Community Tip - Learn all about PTC Community Badges. Engage with PTC and see how many you can earn! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- File size is so large

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

File size is so large

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

File size is so large

Dear Folks

I have create round plate with 220 holes, a single file size is 170 MB. May i know why?

I have used a revolve tool, and hole with round tool then pattern.

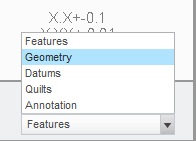

I have attaced screen shot, kindly view it. and why the file size is increase

For Example:

Regards

Viswanathan.K

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The part file maintains a graphics copy of the geometry being displayed. The graphic quality settings will affect the size of this graphic model.

I highly recommend you add the following to all your config.pro files:

save_model_display wireframe

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Visawanathan,

Edit definition on the pattern and make it identical. That will dramatically improve your regen time.

Best Regards,

Karl Krahmer

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It's the geometry of the rounds that is doing it.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Pattern Geometry is only a definition and therefore is not a large data block in the file. The actual polygon count in the lightweight model maintained in part and assembly files is what is taking up most of the space. If the graphics settings in the options are set to high quality, the polygons are smaller and therefore more of them. By default, the system stores the parts as shaded representations. Wireframe is a lot more efficient for storage.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This is exactly why PTC needs to seriously look at their lightweight modeling strategy for previews and fast viewing. I hate that this information is stored in the file...I feel the entire enterprise of Windchill and Creo should use the lightweight ol(Creo View) file generated from the windchill publisher for previews and a revamped strategy for looking at lightweight reps in Creo Parametric. It's ridiculous how many lightweight image formats and embedded information is hurting performance and unnecessarily duplicating information which makes managing images in the enterprise very difficult...you have thumbnails in windchill, previews within Creo Parametric, the structure visualization tab in Windchill and Creo View. For the companies going to Creo View as the large assembly viewer, we want single source of the truth!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The .JT format is suppose to be the CAD solution for lightweight graphics and works quite well when implemented properly. PTC has chosen to manage files from within the master (except drawing [?]) and therefore, all the overhead is stored into that one file. As to how it all actually works and how one can manage it seems to be a a formula stored in a secret lab somewhere in Roswell, NM because we sure are not privy to what is -really- going on in that alien's head.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Antonius, there always has to be somebody on the opposite side of the fence! ![]() Either way, a solution to enable one of these two formats needs to be made available. Your point is part of my frustration...one big company is strongholding PTC to use JT and they are not using Windchill. While another big company in Windchill has invested a lot in switching over to .ol format because they found out that loading models is twice as fast as JT and the models are more accurately placed in space when opened in the Creo View. As a Windchill user, you can understand which side of the fence I'm on. My perception is that the Creo team talks more to the big company than the Windchill team. Probably not true, but sure does seem that way in some cases....

Either way, a solution to enable one of these two formats needs to be made available. Your point is part of my frustration...one big company is strongholding PTC to use JT and they are not using Windchill. While another big company in Windchill has invested a lot in switching over to .ol format because they found out that loading models is twice as fast as JT and the models are more accurately placed in space when opened in the Creo View. As a Windchill user, you can understand which side of the fence I'm on. My perception is that the Creo team talks more to the big company than the Windchill team. Probably not true, but sure does seem that way in some cases....

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

......I guess size DOES matter..... ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Take a look at this response in an different thread:

http://communities.ptc.com/message/206649#206649

There is a PDF attached that shows the impact different settings have on file size.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

On the plate create a hole and round features.

then  go with seed & boundary option

go with seed & boundary option

make a copy of the surfaces. then solidify the surface. then pattern the copied surface and then pattern the solidify.

this will reduce your file size by 60% and regeneration time by 70%.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Don't bet on that, Manoja. Even though the entity count may be down, the geometry copy still calculates intersections. Have a look at the discussion linked below where both regen times and file size are really red herrings when it comes to knowing what is going on behind the scene.

Feature Failure with Repeating Patterns

As a matter of fact, I find the copy geometry patterns tend to fail more often than regular patterns.

Although I agree that your statement -should- be correct, PTC's implementation of a "simple copy" is not simple after all.