Community Tip - New to the community? Learn how to post a question and get help from PTC and industry experts! X

- Community

- Creo+ and Creo Parametric

- Analysis

- Using structural temperature load

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Using structural temperature load

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Using structural temperature load

I am so frustrated with the results I obtained. I am using Creo 2.0.

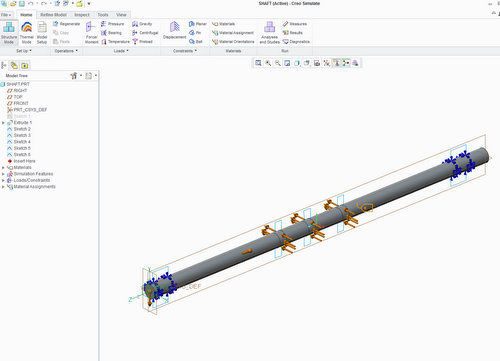

A shaft that was clamp on both end and was loaded in the center of the shaft. If I just ran a static structural analysis. The max Vm is 23K psi and deflection is 0.07. This is the answer that I expected.

But then I need to know what's the change in temperature will do to this result...so I use the strutural temperature load under structure mode and set the temp of entity to 1400 F and reference to 72 F temp. After I ran the strutural analysis. The Vm value went crazy and in the range of 6 millions but the deflection at 0.11 in. Do I approach this problem correctly? Please help

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Labels:

-

Simulate

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You state that your results seem right after applying your bending load, but the results go wrong after applying the thermal load. So I would recommend you check the value of the coefficient of thermal expansion for the material you are using-both for unit consistency and order of magnitude. I roughly calculated that for steel you would have a stress build up due to the thermal expansion of about 97 ksi. So you would have a maximum stress of roughly 120 ksi (23 ksi from bending + 97 ksi) assuming linear superposition and shaft is constrained fully in longitudinal direction. So I agree, your results for stress do seem high at 6 million psi. You may also want to check for stress concentrations at the clamps. You may want to check the vm stress results at the midpoint of the beam on the compression side to see if they are closer to what you expect.