Community Tip - You can subscribe to a forum, label or individual post and receive email notifications when someone posts a new topic or reply. Learn more! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Creo Simulate Random Dynamic Analysis Stress V...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Creo Simulate Random Dynamic Analysis Stress Values

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Creo Simulate Random Dynamic Analysis Stress Values

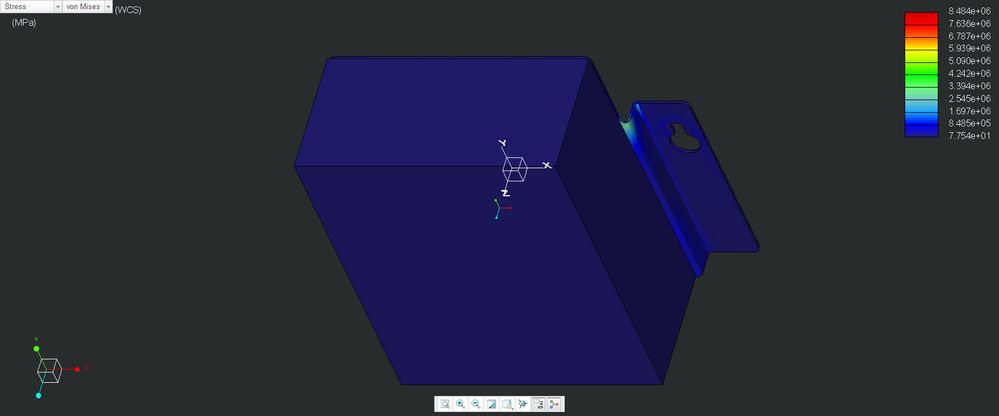

Our company has a reliability lab that utilizes a shaker table to do vibration testing on our products prior to full production. We had an aluminum bracket that failed, and after failure it was redesigned, and passed. I wanted to use Simulate to see if there was a way to consistently test other parts/assemblies prior to vibration testing to give us a better idea if they would pass or fail. The tensile yield strength of 5052 aluminum is 193 MPA, so I was expecting the failed part to be above that, and the part that passed, below that. However, after getting the assembly set up, and running the analysis the numbers I'm getting are in the 100s of thousands, showing basically that the entire part would fail. I've been working with PTC tech support as well, and they're not having any luck figuring out what is going on either.

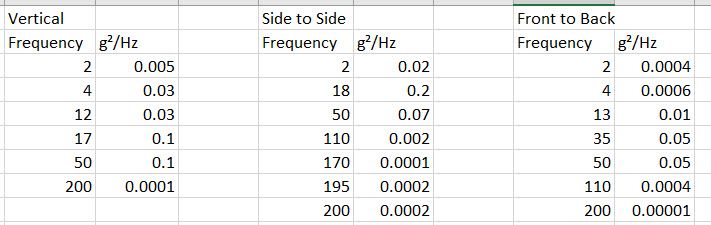

We are trying to use the data that we received from our reliability lab as far as the input for the vibration. The parts are tested in 3 different orientations. These values can be seen below.

- Labels:

-

Fastener Design

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Random Dynamic Anlysis is not a push button analysis. There is a lot of nuance in setting up the model. It is hard to diagonise without having access to the model but a couple of thoughts:

1. Make sure that the output of a measurement placed at the base excition equals the input

2. Make sure that all of your material properties are correct

3. Check your dampening coeffcient. If possible correlate with test results.

4. Make sure that your output intervals are not the default intervals. Simulate does not use a log method to calculate the response and if you leave the default intervals it can calculate to large a response due to resolution of the intervals.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

@Chris3 wrote:

Random Dynamic Anlysis is not a push button analysis. There is a lot of nuance in setting up the model. It is hard to diagonise without having access to the model but a couple of thoughts:

1. Make sure that the output of a measurement placed at the base excition equals the input

2. Make sure that all of your material properties are correct

3. Check your dampening coeffcient. If possible correlate with test results.

4. Make sure that your output intervals are not the default intervals. Simulate does not use a log method to calculate the response and if you leave the default intervals it can calculate to large a response due to resolution of the intervals.

I will go through the listed items and see if I missed anything. Also, I did attach the files in the original post, the zip file should have both the failed, and passed version of the aluminum bracket. Thanks for the response!!

Nick

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

@pkloninger-2 wrote:

example attached

regards

paul

The model you attached does appear to have more accurate stress values. I'll look through it and make sure I can understand how you set everything up. Thanks for the response!!

Nick