Community Tip - Visit the PTCooler (the community lounge) to get to know your fellow community members and check out some of Dale's Friday Humor posts! X

- Community

- Creo+ and Creo Parametric

- Manufacturing (CAM)

- Re: Trajectory Milling

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Trajectory Milling

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Trajectory Milling

Had some free time to work on this today. Source link

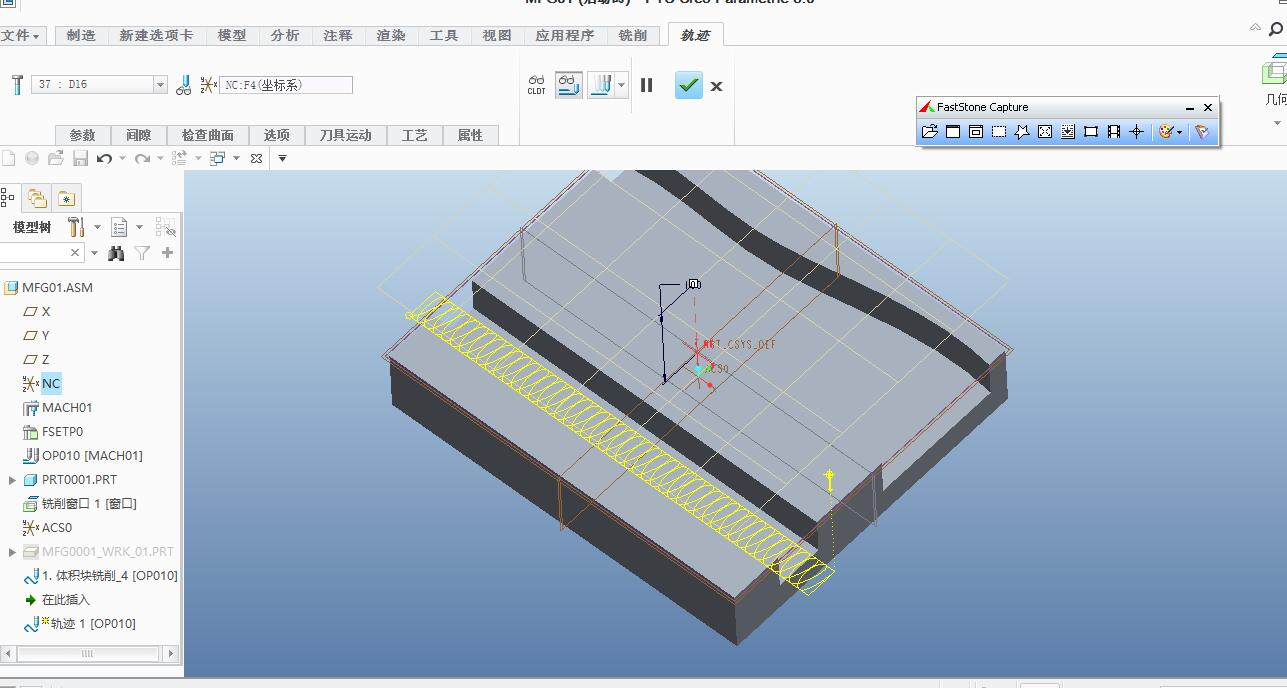

I created a curve by equation and used that to drive a trajectory milling sequence for some long slots I needed to mill.

here is the equation I used to create this curve.

/* ENTER TOOL STEP OVER

SO = 0.05

/* EMPIRICAL VALUE TO CORRECT SHAPE ERROR

SF = 0.0175

/* ENTER PROFILE ALLOWANCE (STOCK)

PA = 0.005

/* ENTER TOOL CUTTER DIAMETER

CD = .3937

/* ENTER SLOT WIDTH

SW = 0.811977

/* ENTER NUMBER OF REVOLUTIONS

N = 100

A = ( ( SO * SF ) / 3.141592654 ) / 2

B = ( ( SW - ( 2 * PA ) ) - CD ) / 2

x = ( A * ( t * N * 360 )) - ( B * sin ( t * N * 360 ) )

y = ( B * cos ( t * N * 360 ))

z = 0

I don't understand what the shape error value is about but it seems to work for this application. Just thought i should share this with everyone in case they wanted to use it or improve it ![]()

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Labels:

-

General

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Nick,

Nice looking tool path !

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you ![]()

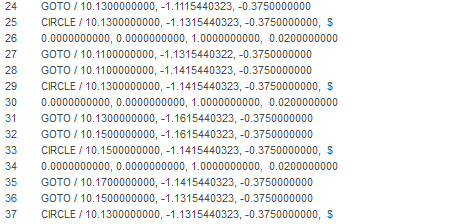

I'm finding that the cl data and g-code is all points so now am looking into arc fitting but not sure if this is a wise move.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Interesting application.

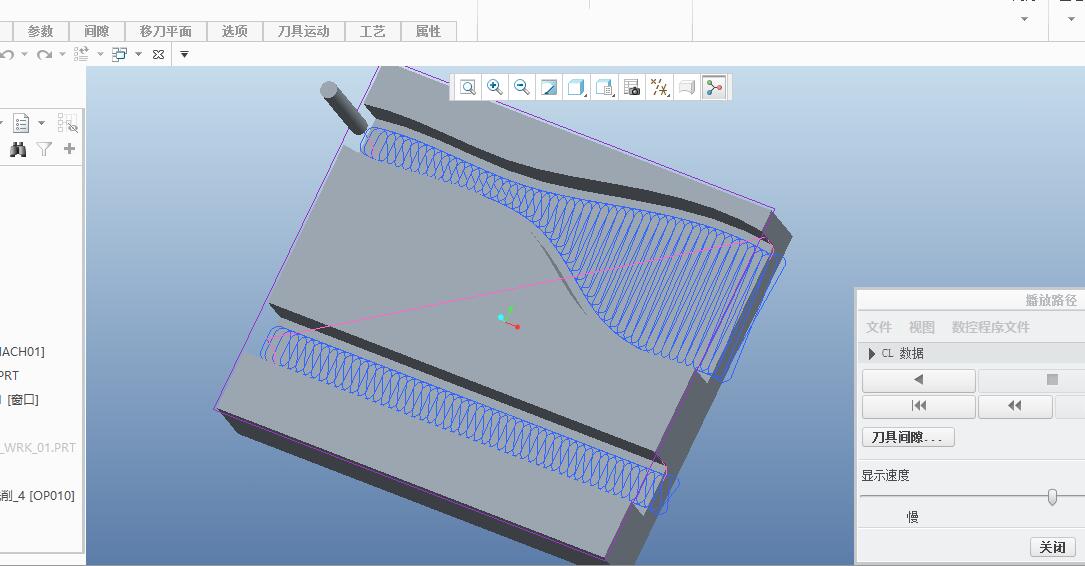

If you are using creo3you can do something similar using volume-mill and the cl data isn't all pts. This would allow you to control tool selection and parameter adjustment normally. You can also do slots that aren't straight.

Josh

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

oooh i like the look of that cl data but volumill is extra $ correct?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Don't know, sorry.

Josh

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Joshua - was that curve created using a "Volume Milling" sequence in Creo (constant load?), or using the third-party "VoluMill" addon from Celerative?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Creo "Volume Milling" with constant load, need creo3 and there are required parameter settings to keep the tool down.

Josh

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Joshua - Thanks for the response. The toolpath looks promising. I believe I read an earlier thread that detailed the parameters required.

We're still Creo2, but moving up to the next release of Windchill this weekend, so we're getting closer to new releases of Creo.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I haven't been doing any programming for a couple years now, but was reading through the forum to see what's new. I used a similar technique as Nick and also didn't have an accurate solution to the step-over value - I just tweaked the STEP value to get what I needed. I didn't use it frequently enough to invest time resolving the step over issue.

Throchoidal milling curve: I used a CSYS to anchor the start of the curve orientation of the path - the default vector for the path is Y+. I could also juggle the X/Y calculations to control the vector and climb/conventional cutting condition as shown in the example.

/*-------------------------------------------------------------------

/*

/* RAD = radius of path (slot_radius - cutter_radius)

/* STEP = determines "step-over", **STILL GUESSING ON VALUE**

/* DIST = total travel distance

/* DEGS = CALCULATED, DEGREES: distance_required/step*2*360

/* ------- FORMAT -------

/* x = (STEP-RAD*cos(t*DEGS))-STEP

/* y = STEP*((t*DEGS*STEP*3.14159)/360) - RAD*sin(t*DEGS)

/* z = 0.

/*

/* -- OPTIONAL -- ADD THE FOLLOWING PARAMETERS TO THE ASSEMBLY --

/* NR: RAD (REAL NUMBER, 0.0)

/* NR: STEP (REAL NUMBER, 0.0)

/* NR: DIST (REAL NUMBER, 0.0)

/* NR: DEGS (REAL NUMBER, 0.0)

/*

/*

/*------------------------------------------------------------------

/* -- IN SAMPLE BELOW X/Y REVERSED FOR X+ ADVANCING CUTS

/* -- IN SAMPLE BELOW Y IS REVERSED FOR CLIMB: "-(STEP" & "+STEP"

RAD=.03

STEP=.095

DIST=2.

DEGS=(DIST/STEP)*720

Y = -(STEP-RAD*COS(t*DEGS))+STEP

X = STEP*((t*DEGS*STEP*3.14159)/360) - RAD*sin(t*DEGS)

z = 0.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

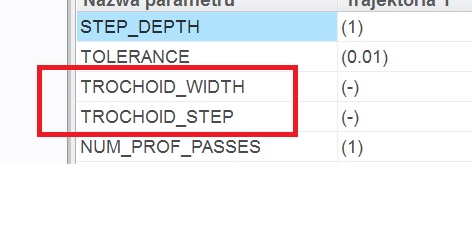

Set hidden option in your config.pro

trochoid_milling yes

Then in your parameters of 3 axisTrajectory miling appears 2 additional parameters:

TROCHOID_WIDTH and TROCHOID_STEP

and then you can use it.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello Tomasz,

I have the question.

How the Trajectory sequence should be defined to be able to create such trochoidal milling ?

Thank you.

Rostislav

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You can use Trajectory milling with hidden parameters. First you must add TROCHOID_MILLING parameter to your config.pro and set it to YES. Then in Trajectory milling apears 2 additional parameters TROCHOID_WIDTH and TROCHOID_STEP. If you set its, your path will be trochoidal. In this case you should be carrefur because tool gauges a milling part. You must measuring slot and use right parameters. This functionality will be officially in creo 4.0 and maybe it will be works better.

Above chuyxq chu used propably Volume milling or Raughing with Constant Load value in Scan Type parameter. Additional uesed MIN_RETRACT_DIST. Value of this parameter should be large for example max length of milling part. Then tool should stay on milling surface. If you set any small value of LIFT_TOOL_CLEARANCE, you tool lifts above part.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello Tomasz,

From which build code can you set this hidden config.pro setting? At the moment i am working with Creo 3.0 M070. I don't want to update to the latest with all the failures that's going on with Module works at moment.

Kind regards,

Paul

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello

It should works since Creo Elements/Pro 5.0.