Community Tip - Need to share some code when posting a question or reply? Make sure to use the "Insert code sample" menu option. Learn more! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Any Toroidal Bend experts out there?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Any Toroidal Bend experts out there?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Any Toroidal Bend experts out there?

I'm looking for better explanations of the options in Toroidal Bends.

This seems like a very powerful command but the available text is enigmatic at best.

Some real world examples of how you use this would be appreciated.

From the help files:

About the Toroidal Bend User Interface

Toroidal Bend to open the Toroidal Bend tab.

Toroidal Bend to open the Toroidal Bend tab.

| • |  Profile Section collector—Displays an internal sketch or an external section to determine the profile section. The profile section must contain a rotatable geometry coordinate system to indicate the location of the neutral plane. For internal profile sections, you cannot exit Sketcher and continue without creating a valid coordinate system. Profile Section collector—Displays an internal sketch or an external section to determine the profile section. The profile section must contain a rotatable geometry coordinate system to indicate the location of the neutral plane. For internal profile sections, you cannot exit Sketcher and continue without creating a valid coordinate system. |

| • | Bend Radius list—Specifies the bend radius of the neutral plane in one of three ways:

|

| • | Bend options collector—When you select a bend radius option, one of the following data collectors appears: |

| ○ | Bend Radius—Sets the value of the bend radius. |

| ○ | Bend Axis—Sets an the axis to bend around. |

| ○ | Bounding Planes—Sets two planes to define the geometry and the length of the bend. |

| • | References

|

| ◆ | Profile Section Unlink—Edits the selected profile section sketch. |

|

| ◆ | Normals Reference Section collector—Displays an external sketch as the reference for the normal vector direction of the toroidal bend. When a normals reference section is applied, it references the profile section. Place it as close to the profile section as possible. Avoid the area where the profile section is not tangent or has high curvature. The normals reference section must be long enough for all points in the profile section to have a projection on it. Preferably the two sections either coincide where the curvature is low, or one is an offset of the other. There are two ways to create this dependency:

|

| ? | Normals Reference Section Unlink—Activates Sketcher to edit the normals reference section sketch. |

|

|

| • | Options

|

You can apply the nonstandard options only if the curves to bend lie on the neutral plane.

| • | Properties

|

The Bend Radius handle displays and modifies the bend radius dimensions when the Bend Radius option is selected. Enter a new value into the input panel.

Right-click the graphics window to access shortcut menu commands.

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Labels:

-

General

- Tags:

- toriodal_bend

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Interesting, the 1st video is using toroidal bend where a spinal bend would work.

The second video is less clear as to what is being bent in the X direction and is also a spinal bend application. Not sure if there would be a difference.

I was more interested in the subtleties of the command like normals collector and options. There is precious little information (that I can comprehend, anyway) on what these things do and how to properly use them.

The 1st thing I learned is that the section's coordinate system has to face the right way (Y toward the axis).

As an aside, anyone else find that the Warp tool is really bad about goining ends when you think you have a full 360 degree bend?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I have not used this command myself much. This command is typically used to model a Tyre of an automobile, where in you have a bend in both the directions. I never understood how the command works till I studied the videos again and again and tried it out myself.

Here is another link from PTC's Learning Exchange. It does not have an audio, but atleast instructions displayed on the screen.

http://learningexchange.ptc.com/tutorial/2314/create-toroidal-bend-feature

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yep, that is the video that follow the help pages with the same model. It provided enough information to use the command successfully.

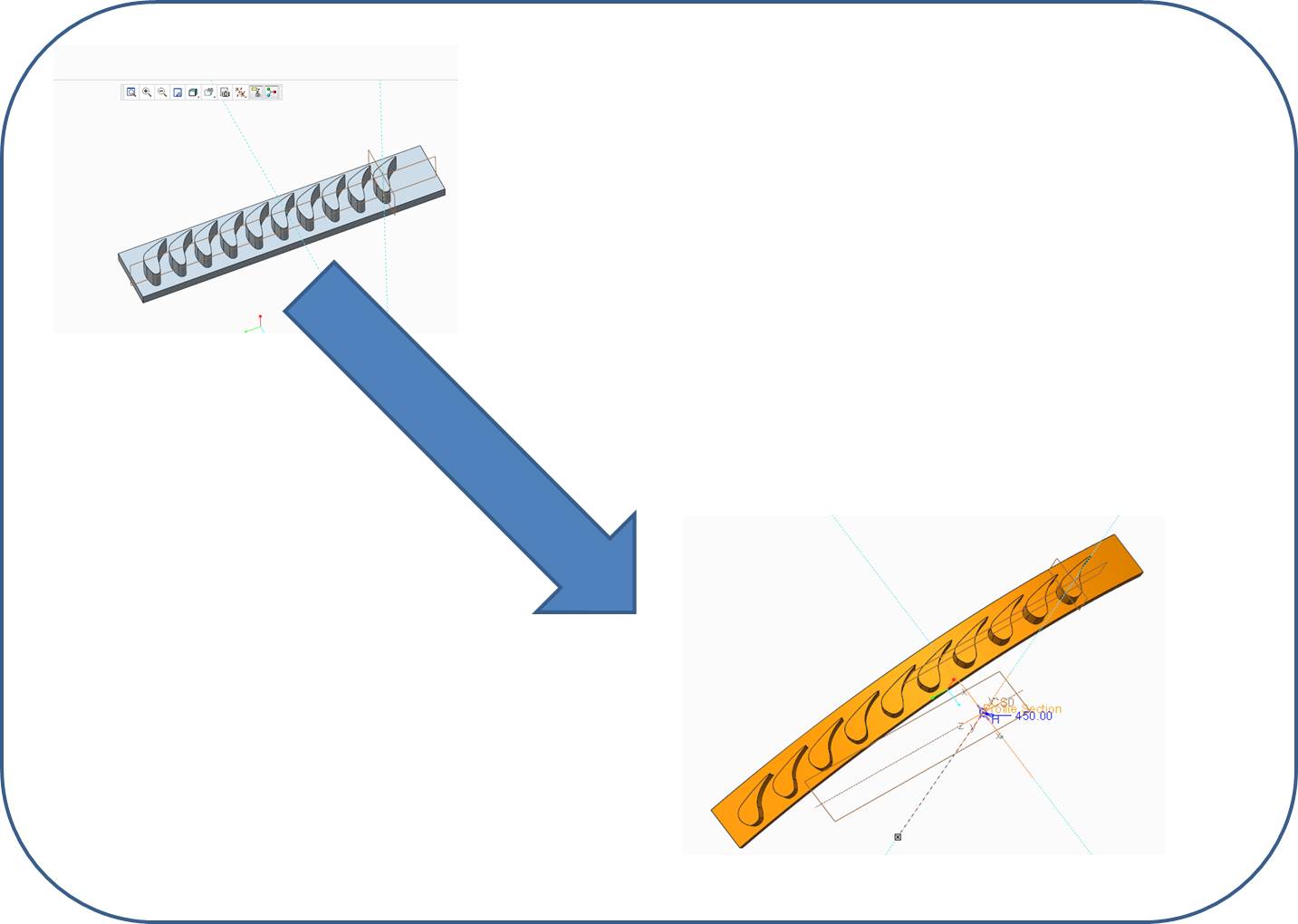

Here is an application I was using it for. The part is spherical. Basically a roll formed metal part. Sheetmetal, in this case can only for forms. It cannot give me an accurate flat pattern (not easily, anyway).

Since I want the flat version to be the template, I need to understand when the command is true to the original and when it stretches/compresses things. Also of interest is this Normals Reference Section.

I can see how this is a Spinal Bend on steroids. And Spinal Bends are notorious about excessive deformation. So I need some level of confirmation of what is going on behind the scene.

This part is straight forward. Toroidal bend of the solid and the curve section; length and radius control; default everything else. What I'd like to do is make a somewhat distorted version that follows a more elliptical path.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Man, that's a NEAT pair of sunglasses! ![]()

Hmm, I'd probably model that as a datum curve to simulate the flat pattern, then wrap that curve on an extruded surface with the short side arc. Then I'd use the curve as a cut. Then I'd thicken the surface so that the original surface was retained, and the thickened surface was the one where the metal has stretched. Then I'd do a spinal bend on the whole thing, making sure my spine was the exact length, and in the right direction.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Ha!... yea, that's why I like Toroidal Bend ![]() It is a simple flat model that I want to use as a starting pattern.

It is a simple flat model that I want to use as a starting pattern.

I made the mating part, slightly squished version using the Warp command (Warp is a -very- weak command as you have very little control). This one uses the curve-circles you see inscribed. I then offset the outside surface and flattened the quilt (another really messy command!). That flattened quilt is the pattern for the mating part.

I also had to report a bug with toroidal Bend today. It will be submitted as an SPR. I tried to remove the curves from the toroidal bend but one circle remained. It wasn't listed but when I tried to delete the associated sketch, it wanted to delete the toroidal bend. Something got corrupted and PTC will have to take a look.

This is what I was after...

For the flatten quilt, I had to leave a cylinder in the center so the origin "point" would be close enough to the model... and then it tells me the x-direction was -too- close to the model. That command is like pulling teeth.

I am satisfied that with a roll-press, the two parts could be formed to within acceptable limits of the model based on the two flat patterns I now have available.

This was the challenge I was hoping the Toroidal Bend command could solve in a single step... the slight flattening of the "forward" face but still maintain a relatively coincident surface at the pivots (ends).

With the warp tool I was able to "freeze" the ends while moving the face in +Y and moving each half one material thickness in +/-X (fix the bounding box at 50% and 100% on each side). What is lacking in the warp command is specificity. It is a "general" move. You can control the bounding box well enough but the move deltas have no available references -except- the limits of the bounding box. This makes the geometry modifications "relative" and much less precise than I would normally want.

In this case, it is "good enough" (GAWD I DISLIKE THAT PHRASE!).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Antonius Dirriwachter wrote:

Ha!... yea, that's why I like Toroidal Bend

It is a simple flat model that I want to use as a starting pattern.

I made the mating part, slightly squished version using the Warp command (Warp is a -very- weak command as you have very little control). This one uses the curve-circles you see inscribed. I then offset the outside surface and flattened the quilt (another really messy command!). That flattened quilt is the pattern for the mating part.

I also had to report a bug with toroidal Bend today. It will be submitted as an SPR. I tried to remove the curves from the toroidal bend but one circle remained. It wasn't listed but when I tried to delete the associated sketch, it wanted to delete the toroidal bend. Something got corrupted and PTC will have to take a look.

...<snip>

This SPR was resolved and will be included in M080.

"SPR 2179728 submitted to address the issue has been resolved in Creo Parametric 2.0 M080."

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello,

Can you explain the meaning of " a rotatable geometry coordinate system"? I tried the Tire tutorial, and I cannot get past the sketching step...![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You need to use a datum coordinate system in your sketch, not the construction one. X is the -direction- of the rotation axis and +Y points away from the rotation axis.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

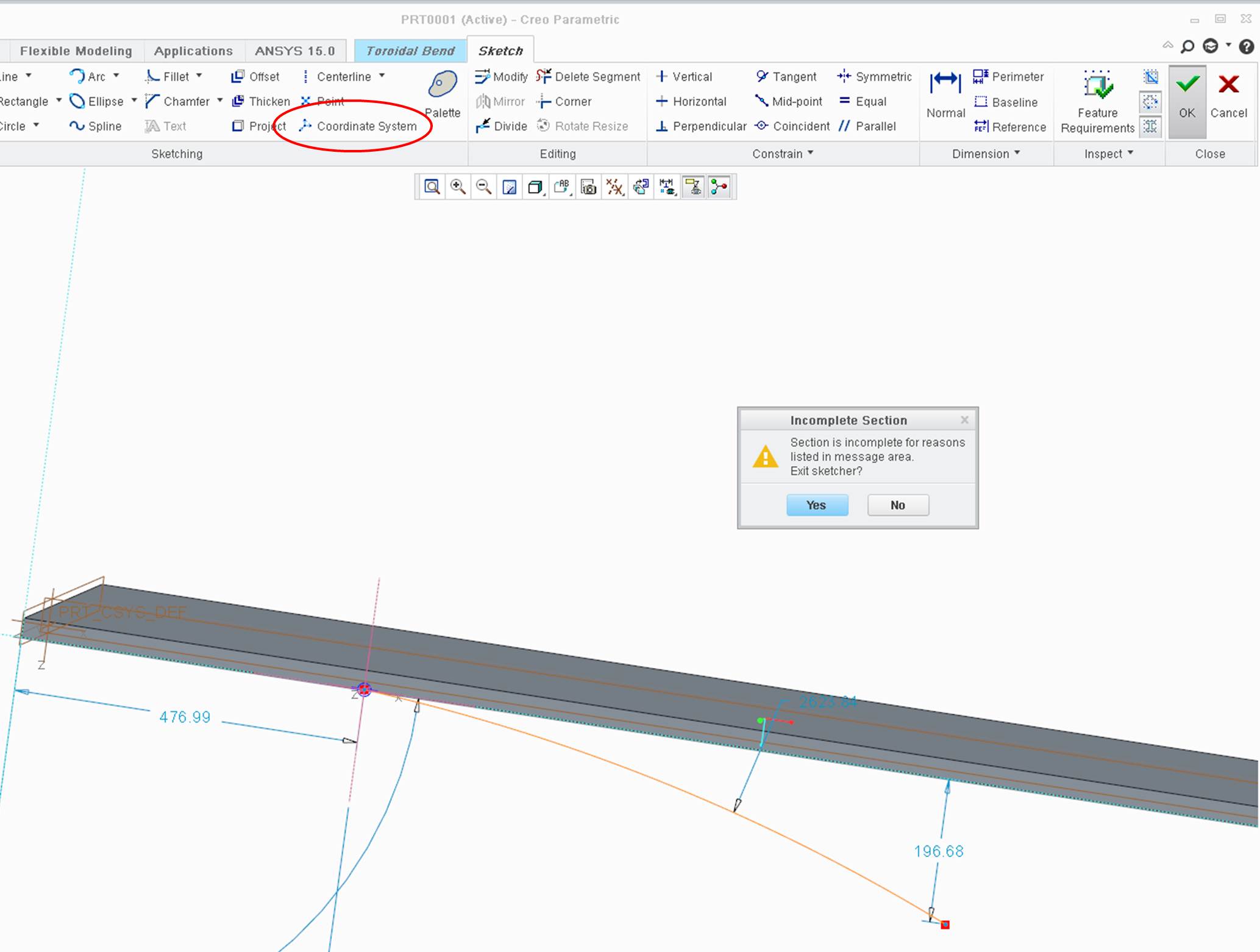

Hello Antonius,

Can you tell me where is the problem in the attached picture?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Stephane,

Did you add coordinate system at the begining of the sketched curve??

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Right, you need to add a datum coordinate system -inside- the sketch.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I added the coordinate system inside the sketch. you can see it on the left side in purple, close to the construction coordinate system. Also, it is not positionned at the beginning of the sketched curve ( but neither is the coordinate system of the example presented in CREO help...).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

-which- sketch button did you use to create the coordinate system? The datum one or the construction one?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello,

You can see in the picture below the button I am using.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Ok Igot it. All I had to do is take a look to the left side of th ribbon to find the correct button. sorry for the inconvenience. Another question: Is it possible to prevent the surface of the solid to stretch??? I would like to preserve the shape of the nozzles, is it possible?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Unfortunately, bend operations are just that, they distort materials based on the shape you make.

A good way to manage critical geometry along a 3D surface is to use patterns using the "FILL" option.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The threads bove aer really impressive and useful. Nut I am facing wierd problem in Toroidal Bend, i.e.; no matter what I do, I am unable to switch the directuion of bend for the toroidal bend. Means I want it to get my features within the "circlular shape" but the feature are on the external part of the bend...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You want the dimples on the inside of the cylinder? Try changing the orienration of the sketched coordinate system.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

thanks a lot...it was so obvious I didn't try it out...

Thanks once again...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Happy to help ![]()