Community Tip - Learn all about the Community Ranking System, a fun gamification element of the PTC Community. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Convert PRT to SKEL

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Convert PRT to SKEL

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Convert PRT to SKEL

Hi,

I got "Master" file (prt) and I want to convert it to skel without external ref.

Is it possible?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

There is no easy answer for this but for the most part, fabrication of fitted pipes is pretty much what the Creo operations do. For normal edges you need to have the sheet metal functionality. That might be another fish you don't want to fry. I'd say scribe the inside and the outside and run a sweep through both.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Please share your file in Creo2 or in step/iges so that I can understand better your intent. Thanks

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

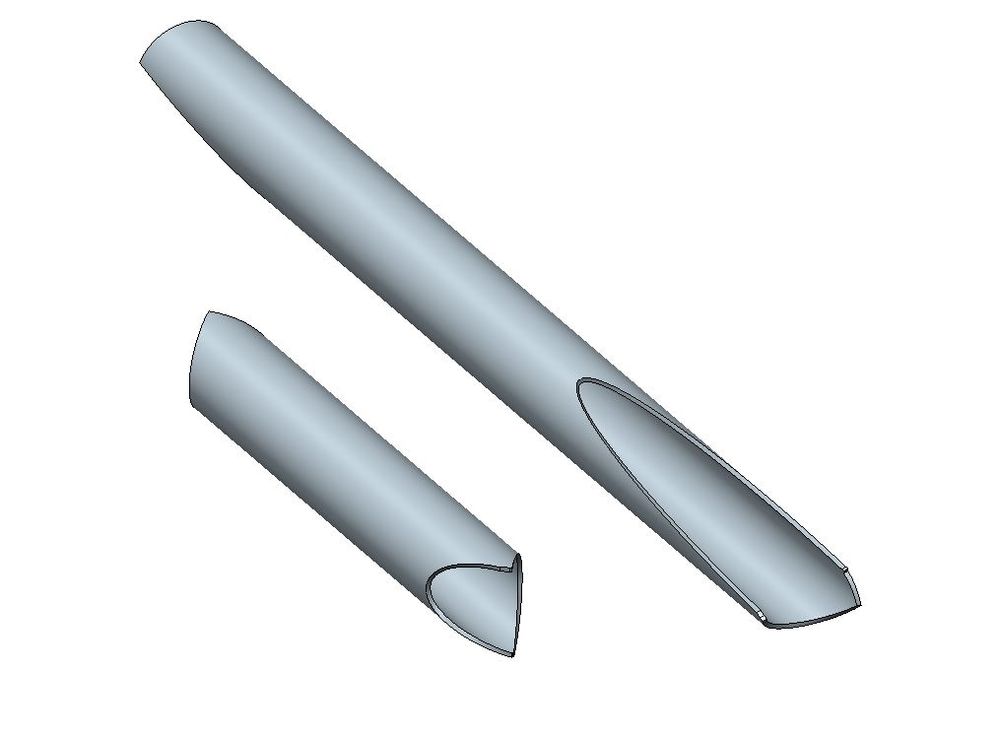

Here it is. The one from the picture (worst case) and another with a more common geometry.

Forgot to say I'm using Creo 4.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I approached this using surfaces:

1. Create the outer surface of the pipe

2. trim sut using the outer edge

3. Thicken it to the correct thickness (1.25). With this , the cut is perfectly normal to both outer and inner surface.

Is this what you wanted to do?

I attached here the Creo2 files for your reference.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Pretty close, trimming this surface with both the inner and outer edges would be perfect, if possible.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

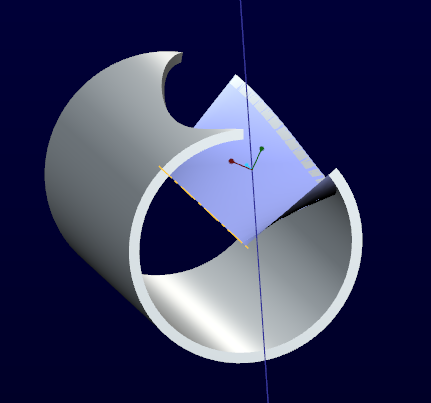

I just did the surface to test the normal condition.

It is a simple thickened surface. You choose how to define it. Point is to define a surface model with the completed cuts and then thicken the tube.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

What you're talking about is NOT always normal to the surface if you mean the surface of the tube you have shown. It's more a boolian operation of a cylinder removed from the tube shown in the diamater of the tube it mates with that you haven't shown. This should be easy if the tubes are of a constant round cross section. I would model all these tubes top-down using trajectory curves in the center of the circular cross section that you can use later to sweep cuts along to get the shapes you want.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

What is suggested follows my earlier suggestion... using sheet-metal functionality.

Sheet-metal does just that; creating thickened surfaces.

The attached file proves that these surfaces are normal.

I projected and pulled an extended surface to the centerline.

(Creo 2.0 commercial file attached)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It is indeed a removed cylinder, and if I understand how Framework works, the geometries are generated from trajectories and constant cross-sections. The problem is that the resulting geometry is not suitable for simple laser-cutting machines as they cannot cut angled to the surface.