- Community

- IoT & Connectivity

- Mfg Solutions & Apps

- Re: Why OEE is zero?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Why OEE is zero?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Why OEE is zero?

Hi Experts,

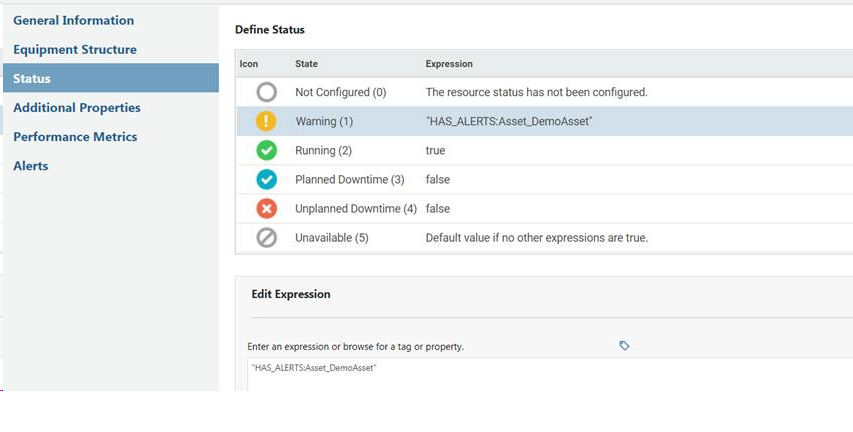

I configured my demo asset as the following

My KPI Calculation Period is 1 minute.

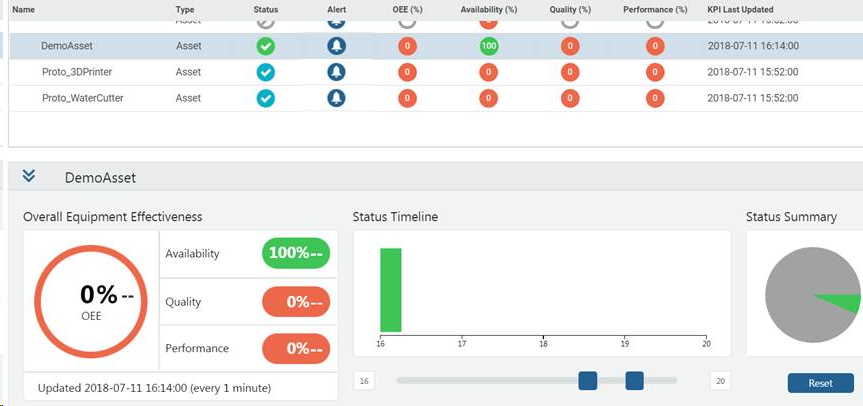

But my OEE,Quality and Performance are all 0

Can anybody tell me why OEE is always 0? I don't understand what's the problem.

Thanks & Best Regards

Tom

Solved! Go to Solution.

- Labels:

-

Troubleshooting

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

That's a good question, and has to do with how we handle rollover. Because counters don't have infinite space, and may be reset at one time or another, we save a valuestream of the current good count and bad count. When the counter drops below the previous number, we assume it rolled back to zero and then continued counting up.

Essentially what's happening is every time it drops down, this happens:

Drops from 800 -> 799

System thinks made 800 before, reset to zero, and then made 799

799 parts in the last X period of time -> feed it into the calculation.

Does that make sense?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Greetings @weli,

OEE is calculated based on Availability, Quality and Performance

The quality and performance are calculated as :

Quality = Good Count / Total Count

Performance = (Total Count / Run Time) / Ideal Run Rate

From the screenshot I can see that you manually entered Good Count and Total Count in Parameters for Performance Calculations. Can you browse tags for Good Count and Total Count from the Kepserver for this asset instead of providing manual values.

You can refer https://community.ptc.com/t5/Manufacturing-Apps/0-Performance-at-times/m-p/520717 community thread for detailed information on OEE and other KPI calculations.

Thanks,

Himanshu

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Himanshu,

Thanks for your help.

Before I stared this topic, I already read the post you mentioned, and I read the document of how to calculate OEE, but I still don't understand why my OEE is zero. my understanding is:

my good count is 1,and total count is 1,so my quality should be 100%,

Performance=(Total Count / Run Time) / Ideal Run Rate , so at least my performance should not be 0,and since

OEE = Availability * Performance * Quality, my OEE should never be 0.

Thanks & Best Regards

Tom

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

In run time your total count will variate. The total count in this time will be the difference of the old total count and the new total count. If there is no differentiate it will no calculate. At last this is the way that I view it.

About quality I am not sure, but maybe the same things go for it, it has to be a value that changes on time.

Please someone correct me if I am wrong.

You can Override this calculations also to best fit your tags and the way that the company calculates OEE.

Hope it helps,

Vinicius Xavier.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks for help. But why should total count variate? The OEE is zero because of the current good count and bad count are same as last time? If that is true, let's say a very "stable" device which good count is always 100, and bad count is always 10, so OEE should always be 0? That doesn't make sense to me.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I don't know, the way I view it, your factory is always producing, so the good and bad count is always increasing, as the total count.

For example, at 10 am you have produced 100 products, 98 good count.

At 11 you have 135 and 130 good count.

If your ideal was 40 per hour. You have as performance (135-100)/40 = 87,5%, and for quality (32/35) = 91,42%

That way, if you produced nothing in the last hour, you don't have how to made the calculations.

I don't know if this is really the way that calculations are made, but how I understand it. Can be different. I am just trying to share my view with you, is not a validated answer.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

By definition, the good count and the bad count are designed to change - to increase, and roll over to decrease. Imagine you're in a factory, and at 8:00 AM, you've produced 100 good product and 100 bad product. At 8:01, your counter still reads 100 good and 100 bad parts - by definition, you haven't created any parts (there is no change), and therefore your performance of the machines is zero, math shown below.

The number of parts produced (0 products)

divided by the time (1 minute)

divided by how many parts you should have produced (5 products/minute)

For a process system, with flow rates for example, this calculation needs to change - but the calculation will change significantly, as quality inspection will be done out of line. This would require a customization to the OEE calculation - you can find the details in the customization guide of the manufacturing apps.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks.

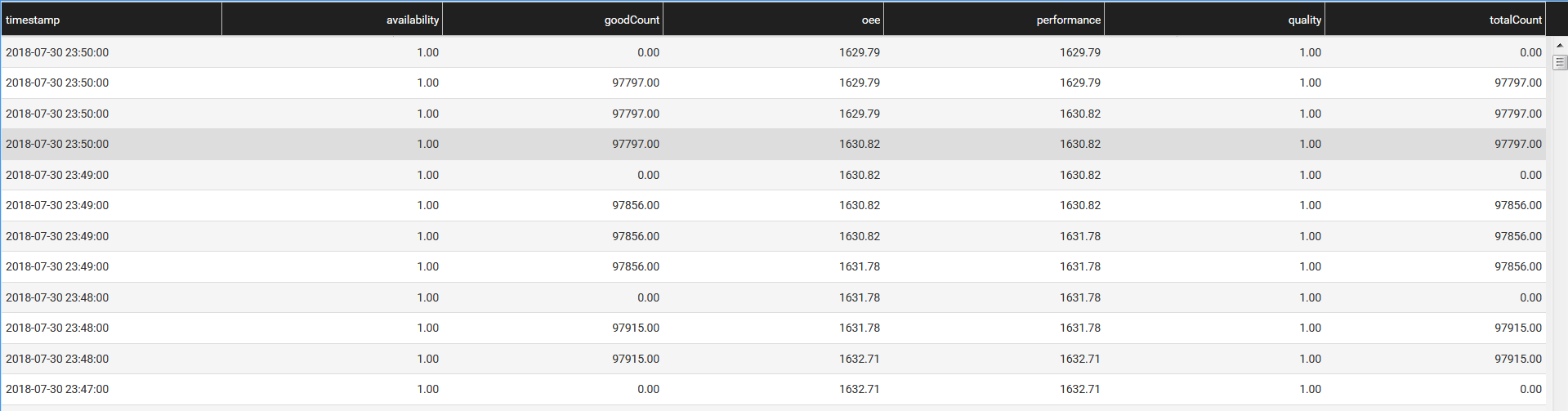

That does make sense. I created a simulated data in KepServer

RAMP (1000, 1.000000, 100000.000000, 1.000000), means from one to ten thousands,add 1 every second, configured my device, both good count and total count as this data source. and ideal run rate is 60, and my KPI calulation period is 1minute.

The OEE seems good.

Since my good count will add 1 per second,so in one minute good count is 58,59,or 60, seems correct. But some rows, the value of good count is zero, I don't know why.

After that, I changed data source in KepSever from RAMP (1000, 1.000000, 100000.000000, 1.000000) to

RAMP (1000, 1.000000, 100000.000000, -1.000000), which means decrease the value per one second. My OEE is 999%.

I guess when calculate KPI, if new total count is smaller than the old one, APP will just use the new value, if the new value is equal to the old value, performance is zero,oee is zero, if the new value is bigger than the old value, will count the increased value and calculate KPI.

If I am wrong,pls correct my.

Thanks

Tom

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

That's a good question, and has to do with how we handle rollover. Because counters don't have infinite space, and may be reset at one time or another, we save a valuestream of the current good count and bad count. When the counter drops below the previous number, we assume it rolled back to zero and then continued counting up.

Essentially what's happening is every time it drops down, this happens:

Drops from 800 -> 799

System thinks made 800 before, reset to zero, and then made 799

799 parts in the last X period of time -> feed it into the calculation.

Does that make sense?