Community Tip - Visit the PTCooler (the community lounge) to get to know your fellow community members and check out some of Dale's Friday Humor posts! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Advanced Parametric BOM

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Advanced Parametric BOM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Advanced Parametric BOM

Hello all,

Looking for a specific answer here with an advanced parametric BOM we use at my work. We use a regular standard repeat region table style that just pulls parameters from the part files that gets entered into our Windchill (common name, part number, quantity, cage code, etc). Now every once in a while we use a multi level bom when we have multiple assemblies that use similar parts and end up on the same drawing. My problem is I want the BOM to report the quantity of parts that repeat through many or all of the separate assemblies only once.

Example:

My drawing is going to show 6 assemblies that have a plate in each assembly that is unique in fashion but all use the same 10-32 screw with a quantity of 4. In the bom it shows quantity 4 of the 10-32 screws in 6 different locations on the BOM because you have 6 repeat regions in this instance. I want the BOM to only have a single line of the 10-32 screws with a reported quanity across the row and not 6 quantity reports across each repeat region.

Is the repeat region not 'smart enough' to be able to 'talk' to other repeat regions?

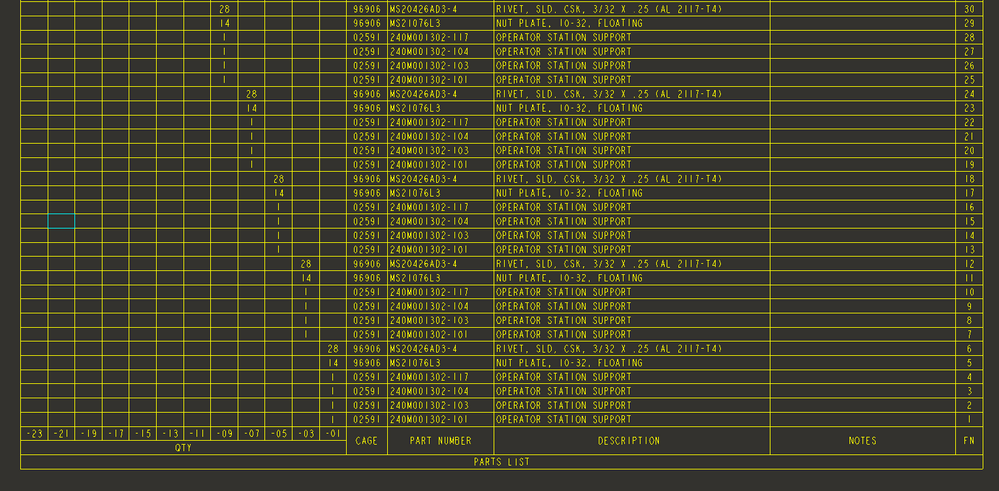

Here is a screen capture of the current bom i am fighting. As you can see I have lots of assemblies and I want it to remain parametric and not have them repeat.

Thanks

- Labels:

-

Assembly Design

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

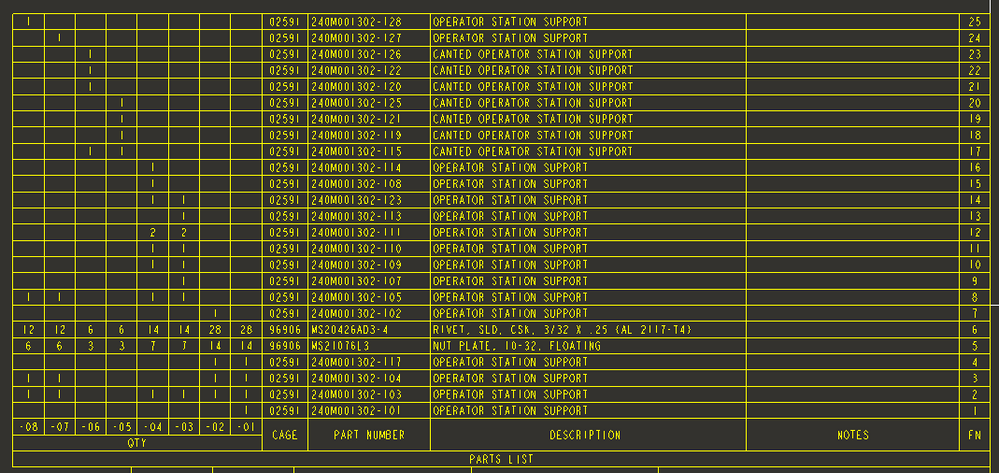

I finished combining all of the line items as needed. Here is what my table needed to look like, but has lost about all of its parametric qualities except for the first assembly (-01).