Community Tip - Learn all about the Community Ranking System, a fun gamification element of the PTC Community. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Did You Know? PTC Creo Intelligent Fastener Extens...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Did You Know? PTC Creo Intelligent Fastener Extension

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Did You Know? PTC Creo Intelligent Fastener Extension

You don’t have to be an engineer to understand the headaches that come from putting together countless screws, bolts, nuts, washers, and dowels. Especially if you’re the type of consumer that always has one piece left over after self-assembly. For design engineers assembling fasteners has always been a labor intensive task, requiring manual checks for hole alignment and fastener length, after design changes. The good news is that with PTC Creo Intelligent Fastener Extension (IFX) the time it takes to assemble fasteners can be reduced by up to 90% and those lengthy, traditionally manual design validation checks are now highly automated, improving productivity. In this post, Jim Barrett-Smith explains how to pattern a screw connection where multiple parts need to be drilled using IFX:

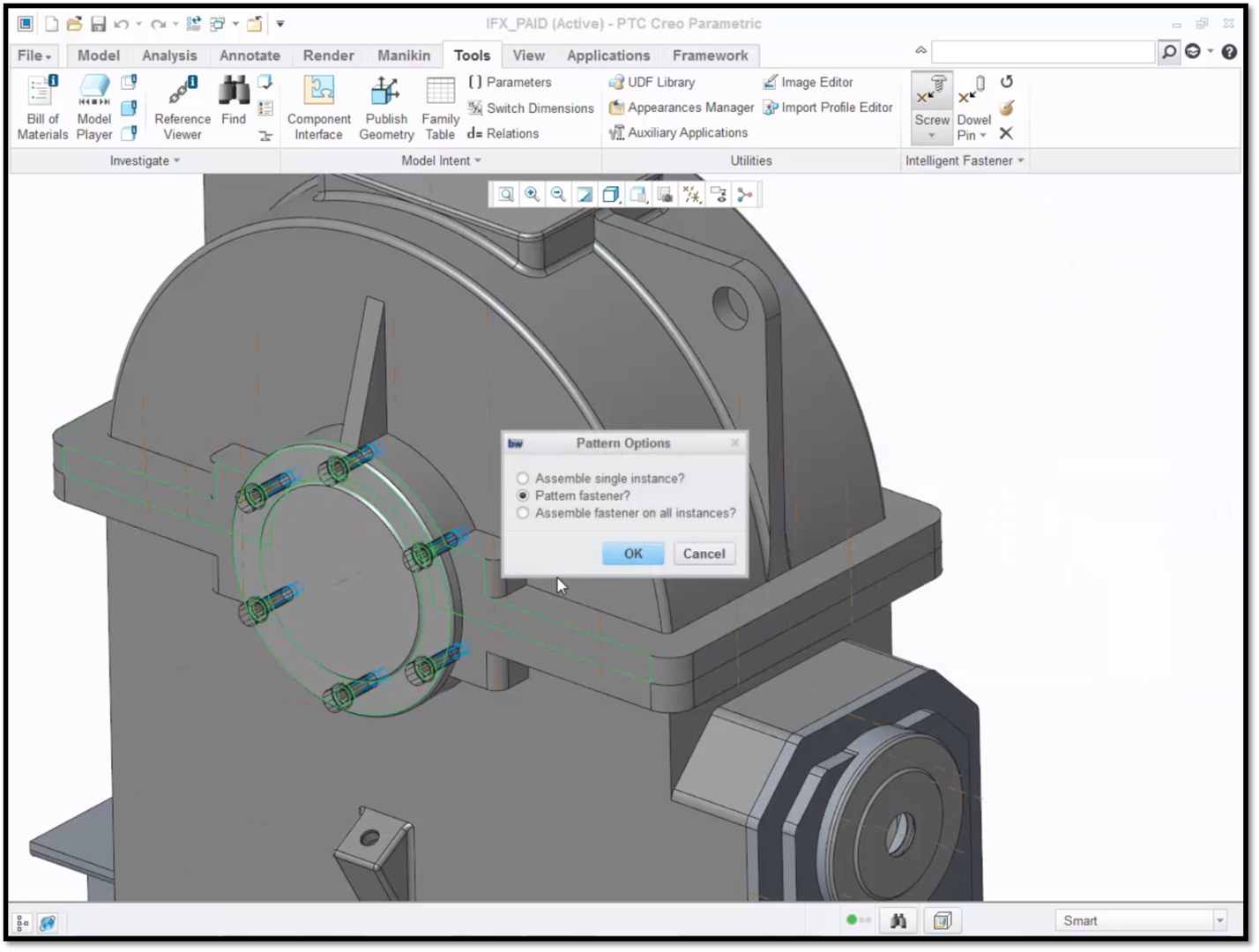

To assemble a screw connection, begin by navigating to the Tools tab and clicking Screw. This will open a dialogue box where you can select your placement references. Next, in the Screw Fastener Definition dialogue box select a fastener, washers, and nuts from the comprehensive library. Based on your placement references IFX knows how long the fastener should be, and if a hole already exists then you can use IFX to measure the hole. Now that IFX has the hole diameter and the thickness of the material being fastened, it will automatically select a fastener from the library. And during the reference selection, if you have selected a patterned hole, datum axis or datum point, IFX will ask you if you would like to assemble a single fastener, pattern the fastener or assemble individual fastener on all instances of the pattern. Finally IFX will automatically be create the holes in the required parts.

In this example, there are six fasteners to be assembled.

If you create a screw connection where one side of the placement surface is not parallel to the other, such as an i-beam, IFX provides you with the tools to keep the nut and bolt normal to a flat surface. You can do this by defining an Orientation in the Select References dialogue box.

Here you can see two green arrows, which indicates that a reference orientation has been defined.

To finalize the placement, use the Screw Fastener Definition dialogue box to select a wedge washer from the out of the box library.

The Screw Fastener Definition dialogue box provides a 2D Preview of your selections.

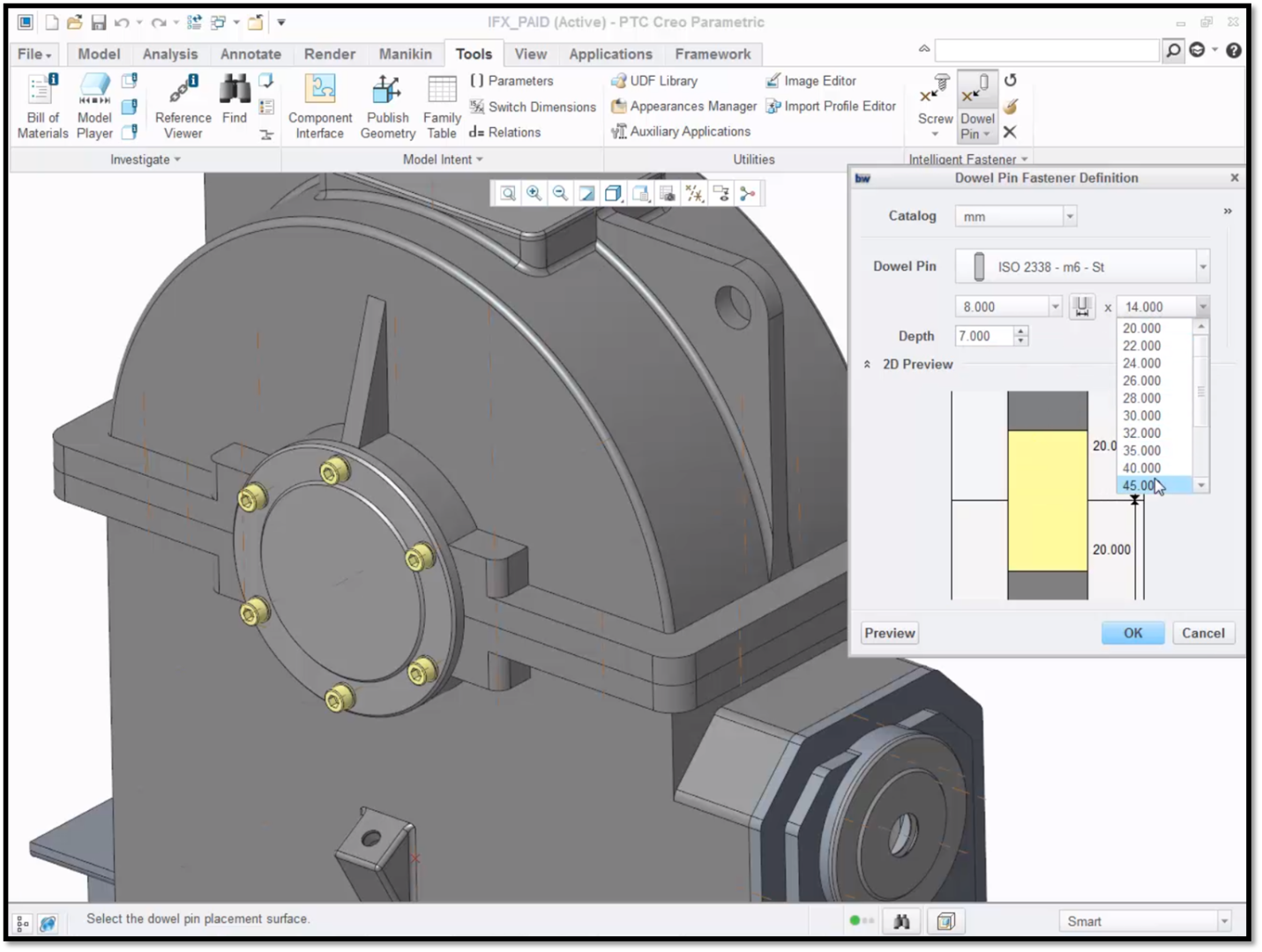

Assembling dowel pins follows the same process as assembling screw connections. First, click Dowel Pin to open the Select References dialogue box. Next, select the location and the parting surface for the dowel pin. Using the Dowel Pin Fastener Definition dialogue box, select your standards and hole definitions and click OK to insert the dowels.

The Dowel Pin Fastener Definition dialogue box also provides a 2D Preview of your selections.

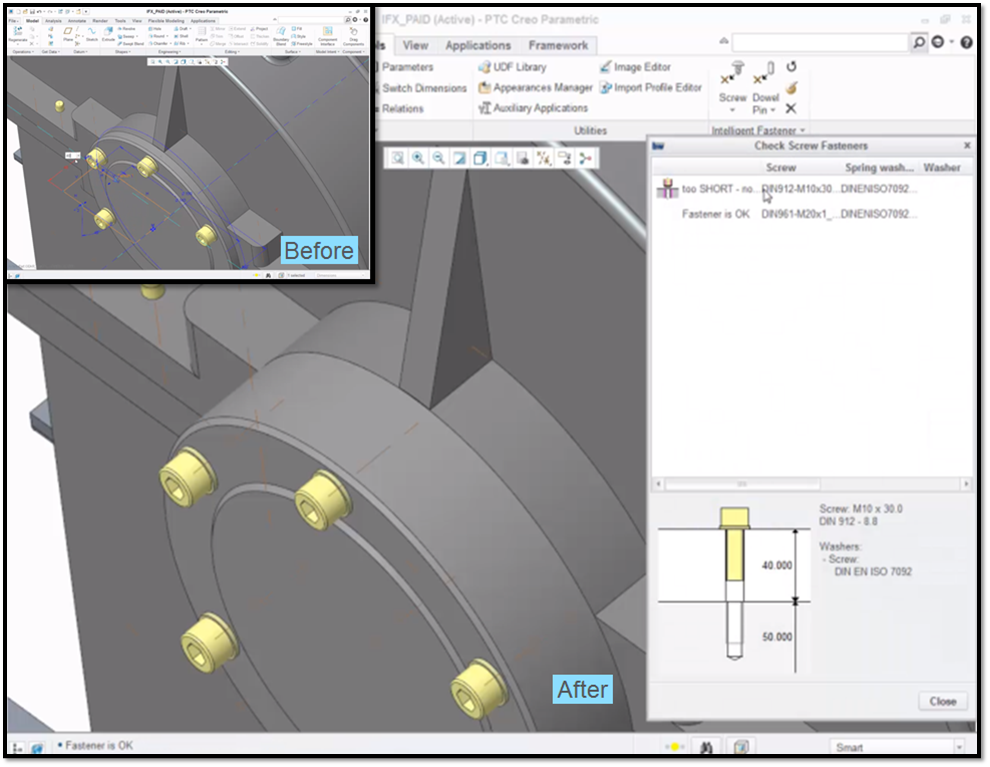

Designs often change. If your part changes thickness, you can make an update using the Check Screw Fasteners feature under Intelligent Fastener, within the Tools tab. IFX will check the length of all the fasteners and report back any fastener that is too short or too long. Using the report you can double click on any notification to open the Screw Fastener Definition dialogue box and update the screw length.

Here you can see that we changed the thickness of the cover from 10 to 40.

To learn more about the Intelligent Fastener Extension, check out our video tutorial (“Intelligent Fastener Extension”).

Stay tuned to our “Did You Know” blog series as we cover all of the exciting, new enhancements in PTC Creo 3.0.

For more in-depth product feature explanations, visit our Tech Tips area.

Have some ideas about what PTC Creo product features you’d like to learn more about? Send me a message or leave a comment below and we’ll write up the best ideas from the community. Thanks for reading, looking forward to all of your feedback!

In case you missed it, see what’s new and check out our recent Did You Know posts covering PTC Creo 3.0 enhancements:

- Did You Know? PTC Creo 3.0 Enhancements: Performing a Design Study in PTC Creo Simulate

- Did You Know? PTC Creo 3.0 Enhancements: Chamfer Support in PTC Creo Flexible Modeling Extension

- Fast Facts! Quick Tips for Using PTC Creo - Mechanism Part 2

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Nice overview about IFX. I will add a link to your blog post at the Intelligent Fastener Extension - IFX group.

Thanks.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks Oliver!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi

nice feature, long awaited.

Question, where does the library reside ? In a PDMLink context or it has to be on a windows drive such as a shared drive ?

Best regards

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Brianna

I have read the datasheet

There is a table listing the parts available in the library

are there actually only those ?

Screws mm & Inch DIN EN ISO 1207, 2009, 1580, 4762, 10642 DIN 84, 85, 580, 912, 921, 931, 933, 960, 961, 963, 6912, 7990, 7984, 7991 ISO 4014, 4017, 6914, 8765, 8676, EN 24017, EN ISO 1207 √ √ Washers mm & Inch Plain – wide & narrow Lock – regular & heavy √ √ Nuts, mm & Inch ISO 4032, 7040 Din 439, 934, 982, 1587 √ √ Dowels mm & Inch ISO 2388, 8734, 8735 √ Customization √ Screw configurations √ Support multiple fasteners of the same size but with differing sub information

This is quite thin compare to what Inventor provide for instance.

Any plan to provide a real comprehensive library ?

Thanks

Best regards

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Chris C,

we must differentiate between two libraries.

The fastener part library and the files for the IFX dialog (to fill the catalogs and so on)

- The fastener parts can be stored in PDMLink. If you assemble a fastener, it is loaded from PDMLink.

- The files for the IFX dialog must be on a local or a network drive.

Now to your second question about the library content. We think we have covered the most used fasteners for now.

At the moment we are planning to add more fasteners like CDS (3D Catalog Solutions for Industrial Suppliers : CDS | Catalog Data Solutions, Inc.) and some GB Standards.

But in the most cases the customers already have their fastener library and just want to include their library into IFX to assembly the own fasteners with IFX.

Which Standards are missing in your opinion?

Thanks

Oli