Community Tip - Want the oppurtunity to discuss enhancements to PTC products? Join a working group! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Creating hole pattern in assembly with 5000 ho...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Creating hole pattern in assembly with 5000 holes - Regeneration issue

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Creating hole pattern in assembly with 5000 holes - Regeneration issue

Hi l,

I am using fill pattern and reference pattern to create assembly hole features. The pattern creation and performance is fine for arounf 500 holes, but my project requirement is to created more than 4000 holes and hence it take very long time and never gets completed. I need a suggestion to make this creation in quick time

Thanks

Dhamodharan

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Labels:

-

Assembly Design

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi,

creation of thousands of holes is not simple task. You have to experiment. If you upload your model, community members can help you. Use How to attach file when you Reply to a discussion. procedure.

MH

Martin Hanák

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The turbo pattern method is the best way to do this. It's been around forever and it works like a charm.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello Dhamodharan,

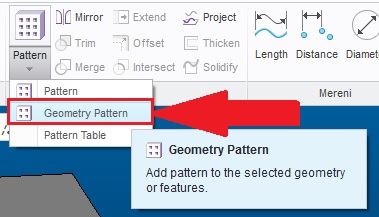

try to use/test GEOMETRY PATTERN. This pattern is much quicker to regenerate than normal pattern. Result is the same, but needs less computer performance.

See picture bellow.

Hope it can help...

Regards

Milan

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Geometry pattern is not available for me in assembly mode

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I am not sure if this has the quantity, but it may be helpful:

Re: Nest smoke alarm: How to create the "fibonacci-like" hole-pattern

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I train my users to try to stay away from assembly features as much as possible.

They are limited, use up extreme amounts of memory and are much more unstable.

If you want to mimic assembly features you can create a new part, inherit the part the holes need to go through and then create the geometry patterns in the newly created part. You would have to do this for all the parts the holes must be create in.

Finally assemble the newly created parts (with the hole pattern) in the assembly.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I'm not sure how well this would work because it's kind of a brute force method but could you make a "tool" part that has male extrudes that you could geometry pattern (especially if you could pattern of a pattern) that you assemble and use it to create a "Cut Out" feature (Component > Component Operations > Cut Out). When making large patterns you can break down the number of instances into 2 sets and it goes incredibly fast. If it was a regular rectangular pattern you could create a pattern of like 10 x 10 and then pattern that 8 x 5. Something to try at least.