Community Tip - Did you get an answer that solved your problem? Please mark it as an Accepted Solution so others with the same problem can find the answer easily. X

- Community

- Creo+ and Creo Parametric

- Analysis

- Creo Simulate higher than expected

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Creo Simulate higher than expected

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Creo Simulate higher than expected

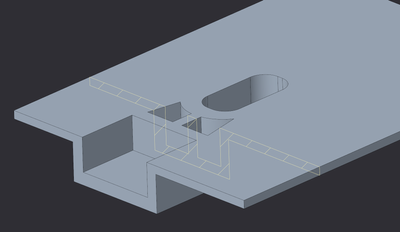

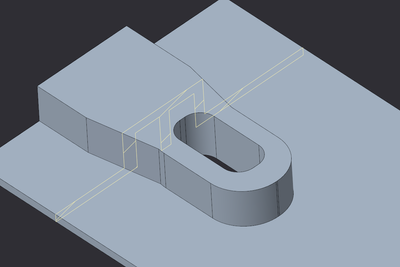

I have a part with older design without ribs. And updated design with ribs.

Under same boundary conditions the maximum stress in older design is 53 MPa

I add ribs in order to give strength to the part and the stress should reduce but its giving higher stress at the rib edges.

I get high stresses at the constraining edge.

I've tried it in other FEA tools and there is no such issue.

Kindly suggest how can I work with singularity like this and why do we have this problem in Creo Simulate and not other FEA tools.

- Labels:

-

Simulate

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This is a problem to be considered by all FEA packages. One of the reasons is because St Venant's principal does not apply near boundary conditions. The reason CREO shows high stress is likely because it is capturing the gradient better than the other packages you tried. Some things to try is reversing the constraints vs. loads, including the real boundary stiffness (mating parts), meshing this area very finely in the other FEA packages to prove the stress is really there, using non-uniform load distributions to fade out the loads. You might be able to limit the P-order and size of elements in this area to "mask" the issue but then you still cannot trust results in this area without other changes to your model. I also suggest that if there are small fillets in the ribs and intersections, you will get more realistic results to at least include those in the areas with higher stress.

Now on your design, I am pretty sure you can confirm that the displacement has been reduced with the added ribbing. (It is stiffer and appears to deflect about half as much) Keep in mind that stress "flows" and that added structure can cause stress to "flow" into the wrong areas. For more on this see this quiz. This quiz. Adding ribs and structure does not always equal lower stress. I think the diagonal ribs create some unique 3d stresses with twist whereas the middle rib is in more pure bending.

I would also consider whether you are required to have all the ribs from one side. I call this section type a "top-hat". It has better bending inertia properties than the original "C" section style you are using. Maybe you do not need the middle rib with this design.

Anyway there is my $.02 based on your question. Thanks for using the PTC community!

EDIT: Also an elasto-plastic analysis will relieve some singularity problems.