Community Tip - You can subscribe to a forum, label or individual post and receive email notifications when someone posts a new topic or reply. Learn more! X

- Community

- PLM

- Windchill Discussions

- Re: Negative Issue Parts in BOM (Windchill 10.2)?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Negative Issue Parts in BOM (Windchill 10.2)?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Negative Issue Parts in BOM (Windchill 10.2)?

I have a module that contains a control panel, so an assembly inside another assembly.

- Module

- Control Panel

- (with part I want to negative issue)

- Control Panel

Is there a way to 'take away' a part in a BOM?

- Module

- Existing Part I want to negative issue

- Control Panel

- Original Part

The control panel is purchased with the part I want to remove, so I don't want to create two different control panels for a small part that we will take care of ourselves. I tried tying in a (-1) for the quantity, but Windchill doesn't allow negative numbers. Does anyone know of a way I can handle this?

I'm using Windchill 10.2 and Creo 2.0

- Labels:

-

BOM_Platform Mgmt

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Where are you trying to make this change?

I assume the Part Structure/BOM is CAD-driven, right?

If you remove the part from the CAD assembly, check-in and rebuild the WTParts does it remove the part from under Control Panel?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I can't speak to Amanda Steinke's use case but I have run into this before as well. Product definition is not always start with low level parts and build up... sometimes it's start with an off-the-shelf product (probably something that you have purchased) and remove some stuff, add other stuff thereby transforming it into a new solution/deliverable. For these use cases, IMO what comes off is as important as what goes on. In order to validate accuracy things need to be rationalized... did all of my add items get consumed and do I have all of the deduct items remaining?

To resolve this I have previously used a custom unit of "dea" (for deduct each) to represent the negative. Then 1 dea = -1 ea, but this was representative only with no systematic propagation of BoM information to an external system such as ERP/MRP. The same challenge holds for fractional or decimal units. I won't say all ERP/MRP systems do this, but some that I have seen allow for both negative and partial quantities associated with each. It would be nice to be able to do the same in Windchill so that unit interpretation did not need to be applied at data propagation.

As far as CAD-driven Part Structures goes, that's a whole different can of worms. CAD allows for flexible parts and bulk items, both of which may be best expressed in non-each quantities, yet Windchill seems to only see CAD in unit (each) terms. The deduct use case might apply if you were using a process assembly and suppressing a component in a later step - I have not tried this (even to see if Creo allows step specific suppression and if so does application behavior align with design intent). It would be ideal if it did as it would allow for complete and robust definition.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I have seen this need as well, for similar reasons as Keir Pritchard outlined.

For example, a military vehicle is being converted from a base configuration to a custom one. Equipment falls into several categories - Remove and discard; remove and reinstall at a later assembly step; leave as-is; remove, modify, and reinstall. Sometimes the reinstalls are with the additional complication that the item is reinstalled in a different location, so just rendering them invisible for a few assembly levels is not sufficient.

Typically simplified reps and assembling duplicate items is used to patch over the graphical appearance of the assemblies, but there's no good automated way to validate the logic.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I have another use case for negative quantity in a BOM.

We have a few machining operations that generate wastes which are then reused (sprue of plastic material injected into a mold or scraps of ferrous material).

As you can understand, when we use these recycled materials in a BOM it's not necessary to buy it again.

In these cases we use negative quantity to consume recycled materials.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

We've got excatly this use case ...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I have this requirements too. Need to specify scrap quantity in MBOM so that it can go as negative quantity in Oracle ERP. Liked the idea from krptichard but then we may not be able to specify the unit for the Scrap amount. Else create multiple negative units such as "dea" , "dkg", "dltr" etc.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

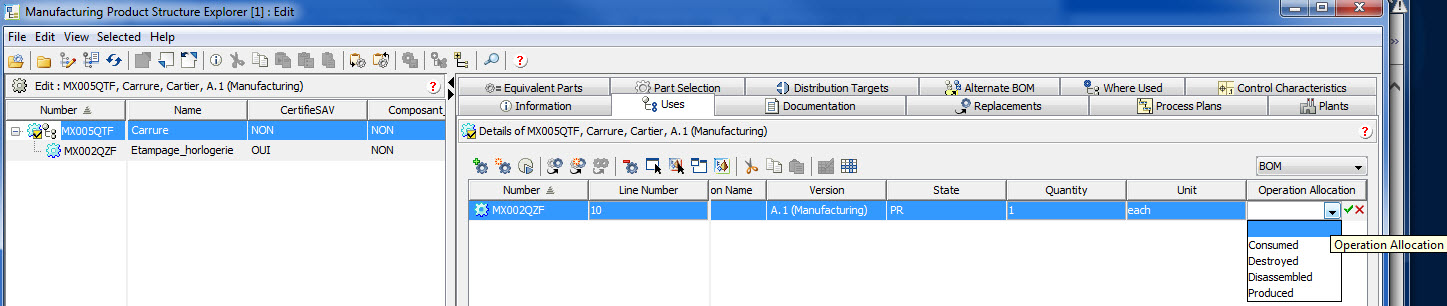

If you have MPMLink, there's an attribute on the BOM usage link "operation allocation" , where you can choose "disasembled or, produced" ...

in that case, Windchill, and notably ESI will set the quantity as negative in the release message to ERP ....

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Is anyone actually using this functionality? When I try this, the ESI response is not rendering the parts or BOM and the operation to part links are all positive quantities. I'll put in a ticket in the meantime, I'm just wondering if I missed some configuration point.

Thanks,

Casey

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

any update for this case?

I have the same issue.

thanks