Community Tip - You can Bookmark boards, posts or articles that you'd like to access again easily! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Counterbore/Countersink hole Notes on Drawing.

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Counterbore/Countersink hole Notes on Drawing.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Counterbore/Countersink hole Notes on Drawing.

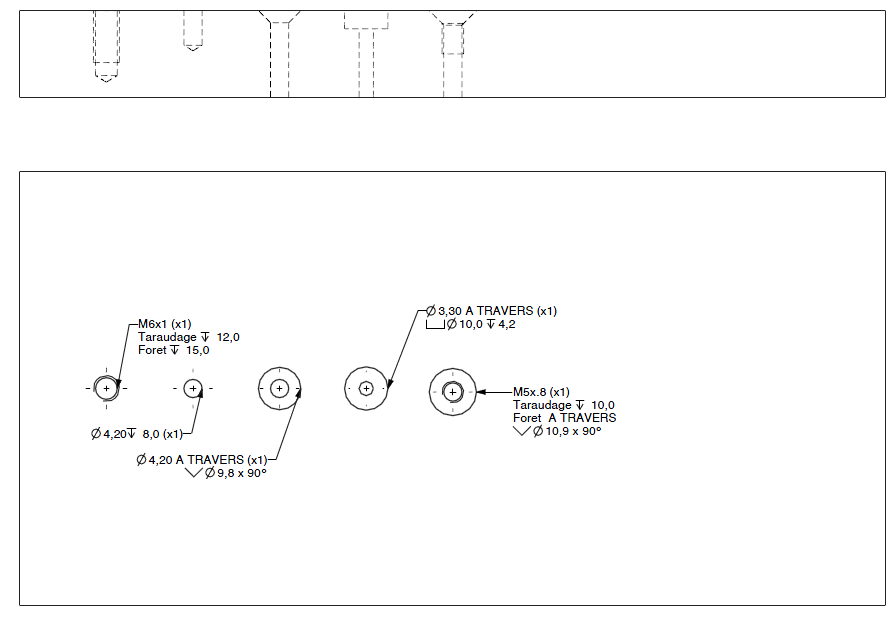

Pro/E allows us to to create Countersunk and Counterbore holes in the model. Is there a way to get the note on the drawing to read in the format shown in the attched image?

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

'format' of the note in the .hol file. Below you can see what this

looks like in notepad...

You want to edit the CALLOUT_FORMAT line. If I remember correctly you

will need to create different .hol files for each different callout you

want though. (i.e. one for CBore and one for CSink) This is due to

wanting some things on one call out and others on another callout. I

was hoping they would have this fixed with Creo. Can anyone chime in on

that?

Tony

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Tom U.

TABLE_DATA

PRO_VERSION 24

THREAD_SERIES UNC

CLASS 2B

TABLE_UNITS inch

DEPTH_RATIO 1.5

CALLOUT_FORMAT &DIAMETER

THREAD_DATA

FASTENER_ID BASIC_DIAM THREAD TAP_DR TAP_DEC PERCENT_THREAD CLEAR_DR_CLOSE CLOSE_DEC CLEAR_DR_FREE FREE_DEC CLEAR_DR_MED MED_DEC CBOREDIAM CBOREDEPTH CSINKDIAM CSINKANGLE BOTCSINKDIAM BOTCSINKANGLE

1-64 0.073 64 #53 0.0595 81% #48 0.0760 #46 0.0810 0 0 0.1563 0.073 0.146 82 0.146 82

2-56 0.086 56 #50 0.0700 62% #43 0.0890 #41 0.0960 0 0 0.1875 0.086 0.172 82 0.172 82

3-48 0.099 48 #47 0.0785 69% #37 0.1040 #35 0.1100 0 0 0.2188 0.099 0.199 82 0.199 82

4-40 0.112 40 #43 0.0890 65% #32 0.1160 #30 0.1285 0 0 0.2188 0.112 0.225 82 0.225 82

5-40 0.125 40 #38 0.1015 65% #30 0.1285 #29 0.1360 0 0 0.2500 0.125 0.252 82 0.252 82

6-32 0.138 32 #36 0.1065 71% #27 0.1440 #25 0.1495 0 0 0.2813 0.138 0.279 82 0.279 82

8-32 0.164 32 #29 0.1360 62% #18 0.1695 #16 0.1770 0 0 0.3125 0.164 0.332 82 0.332 82

10-24 0.190 24 #25 0.1495 69% 13/64 0.2031 #7 0.2010 0 0 0.3750 0.190 0.385 82 0.411 82

12-24 0.216 24 #16 0.1770 66% #2 0.2210 1 0.2280 0 0 0 0.216 0.438 82 0.438 82

14-20 0.242 20 #10 0.1935 75% D 0.2460 F 0.2570 0 0 0 0.242 0 82 0 82

1/4-20 0.250 20 #7 0.2010 70% 9/32 0.2813 H 0.2660 0 0 0.4375 0.250 0.507 82 0.531 82

5/16-18 0.3125 18 F 0.2570 72% 11/32 0.3437 Q 0.3320 0 0 0.5313 0.313 0.635 82 0.656 82

3/8-16 0.375 16 5/16 0.3125 72% 13/32 0.4063 X 0.3970 0 0 0.6250 0.375 0.762 82 0.781 82

7/16-14 0.4375 14 U 0.3680 70% 15/32 0.4687 15/32 0.4687 0 0 0.7188 0.438 0.812 82 0.844 82

1/2-13 0.500 13 27/64 0.4219 73% 17/32 0.5313 17/32 0.5312 0 0 0.8125 0.500 0.875 82 0.938 82

9/16-12 0.5625 12 31/64 0.4843 68% 0 0 0 0 0 0 0 0.563 1.000 82 1.063 82

5/8-11 0.625 11 17/32 0.5312 75% 21/32 0.6563 0 0 0 0 1.0000 0.625 1.125 82 1.188 82

3/4-10 0.750 10 21/32 0.6562 68% 25/32 0.7813 0 0 0 0 1.1875 0.750 1.375 82 1.438 82

7/8-9 0.875 9 49/64 0.7656 72% 29/32 0.9063 0 0 0 0 1.3750 0.875 0 82 0 82

1-8 1.000 8 7/8 0.8750 73% 1-1/32 1.0313 0 0 0 0 1.6250 1.000 0 82 0 82

1-1/8-7 1.125 7 63/64 0.9843 0 0 0 0 0 0 0 0 1.125 0 82 0 82

1-1/4-7 1.250 7 1-7/64 1.1093 0 1-5/16 1.3125 0 0 0 0 2.0000 1.250 0 82 0 82

DEFAULT_CALLOUT_FORMAT_DATA

HOLE_TYPE THREAD DRILLED_DEPTH THREAD_DEPTH CSINK CBORE EXIT_CSINK CALLOUT_FORMAT

CLEARANCE NO THRU_ALL NA NO NO NO &PATTERN_NO X &METRIC_SIZE &THREAD_SERIES - &THREAD_CLASS &STD_HOLE_TYPE &VAR_THREAD &THREAD_DEPTH

CLEARANCE NO THRU_NEXT NA NO NO NO &PATTERN_NO X &METRIC_SIZE &THREAD_SERIES - &THREAD_CLASS &STD_HOLE_TYPE &VAR_THREAD &THREAD_DEPTH

CLEARANCE NO THRU_UNTIL NA NO NO NO &PATTERN_NO X &METRIC_SIZE &THREAD_SERIES - &THREAD_CLASS &STD_HOLE_TYPE &VAR_THREAD &THREAD_DEPTH

CLEARANCE NO TO_SEL NA NO NO NO &PATTERN_NO X &METRIC_SIZE &THREAD_SERIES - &THREAD_CLASS &STD_HOLE_TYPE &VAR_THREAD &THREAD_DEPTH

CLEARANCE NO THRU_ALL NA NO NO YES &PATTERN_NO X &METRIC_SIZE &THREAD_SERIES - &THREAD_CLASS &STD_HOLE_TYPE &VAR_THREAD &THREAD_DEPTH /EXIT<ctrl-a>w<ctrl-b><ctrl-a>n<ctrl-b> &BOTCSINK_DIAM X &BOTCSINK_ANGLE[.1]<ctrl-a>$<ctrl-b>

CLEARANCE NO THRU_ALL NA NO YES NO &PATTERN_NO X &METRIC_SIZE &THREAD_SERIES - &THREAD_CLASS &STD_HOLE_TYPE &VAR_THREAD &THREAD_DEPTH /<ctrl-a>v<ctrl-b><ctrl-a>n<ctrl-b> &Cbore_diameter X &Cbore_depth<ctrl-a>x<ctrl-b>

CLEARANCE NO THRU_NEXT NA NO YES NO &PATTERN_NO X &METRIC_SIZE &THREAD_SERIES - &THREAD_CLASS &STD_HOLE_TYPE &VAR_THREAD &THREAD_DEPTH /<ctrl-a>v<ctrl-b><ctrl-a>n<ctrl-b> &Cbore_diameter X &Cbore_depth<ctrl-a>x<ctrl-b>

CLEARANCE NO THRU_UNTIL NA NO YES NO &PATTERN_NO X &METRIC_SIZE &THREAD_SERIES - &THREAD_CLASS &STD_HOLE_TYPE &VAR_THREAD &THREAD_DEPTH /<ctrl-a>v<ctrl-b><ctrl-a>n<ctrl-b> &Cbore_diameter X &Cbore_depth<ctrl-a>x<ctrl-b>

CLEARANCE NO TO_SEL NA NO YES NO &PATTERN_NO X &METRIC_SIZE &THREAD_SERIES - &THREAD_CLASS &STD_HOLE_TYPE &VAR_THREAD &THREAD_DEPTH /<ctrl-a>v<ctrl-b><ctrl-a>n<ctrl-b> &Cbore_diameter X &Cbore_depth<ctrl-a>x<ctrl-b>

CLEARANCE NO THRU_ALL NA NO YES YES &PATTERN_NO X &METRIC_SIZE &THREAD_SERIES - &THREAD_CLASS &STD_HOLE_TYPE &VAR_THREAD &THREAD_DEPTH /<ctrl-a>v<ctrl-b><ctrl-a>n<ctrl-b> &Cbore_diameter X /EXIT<ctrl-a>w<ctrl-b><ctrl-a>n<ctrl-b> &BOTCSINK_DIAM X &Cbore_depth<ctrl-a>x<ctrl-b>

CLEARANCE NO THRU_ALL NA YES NO NO &PATTERN_NO X &METRIC_SIZE &THREAD_SERIES - &THREAD_CLASS &STD_HOLE_TYPE &VAR_THREAD &THREAD_DEPTH /<ctrl-a>w<ctrl-b><ctrl-a>n<ctrl-b> &Csink_diameter X &Csink_angle[.1]<ctrl-a>$<ctrl-b>

CLEARANCE NO THRU_NEXT NA YES NO NO &PATTERN_NO X &METRIC_SIZE &THREAD_SERIES - &THREAD_CLASS &STD_HOLE_TYPE &VAR_THREAD &THREAD_DEPTH /<ctrl-a>w<ctrl-b><ctrl-a>n<ctrl-b> &Csink_diameter X &Csink_angle[.1]<ctrl-a>$<ctrl-b>

CLEARANCE NO THRU_UNTIL NA YES NO NO &PATTERN_NO X &METRIC_SIZE &THREAD_SERIES - &THREAD_CLASS &STD_HOLE_TYPE &VAR_THREAD &THREAD_DEPTH /<ctrl-a>w<ctrl-b><ctrl-a>n<ctrl-b> &Csink_diameter X &Csink_angle[.1]<ctrl-a>$<ctrl-b>

CLEARANCE NO TO_SEL NA YES NO NO &PATTERN_NO X &METRIC_SIZE &THREAD_SERIES - &THREAD_CLASS &STD_HOLE_TYPE &VAR_THREAD &THREAD_DEPTH /<ctrl-a>w<ctrl-b><ctrl-a>n<ctrl-b> &Csink_diameter X &Csink_angle[.1]<ctrl-a>$<ctrl-b>

CLEARANCE NO THRU_ALL NA YES NO YES &PATTERN_NO X &METRIC_SIZE &THREAD_SERIES - &THREAD_CLASS &STD_HOLE_TYPE &VAR_THREAD &THREAD_DEPTH /<ctrl-a>w<ctrl-b><ctrl-a>n<ctrl-b> &Csink_diameter X&Csink_angle[.1]<ctrl-a>$<ctrl-b>

CLEARANCE NO THRU_ALL NA YES YES NO &PATTERN_NO X &METRIC_SIZE &THREAD_SERIES - &THREAD_CLASS &STD_HOLE_TYPE &VAR_THREAD &THREAD_DEPTH /<ctrl-a>v<ctrl-b><ctrl-a>n<ctrl-b> &Cbore_diameter X /<ctrl-a>w<ctrl-b><ctrl-a>n<ctrl-b> &Csink_diameter X &Cbore_depth<ctrl-a>x<ctrl-b>

CLEARANCE NO THRU_NEXT NA YES YES NO &PATTERN_NO X &METRIC_SIZE &THREAD_SERIES - &THREAD_CLASS &STD_HOLE_TYPE &VAR_THREAD &THREAD_DEPTH /<ctrl-a>v<ctrl-b><ctrl-a>n<ctrl-b> &Cbore_diameter X /<ctrl-a>w<ctrl-b><ctrl-a>n<ctrl-b> &Csink_diameter X &Cbore_depth<ctrl-a>x<ctrl-b>

CLEARANCE NO THRU_UNTIL NA YES YES NO &PATTERN_NO X &METRIC_SIZE &THREAD_SERIES - &THREAD_CLASS &STD_HOLE_TYPE &VAR_THREAD &THREAD_DEPTH /<ctrl-a>v<ctrl-b><ctrl-a>n<ctrl-b> &Cbore_diameter X /<ctrl-a>w<ctrl-b><ctrl-a>n<ctrl-b> &Csink_diameter X &Cbore_depth<ctrl-a>x<ctrl-b>

CLEARANCE NO TO_SEL NA YES YES NO &PATTERN_NO X &METRIC_SIZE &THREAD_SERIES - &THREAD_CLASS &STD_HOLE_TYPE &VAR_THREAD &THREAD_DEPTH /<ctrl-a>v<ctrl-b><ctrl-a>n<ctrl-b> &Cbore_diameter X /<ctrl-a>w<ctrl-b><ctrl-a>n<ctrl-b> &Csink_diameter X &Cbore_depth<ctrl-a>x<ctrl-b>

CLEARANCE NO THRU_ALL NA YES YES YES &PATTERN_NO X &METRIC_SIZE &THREAD_SERIES - &THREAD_CLASS &STD_HOLE_TYPE &VAR_THREAD &THREAD_DEPTH /<ctrl-a>v<ctrl-b><ctrl-a>n<ctrl-b> &Cbore_diameter X /<ctrl-a>w<ctrl-b><ctrl-a>n<ctrl-b> &Csink_diameter X &Cbore_depth<ctrl-a>x<ctrl-b> /EXIT<ctrl-a>w<ctrl-b><ctrl-a>n<ctrl-b> &BOTCSINK_DIAM X &BOTCSINK_ANGLE[.1]<ctrl-a>$<ctrl-b>

DRILLED NO THRU_ALL NA NO NO NO <ctrl-a>n<ctrl-b> &DIAMETER[.2]THRU

DRILLED NO THRU_NEXT VAR NO NO NO NOT SET

DRILLED NO THRU_UNTIL VAR NO NO NO NOT SET

DRILLED NO TO_SEL VAR NO NO NO NOT SET

DRILLED NO VAR NA NO NO NO <ctrl-a>n<ctrl-b> &DIAMETER[.2] <ctrl-a>n<ctrl-b> &DRILL_DEPTH

DRILLED NO THRU_ALL NA NO NO YES NOT SET

DRILLED NO VAR NA NO NO YES NOT SET

DRILLED NO THRU_ALL NA NO YES NO <ctrl-a>n<ctrl-b> &DIAMETER[.2]THRU /<ctrl-a>v<ctrl-b> <ctrl-a>n<ctrl-b> &CBOREDIAM<ctrl-a>x<ctrl-b> &CBOREDEPTH

DRILLED NO THRU_NEXT VAR NO YES NO NOT SET

DRILLED NO THRU_UNTIL VAR NO YES NO NOT SET

DRILLED NO TO_SEL VAR NO YES NO NOT SET

DRILLED NO VAR NA NO YES NO NOT SET

DRILLED NO THRU_ALL NA NO YES YES NOT SET

DRILLED NO VAR NA NO YES YES NOT SET

DRILLED NO THRU_ALL NA YES NO NO <ctrl-a>n<ctrl-b> &DIAMETER[.2]THRU /<ctrl-a>w<ctrl-b> <ctrl-a>n<ctrl-b> &CSINKDIAM x &CSINKANGLE[.0]<ctrl-a>$<ctrl-b>

DRILLED NO THRU_NEXT VAR YES NO NO NOT SET

DRILLED NO THRU_UNTIL VAR YES NO NO NOT SET

DRILLED NO TO_SEL VAR YES NO NO NOT SET

DRILLED NO VAR NA YES NO NO NOT SET

DRILLED NO THRU_ALL NA YES NO YES NOT SET

DRILLED NO VAR NA YES NO YES NOT SET

DRILLED NO THRU_ALL NA YES YES NO NOT SET

DRILLED NO THRU_NEXT VAR YES YES NO NOT SET

DRILLED NO THRU_UNTIL VAR YES YES NO NOT SET

DRILLED NO TO_SEL VAR YES YES NO NOT SET

DRILLED NO VAR NA YES YES NO NOT SET

DRILLED NO THRU_ALL NA YES YES YES NOT SET

DRILLED NO VAR NA YES YES YES NOT SET

TAPERED YES VAR VAR NO NO NO NOT SET

TAPERED YES VAR VAR NO YES NO NOT SET

TAPERED YES VAR VAR YES NO NO NOT SET

TAPERED YES VAR VAR YES YES NO NOT SET

TAPPED YES THRU_ALL VAR NO NO NO TAP &FASTENER_ID <ctrl-a>x<ctrl-b> &THREAD_DEPTH / TAP DRILL THRU

TAPPED YES THRU_ALL THRU NO NO NO &FASTENER_ID &THREAD_SERIES - &THREAD_CLASS THRU

TAPPED YES THRU_NEXT VAR NO NO NO NOT SET

TAPPED YES THRU_UNTIL VAR NO NO NO NOT SET

TAPPED YES TO_SEL VAR NO NO NO NOT SET

TAPPED YES VAR VAR NO NO NO &FASTENER_ID &THREAD_CLASS/ <ctrl-a>X<ctrl-b> &THREAD_DEPTH

TAPPED YES THRU_ALL VAR NO NO YES NOT SET

TAPPED YES THRU_ALL THRU NO NO YES NOT SET

TAPPED YES THRU_ALL VAR NO YES NO NOT SET

TAPPED YES THRU_ALL THRU NO YES NO NOT SET

TAPPED YES THRU_NEXT VAR NO YES NO NOT SET

TAPPED YES THRU_UNTIL VAR NO YES NO NOT SET

TAPPED YES TO_SEL VAR NO YES NO NOT SET

TAPPED YES VAR VAR NO YES NO NOT SET

TAPPED YES THRU_ALL VAR NO YES YES NOT SET

TAPPED YES THRU_ALL THRU NO YES YES NOT SET

TAPPED YES THRU_ALL VAR YES NO NO NOT SET

TAPPED YES THRU_ALL THRU YES NO NO NOT SET

TAPPED YES THRU_NEXT VAR YES NO NO NOT SET

TAPPED YES THRU_UNTIL VAR YES NO NO NOT SET

TAPPED YES TO_SEL VAR YES NO NO NOT SET

TAPPED YES VAR VAR YES NO NO NOT SET

TAPPED YES THRU_ALL VAR YES NO YES NOT SET

TAPPED YES THRU_ALL THRU YES NO YES NOT SET

TAPPED YES THRU_ALL VAR YES YES NO NOT SET

TAPPED YES THRU_ALL THRU YES YES NO NOT SET

TAPPED YES THRU_NEXT VAR YES YES NO NOT SET

TAPPED YES THRU_UNTIL VAR YES YES NO NOT SET

TAPPED YES TO_SEL VAR YES YES NO NOT SET

TAPPED YES VAR VAR YES YES NO NOT SET

TAPPED YES THRU_ALL VAR YES YES YES NOT SET

TAPPED YES THRU_ALL THRU YES YES YES NOT SET

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Regards,

Bill

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

T

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

From Tom’s email show below showing the Default_Callout_Format_Data. Does anybody know if it’s possible when you have a clearance drill to differentiate between the Close Fit and Free Fit that Creo 2.0 now offers in this table? I can either call out the Free Fit or the Close Fit, but format of the note won’t change when switching between the two fits. I have attached my unc.hol to show you what I just created for my company.

[cid:image002.png@01CE1BD4.75E7B820][cid:image003.jpg@01CE1BD4.75E7B820]

[cid:image002.png@01CE1BD4.75E7B820][cid:image004.jpg@01CE1BD4.75E7B820]

Thanks in advance,

Carpe Diem,

"Happiness equals reality minus expectations"

Michael Heath

Schlumberger Reservoir Completions

14910 Airline Rd.

Rosharon, TX 77583

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Tom U.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks. That worked perfectly.

Mike

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

PRO_VERSION 24

THREAD_SERIES HELICAL

CLASS 2B

TABLE_UNITS inch

DEPTH_RATIO 1.25

CALLOUT_FORMAT <ctrl-a>w<ctrl-b> <ctrl-a>n<ctrl-b>&CSINKDIAM # .015

&CSINKANGLE[.0] $ # 5 $ / &METRIC_SIZE UNC-&THREAD_CLASS / &THREAD_SERIES

COIL INSERT / THD PER NASM33537 / FULL THD <ctrl-a>x<ctrl-b> MIN/ TAP

DRILL <ctrl-a>x<ctrl-b> # .010/ INSTALL INSERT .75-1.5 / TURNS BELOW

SURFACE

These take alot of work to get setup but hey can work the above Callout

format gives me this when I show the note on a drawing.

Brian L Taylor

Principal Technical Support Engineer

Mechanical Optical Electrical Center

Space and Airborne Systems

Raytheon Company

972-344-7697 (office)

-

13510 North Central Expressway

Dallas Tx 75243 USA

www.raytheon.com

Follow Raytheon On

This message contains information that may be confidential and privileged.

Unless you are the addressee (or authorized to receive mail for the

addressee), you should not use, copy or disclose to anyone this message or

any information contained in this message. If you have received this

message in error, please so advise the sender by reply e-mail and delete

this message. Thank you for your cooperation.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It is a lot of work, but like you said once you get it set up it’s absolutely fantastic. Now I get this automatically created when I put in a hole feature.

[cid:image001.jpg@01CE1BF7.301E3080]

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

[cid:image013.png@01CE1C0A.9D11C040]

PTC has a document that explains this and a SPR has been filed. You can read about it here:

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi All,

I'm struggling with this too, making a parametric hole note / call out. In my case, I can cause Creo to crash, pretty much on command when annotating a c'sunk hole. Instead of just making a note attached to the hole with manually entered numbers, I am using the "&adXX:X" system dims [dimension, then double click the hole edge to get a dim] in the note call-out; one for the smaller, inner dia, and the other for the larger, outer dia. SO, my hole note will have 3 lines, the first line being the small dia: "&adXX:X", the 2nd line will have the larger, c-sunk dia.: "\ /&adXX:X x 82°" and the last line (3rd line) is how many I have: "3 HOLES", per the ANSI standards.

It grabs them no problem,, and I have my hole note. all is good, so far. Even with the green dot saying it's all up to date & regenerated. But, then when I try to add a 2nd sheet to the drawing, crash! Even some printing tries have caused it to crash. Now, it does seem to work well if it's the first & only model. But, if I close, clean the memory, then re-open it, it will then crash upon adding the 2nd sheet... And, it only happens when I grab the two dimensions into a note. If I leave them as 2 dims, no problems..

I do this type of note routinely for rectangles, obrounds, and hex holes. But it's only the c-sunk holes that seem to crash my system.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi all,

Today, I had a bit spare time so I decided to customize my hole notes. I had already done for threaded holes, now it's done for countersink and counterbore holes. I'm quite happy about that as it's not a really easy job as usual with PTC.

Here's what I get now ! ![]()

As I'm note an egoist guy, I share my hole file ! It's for metric holes.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello everyone!

I use a similar .hol file to call out dowel holes. It works perfectly outside of Windchill. When I check in the model/drawing and open it via Creo View, the callout information is missing. Does anyone else have that problem?