Community Tip - Learn all about PTC Community Badges. Engage with PTC and see how many you can earn! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Creo NC has too many useless retract paths when I ...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Creo NC has too many useless retract paths when I was used Groove turning sequence

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Creo NC has too many useless retract paths when I was used Groove turning sequence

Hello Programer and PTC MF PM,

This issue that PTC e-support said this case is enhancement case so that I need your voting.

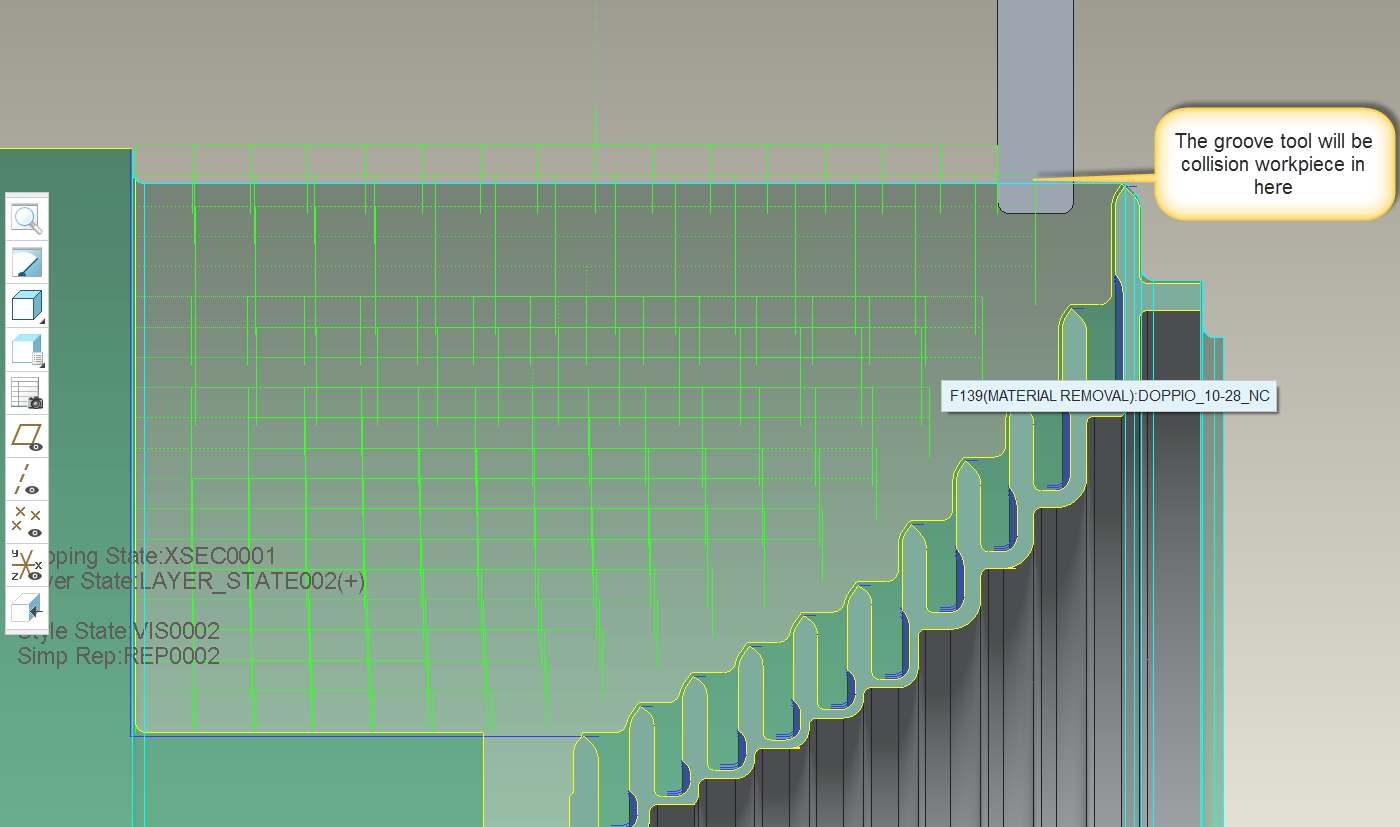

If set SCAN_TYPE parameter to TYPE_ONE_WALL, groove tool always go to "left side" to turn a cut then go to "right side" to turn a cut...same way continuity, because that always start turning from middle of groove area. However, this way will cause that machining time became longer.

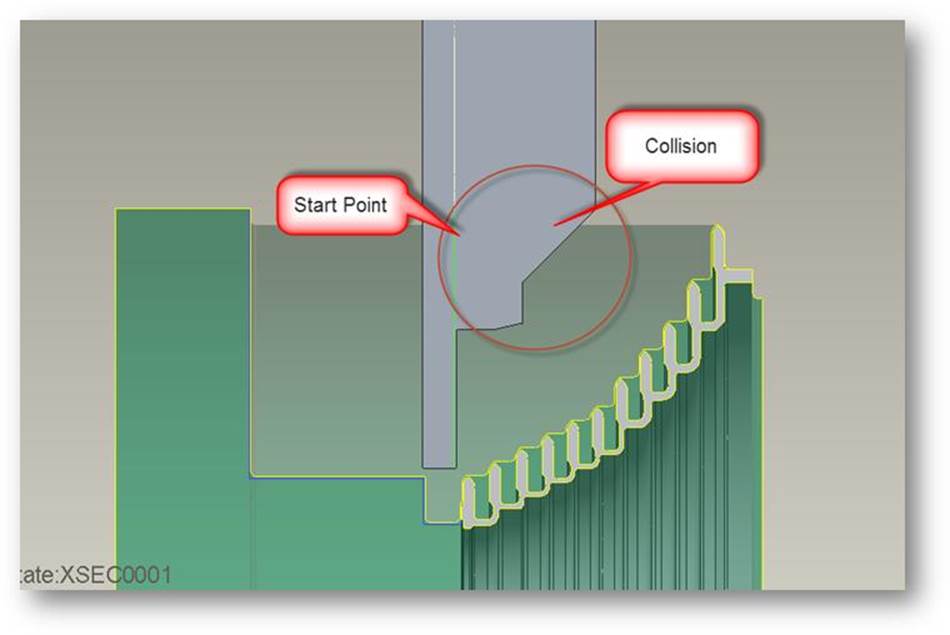

Important thing, the following first illustration is shown my existing turning part that cutting tool is collision the workpiece. If groove tool can start point in the groove area right edge that tool can be avoided collision issue happen.

This ticket C13614446 has been closed.

PTC E-support has suggested me that I can define SCAN_TYPE to TYPE_1_DIR, but I found that has too many rest material in the wall. Therefore, this way can't be solved my problem.

PTC e-support also tuaght me another way, but I found that will cause collision happens when I set parameters SCAN_TYPE to TYPE_ONE_WALL and DEEP_GROOVE_OPTION to BY_WIDTH. If PECK_DEPTH value great than 2.18, Collision will not happen. But I hopes that PECK_DEPTH value small than 2. So this way still fail.

I hope PTC can enhance TYPE_ONE_WALL efficiency in the future. I hope the groove tool start position can be the edge of groove area and the tool don't move to different direction during the groove turning.

- Labels:

-

General