- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Creo 3.0 repeat region?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Creo 3.0 repeat region?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Creo 3.0 repeat region?

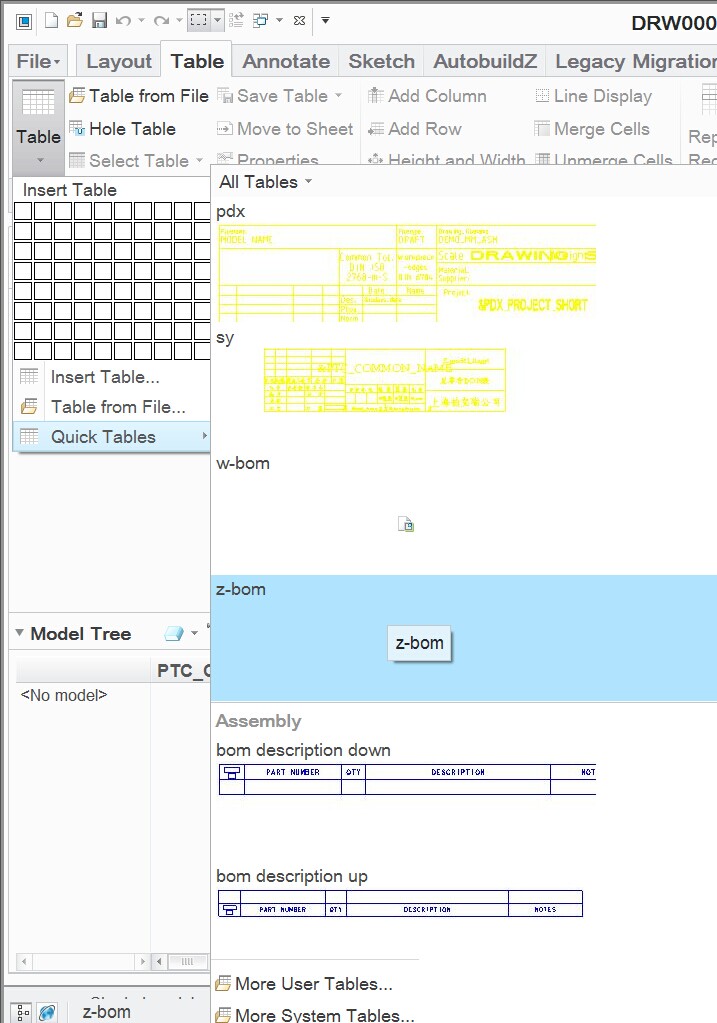

In modeling mode can you bring in a repeat region for a BOM to be populated? We are doing no drawings so I need to do this in the assembly models.

- Labels:

-

Assembly Design

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It doesn't seem familiar - where do you expect the repeat region to appear if it's not part of a drawing?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Robert,

repeat region can be created in a drawing, only. In Assembly mode, you can save Bill of materials into text file and put the contents of this file into annotation element.Unfortunatelly this annotation element is not updated dynamically, when assembly changes.

Martin Hanak

Martin Hanák

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This does seem like a gap in the whole "MBD" push. If this information isn't on a drawing, and it can't be put in the model, how is it supposed to be conveyed?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

In the MBD World, it needs to be conveyed in a separate parts list that can be generated from Windchill. Take a step back and think about your BOM balloons on a drawing, if you have 2 or more of the same part, the balloons really don't tell you much. Why do you need to see the parts pointed out on a view when the BOM is used by a different department to order the parts, they don't count the parts in the assembly view to make sure it matches the BOM quantity.

On drawing BOM is just something that has been done for decades and now it is time to change. There are lots of major companies that have gone drawing less.

The MBOM is what you need to convey in the Assembly Instructions (AI).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I thought the whole point of MBD was to have everything you need contained in the model. Are you saying you can't do MBD without a PDM system and extra MBOM documents? How does this approach help vendors who only get the models and don't have access to your PDM system? If I have to generate extra documents to ride along with the model, how is this any better than just creating a drawing? ![]()

Everything I've seen on MBD is an attempt to get the information currently on the drawing moved into the model. This is simply not possible today with the current 3D annotation capabilities.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

One typically distributes the balloons such that it is obvious which items are which. Without the balloons one has a list that shows maybe 150 screws and there is no idea where they go without having a computer to search for them. Worse, there's no MBD place to check-off which ones have been installed during the assembly process, a typical oversight in MBD systems architecture and there is no way to associate secondary information, such as torque notes and locking compound use.

So far, there is no MBD World, even though there are a few tiny MBD islands.

When Catia, Autodesk, Siemens, PTC, et al produce an interoperable, origin blind system for interchanging factory-floor process instructions, then it may be an MBD World. I think common use of cheap personal flying cars will appear first.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Were you at PTC Live, if so did you see our presentation on MDB and 3D PDF's thru Anark?

I will answer your questions:

Q: One typically distributes the balloons such that it is obvious which items are which. Without the balloons one has a list that shows maybe 150 screws and there is no idea where they go without having a computer to search for them.

A: The BOM is really for purchasing. We are transferring all new drawings to be separate parts list. The engineer that is creating the drawing already knows which part goes where. This is a mental shift. If you have Creo View then anyone can see assembly without the need for Creo Parametric. Adding BOM Balloons really just adds engineering time.

Q: Worse, there's no MBD place to check-off which ones have been installed during the assembly process, a typical oversight in MBD systems architecture

A: The Check-off process should be in the Assembly Instructions (AI) which could be leveraged in a 3D PDF.

Q: a typical oversight in MBD systems architecture and there is no way to associate secondary information, such as torque notes and locking compound use

A: Our 3D PDF's allow that with attached surface highlight.

I do understand that not everyone has the same budget, but this is the path that we are marching down. Anark has also been chosen by the Army and NIST for 3D PDF's and MBD.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Sales pitch for a proprietary lock-in solution. Does it depend on the use of 2D display screens?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Similar discussion going on here: I have a custom symbol that was created to add a suggested source table in model based definition. The creater of the c…

Maybe you can address how you would meet his needed functionality.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I disagree, the BOM is not only for purchasing. Maybe in big organizations such as the auto industry where every step in the assembly process is put into work instructions you can get away with that thinking, but the majority of small manufacturing and fab shops still need this information in the product definition for human consumption. Whether it's MBD or a drawing the product definition must be complete, unambiguous and flexible enough to accommodate the specialized needs of all industries. I agree with the earlier statement that the designer needs to be able to communicate assembly information such as where each of the 150 fastener PN's is supposed to go, torque information, adhesives, etc., without having users search through a massive model tree. There is no reason why all the functionallity of annotating a drawing (including a BOM table and balloons) cannot be moved into the model and published to a PDF for humans to view.

Creo recently added the combined views capability which has made it possible to produce a model with zoomed view states, layer control, sections and nicely organized dimensional annotations that emulate drawing views. In my opinion combined views are esier to work with than drawing views. This is a major step toward replacing a the full functionallity of a 2D drawing and gaining the advantage 3D model visualization. More functionality needs to be added though if you want all industries to adopt MBD.

I for one would love to adopt MBD as I see tremendous advantages for my company. The lack of being able to fully replace the drawing though is holding me back, in particular the fact that I haven't figured out how to place a BOM table in an annotation feature.

It seems every time I read a post about MBD there are 10 negative responces saying it doesn't work and will never happen. If you make it easy to migrate from drawings to MBD by providing full functionality then there will be nothing to complain about.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Not being able to do "drawing tables" in MBD is a big hole in capability. I have always created drawing tables for tracking (and summing) masses of products under-development. One "could" show all the parameters in a model tree. But you loose the all-important ability to sum the masses of thousands of object... not to mention the nice table formatting tools.

As a crappy work-around, I'll be adding a 3D note that refers people to a traditional drawing that has only tables in it... and any other capabilities MBD annotations don't yet support that I need.