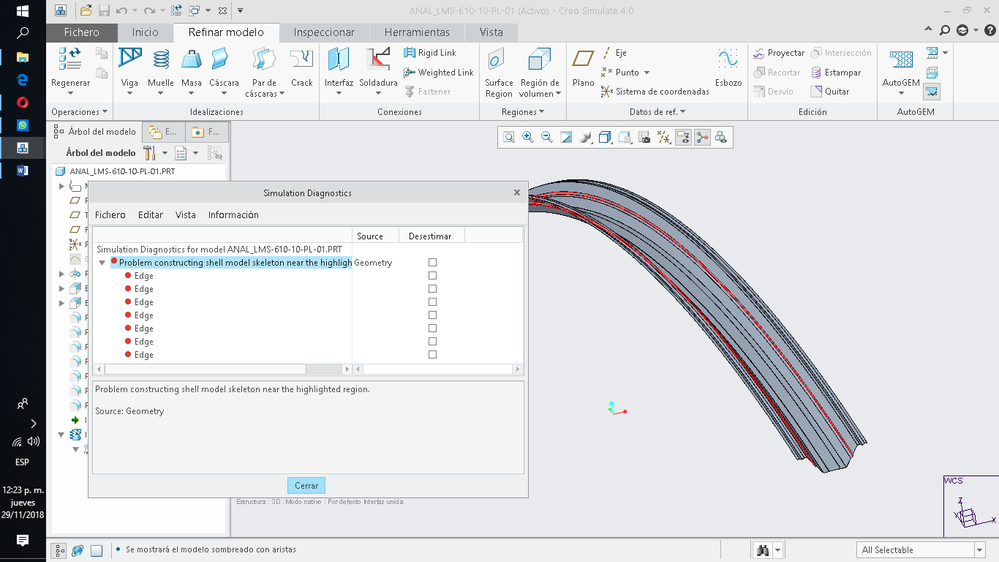

2.- By using Shell Pair manually and with the option to extend adjacent surfaces, the average surface sought is formed.

By using the AUTOGEM Review Geometry, it shows error in the edges

I have adjusted the absolute and relative precision variables, to be able to form those fillets (R1.0 and R2.0).

I assume that some variable needs to be adjusted in order to achieve the mesh of the average surface.

Regards

Carlos Mora L.

Solved! Go to Solution.

- Labels:

-

Simulate

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you very much to all

Unfortunately i had to use Ansys for the analysis.

I am currently modifying an existing Tank so that it has 03 compartments.

Also use PTC CREO SIMULATE but there are singularities that I could not eliminate in the end.

Personally really like PTC CREO.

Maybe i'm lacking in practice in the mesh methods that PTC / CREO uses,

Thank you very much for your help.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The problem is with modelling.

My understanding is that auto-detect only detects thin solids, shelled solids, and thickened quilts. Your rounds are not made by these.

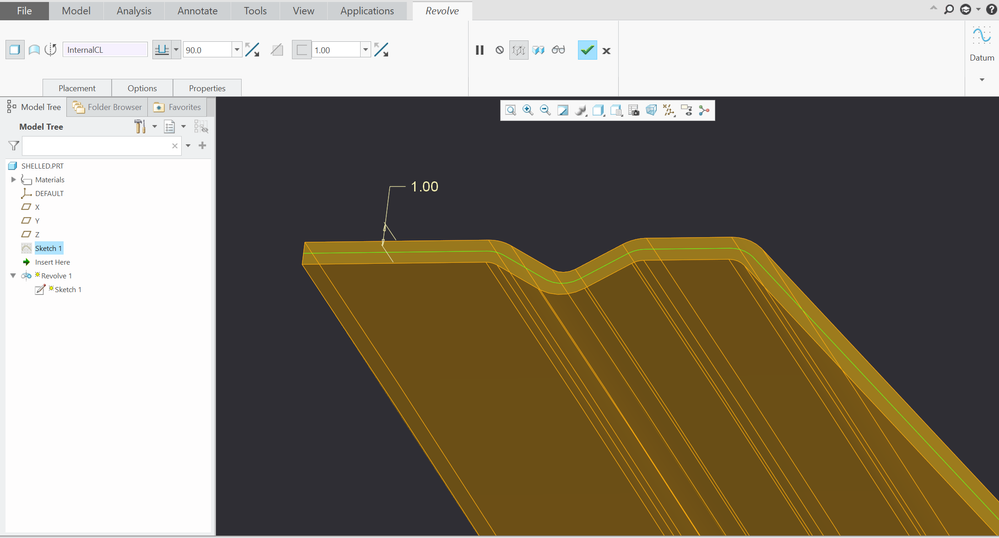

In my opinion a good modelling practice would be to include the fillets in the revolved cross section even if not simulating.

Thin solid

Also useful is [REFINE Model] Review Geom

Consider whether you need to model the small fillets.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello,

I don't think it's a good practice modeling thin radius with shells. The curvature is too high and you have to use solid elements.

I suggest you to insert volume regions "on the radius" in the way you extrude the volume along the length.

I don't remember the right curvature value beyond which you can use shells...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks gfraulini.

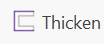

According to this documentation, the curvature is OK but getting close.

Note: Use the midplane surface for the curvature analysis.

This design is curvature 0.667 * thickness 1.0 = 0.667 < 1.5 so it is OK.

According to this the minimum radius would be 0.17 (0.67mm radius at the midplane)

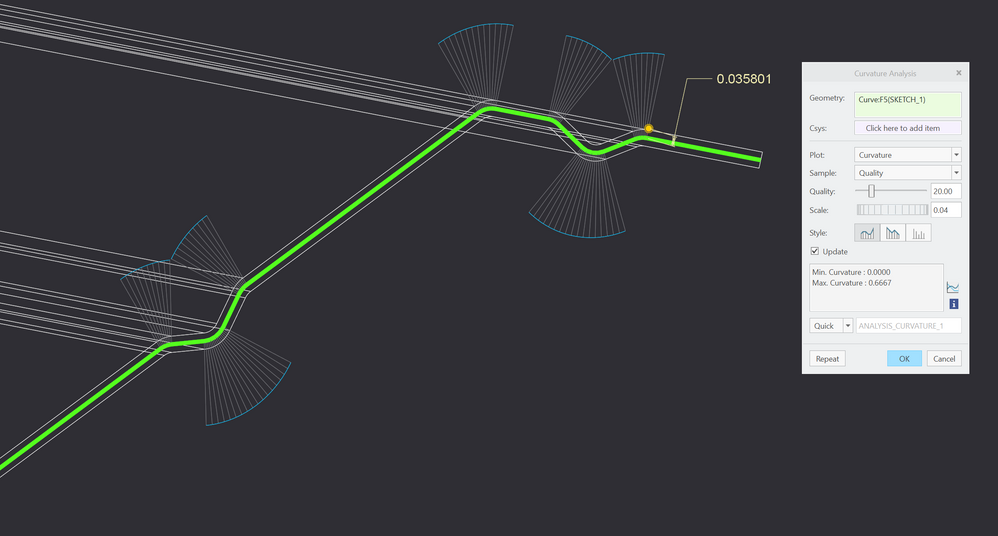

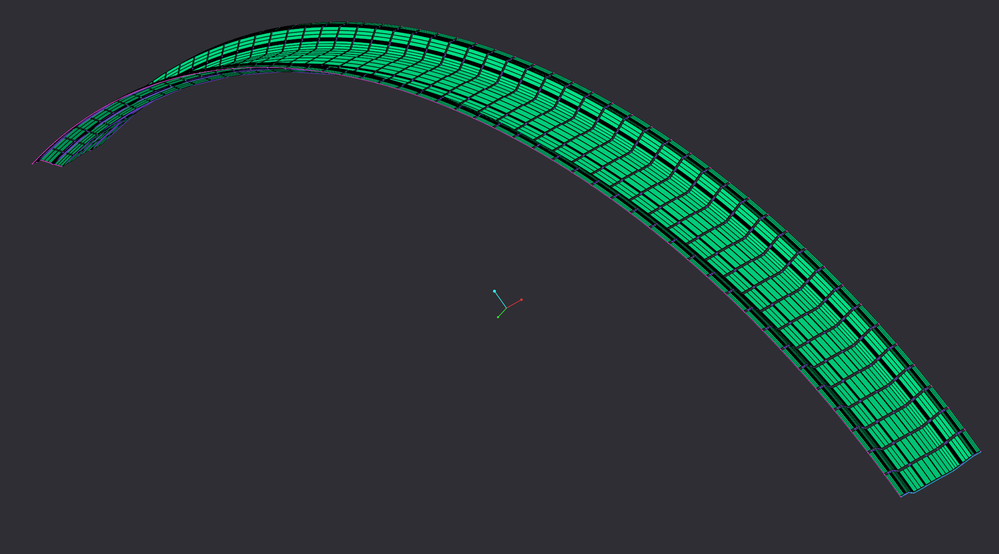

I personally would not use shell pairs, I would use a quilt with a shell property. That would allow a mapped mesh with only quads and a much better mesh and faster simulation. The number of elements and whether I included the small fillets would depend on what I was trying to accomplish. If this ends up as a wheel with spokes on a full model of a bike I would include less details. If I was only interested in deflection/stiffness/mode shapes I would omit the rounds. If I was doing a design sensitivity study I might check the difference with and without rounds and then decide whether to include them for a multiple-run type of study.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Are you able to make a 2D-3D mesh where shell elements touch bricks or wedges which derived from a mapped control?

I tried but it didn't work...

The shells were made at the mid-plane and the mapped control created nodes in the thickness middle so that the two kind of elements can share nodes.

Have you any suggestion?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I can't mesh with mepped elements, but I can with tetra. Why?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

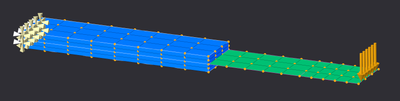

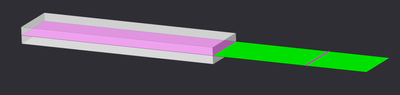

Mapped meshes are tricky. The internal nodes will not connect to neighbor elements even though they appear to match. The nodes/split must be in the geometry and used by the mapping. The thick lines show the separate mappings. I split your model into 4 volume regions as shown. You will need to increase the # elements along the length. 50 worked for me. I used a conic as a middle ground between the radius and the sharp.

Also, here are some visuals for a cantilever beam with mixed mesh, all mapped.

Also it would be a good idea to look at some articles on mapped meshing like mine.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks a lot! I never understand how one can use really this kind of control. What I missed is "The nodes/split must be in the geometry and used by the mapping"

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Glad I could help![]() It took me a while to understand mapped meshes.

It took me a while to understand mapped meshes.

You must understand solid - shell connections. Why they need links. Go Here.

This is a different software but so similar it is worth looking through to get some beginning understanding of being mappable. Creo currently is more difficult, it requires more splitting and handling of transitions.

and this PDF.

For CREO.

And an answer I gave here.

regards,

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you very much to all

Unfortunately i had to use Ansys for the analysis.

I am currently modifying an existing Tank so that it has 03 compartments.

Also use PTC CREO SIMULATE but there are singularities that I could not eliminate in the end.

Personally really like PTC CREO.

Maybe i'm lacking in practice in the mesh methods that PTC / CREO uses,

Thank you very much for your help.