Community Tip - Want the oppurtunity to discuss enhancements to PTC products? Join a working group! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: [Drawings] Any tricks for sorting a repeat reg...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

[Drawings] Any tricks for sorting a repeat region with a comment cell?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

[Drawings] Any tricks for sorting a repeat region with a comment cell?

Just thought that somehow PTC would allow this. Anyone got ideas?

Thanks in advance. Pete

- Labels:

-

General

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Have a look into the doc posted here: Sorting Repeat Region Table by Parameters not Available in Table Column

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

That's a pretty good tip, but not exactly what I needed. Thank you for the tip tho! I will put it in my arsenal!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You can create a 'comment' for each component as a Component Parameter. This is created at the Assembly level and is not making any change to the components of the assembly. The values can be added via the Model tree. Unlike a repeat region comment cell, it will be preserved with the assembly

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

neat Idea. how do I make a COMPONENT parameter you are referring to?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

In the assembly, go to TOOLS - PARAMETER - COMPONENT, then select the part you want to add the component parameter to. You'll have to do this for each component within the assembly.

In the table, you'll add the column and add the report symbol &mbr.cparam.your-param-name

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Stephen Williams mentions one method - the other is to create a column in the model tree.

The trick is that there is a blank area at the bottom of the parameter selection window for model tree columns that you type the name of the parameter into - Creo won't show it in a list, at least it didn't in Creo 2. The first time you pick on that column for each component row it will prompt for the parameter type and then for the parameter value. Creating a mapkey to do the parameter type will help a lot. Once a component has a type and a value then you can edit it any time in the model tree and I think you can edit it directly in the repeat region. I think you cannot back-create a parameter from the repeat region; the assembly parameter for the component has to exist to be seen/modified within the resulting table.

The use I put it to was for setting the BOM item numbers, the epitome of sorting. This eliminated the need to FIX/UNFIX as components were added/removed and it allows skipping components that are needed to build the model, but aren't going to be part of the BOM (reference parts) It also meant that the item numbers were consistent across simplified reps. Lots of options available.

I prefer the family tree method because it's easy to march down the list.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Is there a way to use the component parameter in a note?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi,

repeat region parameters cannot be used outside repeat region, i.e. in a note.

Martin Hanák

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

He's looking for the component parameters as assigned in the assembly. I think they should be visible to drawing notes, but the online help gives no guidance on how to do so.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Aha ... missunderstanding...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

@dschenken wrote:

He's looking for the component parameters as assigned in the assembly. I think they should be visible to drawing notes, but the online help gives no guidance on how to do so.

He can use &<param_name>:FID_<feat_ID> notation, where <feat_ID> is component ID visible in Model Tree column named Feat ID.

Martin Hanák

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The component parameter can be show in a note per the following as stated by MartinHanak:

&<param_name>:FID_<feat_ID> notation, where <feat_ID> is component ID visible in Model Tree column named Feat ID.

I am looking at using a component parameter to drive the repeat region BOM Index as dschenken stated. I then can use the same component parameter" to use notes. Currently, this isn't possible with the rpt,index.

One thing I will be looking at is how to automatically create the BOM Index component parameter when each component is assembled. Any thoughts?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi,

define mapkey for component parameter creation and run it after finishing assembling process.

... or develop an application which provides requested functionality.

Martin Hanák

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello @pete3000

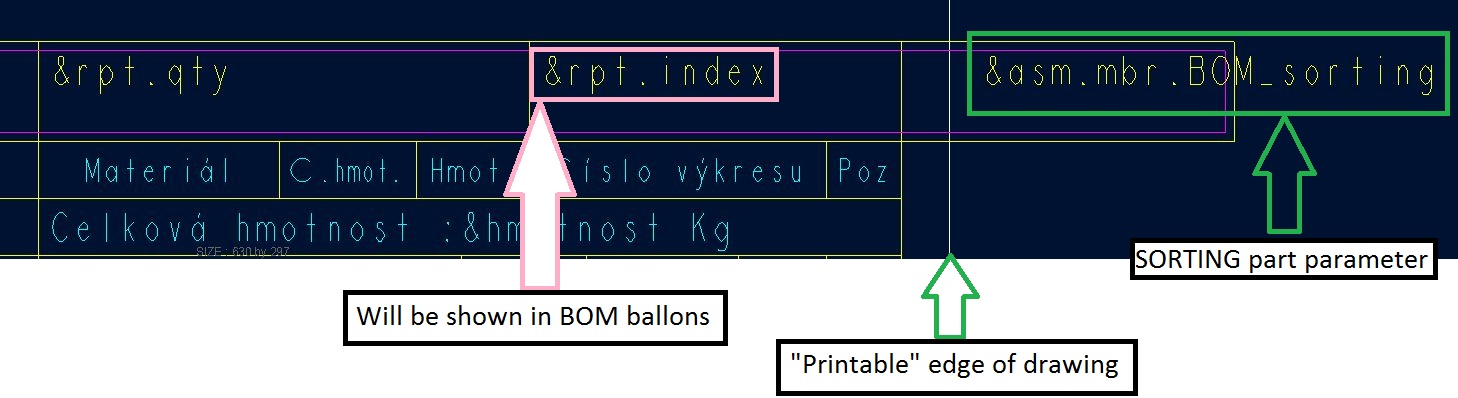

l will desribe you my praxis around sorting components in repeat region. See following picture:

BOM_sorting parameter located out of printable drawing space and some "numbering schema" is the magic trick. BOM_sorting parameter is included in each part and assembly. It´s only auxiliary parameter.

In result the table will be sorted by BOM_sorting descading:

- imported geometry - BOM_sorting import template value 90

- nuts - loaded from server - BOM_sorting value 70

- screws - loaded from server - BOM_sorting value 60

- sheetmetal parts - BOM_sorting from template - value 50

- solid parts - BOM_sorting from template - value 10

- assemblies - BOM_sorting from template value 1

- corner stamp -

BOM sorting:

1st rule BOM_sorting parameter

2nd rule drawing number parameter

Working progress in praxis:

- create assembly with many subassemblies, parts, screws etc.

- all assemblies are BOM_sorting value 1 - are at the bottom of table (change the value between 1 and 9 in order to rearange)

- all solid parts are BOM_sorting value 10 (are above assemblies and bellow sheetmetal parts) ordered via 2nd rule drawing number - change BOM_sorting value between 10 and 49 in order to rearange

- all sheetmetal parts .... the same like solid parts ...

- etc. etc.

Advantige of this method:

- more different components can be the same BOM_sorting value ---> &rpt.index is shown in BOM ballons and it´s unique for each part ---> each BOM ballon value will be unique

Disadvantiges of this method:

- do not use annotations like: "weld position 5 and 8 together" ---> position value can be changed without your "wisdom" (added or deleted parts) and your annotation will be confusing

Hope it can helps

Regards @mbonka