Community Tip - Your Friends List is a way to easily have access to the community members that you interact with the most! X

- Community

- Creo+ and Creo Parametric

- Analysis

- Simulation help

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Simulation help

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Simulation help

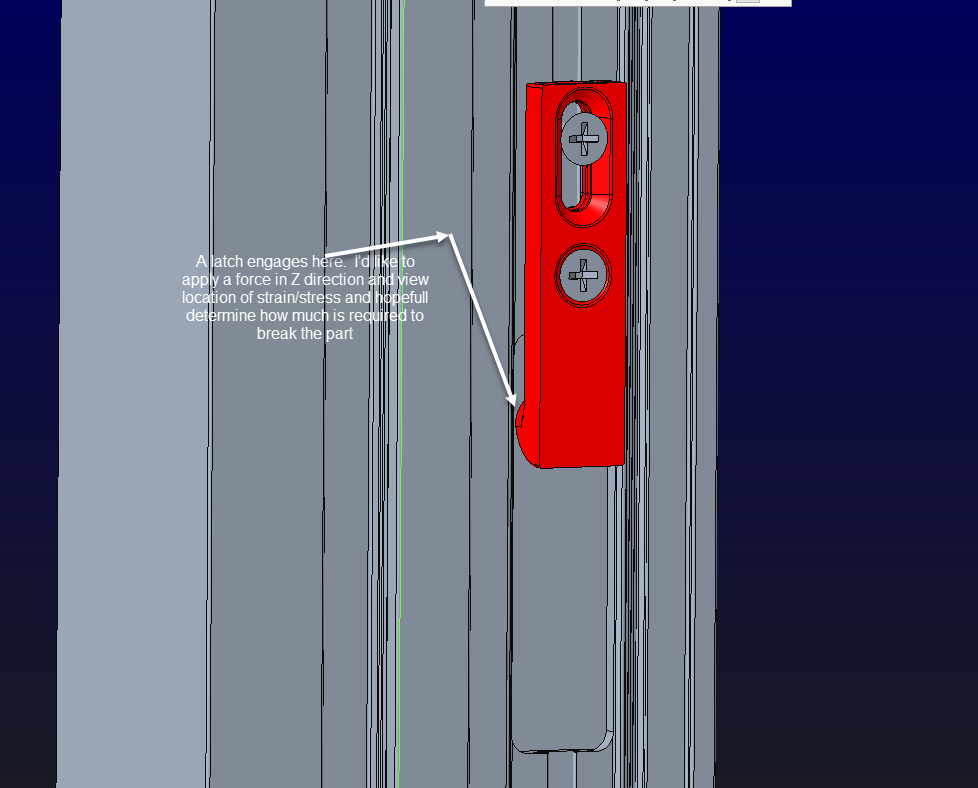

Running Creo 4.0 and I'd like to run a stress/strain or failure analysis on this part. This is my first attempt at a simulations. I have viewed some tutorial videos and PTC courses, but I haven't found a comparable situation yet.

The part bears against a post for 60-70% of the upper length of the part. It is pinned by the 2 screws shown. I know that the failure typically is across the middle of the lower screw but I can't replicate in simulate.

Any help would be appreciated.

Thanks

- Labels:

-

General

- Tags:

- structural

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi,

frankly I struggle to well understand which you've explained.

How does exactly this bit work? Which is the Z's direction? The material?

May you attach the assembly?

Bye

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

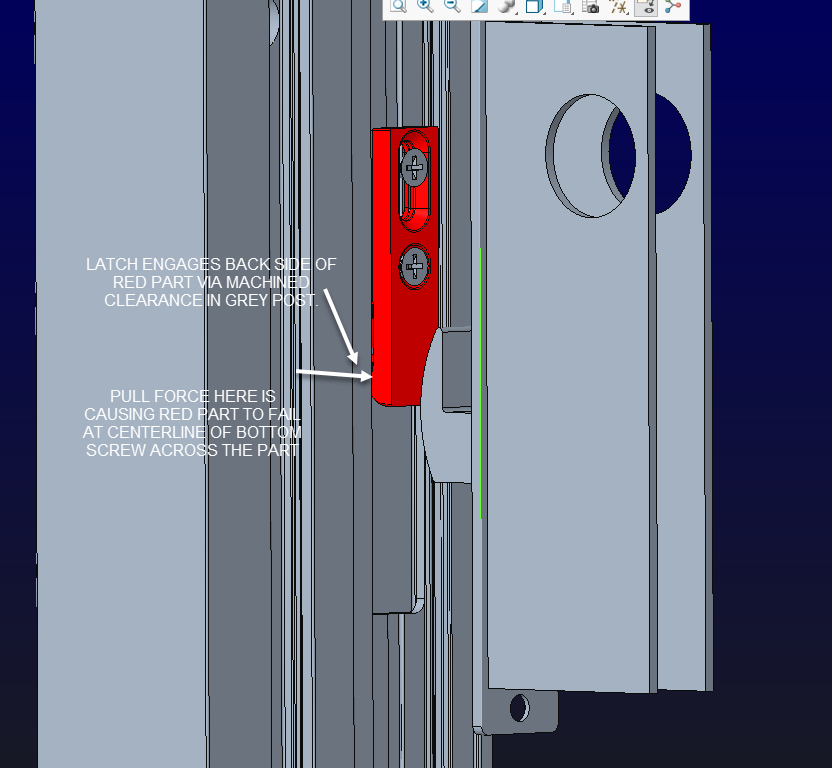

What we're experiencing is failure of the red part by users pulling against the engaged latch. The location that the part fails across the bottom screw. This happens to be where there is the least cross sectional area. Ideally I would like to do a comparative analysis the old part and the part I've revised. I've added material in 3 directions. I expect the part to fail in the same location, but I would like to see how much additional force it requires with the added material. It is cast alum, ADC12.

The only file I was allowed to attach was a .zip

some additional information in picture below

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi,

Are you trying to model only the red latch-plate part? Or the whole assembly with screws, frame, latch-plate?

The red part is simple enough (like a beam) that a rough hand calculation moment diagram and stress should be done.

The only way I can see not getting highest stress near the lower screw is if some bonding is happening to the frame (grey part) that is below the lower screw.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yes the red part only. A hand calc may be the best way. I was hoping I could utilize simulate and learn something new at the same time. Especially on a simple condition like this.

Thanks!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Are you trying to use Live Simulation?

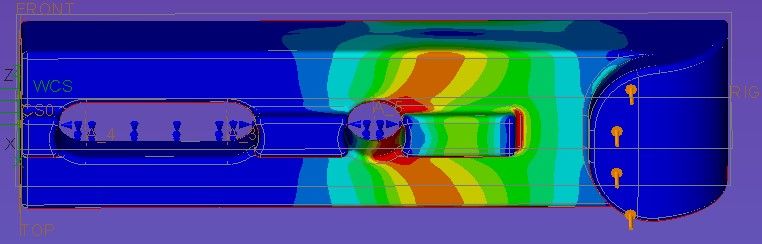

With live simulation, it would be best to run the simulation on just the part. I had to add my own material to it as the values for simulate were not populated. The simulation shows the stress as expected.

There is always more to learn in Creo.