Community Tip - Your Friends List is a way to easily have access to the community members that you interact with the most! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Drawings unstable in Creo 2.0?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Drawings unstable in Creo 2.0?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Drawings unstable in Creo 2.0?

I just completed a very comprehensive machining drawing and I must say that between 2000i and Creo 2.0, the drawing had become seriously unstable.

1st I was dealing with some very annoying graphics artifacts. Ones where simply moving an annotation feature would blank out the feature. More often than not, I would have to regenerate the drawing to get things to unhighlight or come back to a visible state. Seriously annoying indeed!

Then I had whole blocks of dimensions and other features just -move-. They jumbled themselves up left and right generally undoing a lot of careful placement that I was -doing-. It happened sometime between switching to the model and drawing, and poof, I again had to fix a couple of dozen annotation features.

Am I the only one? ...or is this something that has become the norm? Seriously, in 2000i, it was set it and forget it. Now I don't know how people keep from pulling their hair out.

I am on an approved platform with the approved drivers... etc.

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Labels:

-

General

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

If I needed one day to create one drawing then I would end up drinking only salt water.

I am just kidding. ![]() Great job Antonius. It's hard to figure out all the how-tos with Creo.

Great job Antonius. It's hard to figure out all the how-tos with Creo.

I don't know the requirements for your drawings. Can't think of anything so horribly complicated so it would take one day to create. Maybe some sort of huge assembly with lots of explode states.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Highly featured machine parts with lots of little details all controlled with GD&T.

It's an exercise of moving data around and adding detail views to make sure everything is crystal clear to the machinist. The challenge always comes in when you just have to add one more dimension or feature control symbol and there is no clean place to put it in an existing view.

The other side of the coin is having to manage the design control while making the drawing. So the effort is pretty much 50% design work and 50% detailing.

For some reason, the tolerances I apply to my sketch dimensions do not transport to the drawing when showing their annotation in drawings. I need to work with this more, but somehow I thought that would work.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Maybe we covered this previously... as I said this thread is a killer. It took on a life of its own. So if I'm asking a dumb question I apologize.

My question is this: if you're making highly featured machined parts and have to make them crystal clear to the machinist, I'd ask "why"? As in... why do the features need to be so crystal clear to the machinist... is it for inspection purposes or MACHINING purposes?

What I'm getting at is this... whenever we have a machine shop that requires 15,000 pages of documentation for a part, we know something's amiss. Usually we just send off a Pro/E file or a STEP file and the part comes back with a first article inspection in a week or so. If we have special inspection dimensions or GD&T, the first article notes these and demonstrates that the part we've received has passed inspection and meets our tolerances. The only shops that struggle to do this are the ones using drawings rather than solid models.

So I guess what I'm asking is... is your machinist working "old school" and is this contributing to the problem? This doesn't excuse the problems you had making a fully detailed drawing and it shouldn't let PTC off the hook. I guess I'm just trying to understand why the drawings are so critical to the machinist?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I understand the question, Brian and I had not expanded on this line of thinking.

In general, I can throw a sheetmetal design on a shop and I always get what I want because is design to general shop tolerances. No issues. Just let them know the material, how to finish it and what fasteners to use.

Since there are no standard shop tolerances for turned and milled parts, you need something to go by when inspecting parts. I work with many shops that can do runout precision to .0001" and often require certified compliance. These shops get paid very well so you can understand when a batch of parts get rejected. Someone is going to be pointing fingers. Therefore, the drawing satisfies the "legal" requirement.

And technically, the ASME Y14.41 will hold up to legal scrutiny. What the last supplier I talked to told me is that they are not investing in all the various CAD systems and terminals for the inspection teams. The shop floor too wants paper in hand. Again, yes, Y14.41 will cover this... but they are not interested (and I mean adamantly!). These are some of the best shops in the pacific northwest.

I can also say that I've worked with a couple of dozen mechanical engineers worth their salt that have no clue what ASME Y14.41 even is. I can just see forcing them to make a compliant model. Their productivity would drop to zero. I would love to land a contract using model annotation as required output. Then this thread would grow exponentially! And my tech support count would follow ![]()

I am glad that this thread has grown so many tentacles. At least it is all in one place.

And yes, Creo 2.0 is still unstable. I have all kind of weird things happen out of the blue. My command finder completely ignored me last night. Had the system crash on a Revolve diameter change (I think is choked when I had a "Global Interference" open in another window). When I rebooted Creo, it changed the diameter just fine. I also had GTOL move around on the drawing when I supressed a completely unrealted feature in the model.

By the time your team moves up to Creo 2. ...6 or so, most of this will be ironed out. ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

By the time your team moves up to Creo 2. ...6 or so, most of this will be ironed out.

Yeah, unfortunately, this is very true. I've never been able to work on the bleeding edge of PTC software because I've always worked for companies that needed stability. When I worked at Amp Incorporated in the early 90's, for a time we had one of the largest installations of Pro/E in the world at 900+ seats. Even then, we were always a rev back because each new revision brought enhancements... but also uncertainty.

Now, twenty years later, I'm jumping through hoops to get my people onto Creo 1.0 because we just can't go to 2.0 yet. I read either on a thread here or on one of the PTC/User email exploders a message from a PTC rep stating "there's no reason not to go directly to Creo 2.0 immediately". When I read that... I cringed.

I've said numerous times that I feel a shift in the way PTC is dealing with customers, handling problems, and honestly trying to hear constructive criticism to better their products and services. I truly believe this to be the case. However, when I hear a statement that "there's no reason not go directly to Creo 2.0 immediately", it brings back memories of the "bad old days" when PTC seemed tone deaf and clueless about the software's shortcomings.

I'm glad we're making progress... but someone hasn't gotten the memo that we're supposed to be starting a new period of honesty and transparency with customers. Honesty means saying "Hey, Creo 2 is amazing for several reasons... and we're working to iron out some problems first adopters have discovered".

Thanks for working through these problems Antonius... it's early adopters like you that help vet the software and iron out the problems for the rest of us.

Take care...

-Brian

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Ah... glad I kept readin the thread! I took screenshots to show where the Hatch/Fill command was. Turns out that's such an old topic now that we've moved on to other things!

If you don't stay up to date, things move in this thread!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Now, twenty years later, I'm jumping through hoops to get my people onto Creo 1.0 because we just can't go to 2.0 yet. I read either on a thread here or on one of the PTC/User email exploders a message from a PTC rep stating "there's no reason not to go directly to Creo 2.0 immediately". When I read that... I cringed.

I would not hold my breath while reading that statement. The new interface that came out with Creo 1.0 is poorly implemented to Creo Parametric 1.0 and causes serious performance issues. The lag is just enormous.

These problems get fixed in Creo 2.0.

For me going from Creo Parametric 1.0 M030 to Creo Parametric 2.0 F000 was a total rescue.

I guess PTC was already aware of these issues thats why they came up with the Quality Agent while releasing Creo 1.0.

Creo Parametric 1.0 isn't much different from Creo Elements\Pro 5.0. So switching just to that might not be worth the hassle.

In Creo Parametric 2.0 there are many more usable enhancements but that surely is matter of personal preference.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

One other thing I noticed when changing default font characteristics in drawings:

Detail options (.dtl):

default_font <filename>.ndx

text_thickness <numeric value>

def_view_text_thickness <numeric value>

That last one defines all the view names where the thickness in its associated properties are unchecked and therefore does not follow the default "text_thickness" setting. You have to know to set the "def_view_text_thickness" option.

Adding the option "def_view_text_thickness" does not update view labels already defined although, fortunately, you can do this by changing the view name properties - text style and checking the default thickness option.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Antonius Dirriwachter wrote:

It's an exercise of moving data around and adding detail views to make sure everything is crystal clear to the machinist. The challenge always comes in when you just have to add one more dimension or feature control symbol and there is no clean place to put it in an existing view.

Yeap. These situations are so common with drawings. Luckily it's not so much pain to move bunch of ordinate dims with jogs in Creo Parametric 2.0. It used to be alot harder in Creo 1.0.

Thanks for the insight.

Antonius Dirriwachter wrote:

For some reason, the tolerances I apply to my sketch dimensions do not transport to the drawing when showing their annotation in drawings. I need to work with this more, but somehow I thought that would work.

How about datum curves or curves from intersect, copy or offset features?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Jakub Fojtik wrote:

...Antonius Dirriwachter wrote:

For some reason, the tolerances I apply to my sketch dimensions do not transport to the drawing when showing their annotation in drawings. I need to work with this more, but somehow I thought that would work.How about datum curves or curves from intersect, copy or offset features?

Oh, it has nothing to do with the geometry. I had edited some sketch dimensions to reflect their critical tolerances in the part file and expected them to be retained when shown in the drawing. When I showed the model dimension in the drawing, the tolerances seemed to just go back to the default tolerances.

I am always looking for passing along engineering data to the "drafter". I suppose that Annotation will be the only way to do this reliably. It is not a current requirement, I just thought this behavior was limiting.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

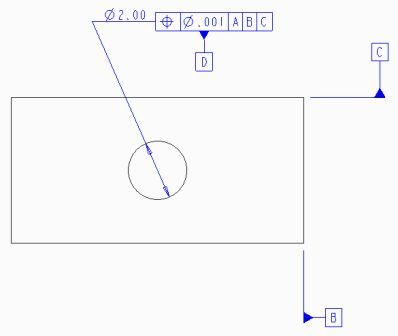

Antonius, I feel your pain. To me, GD&T in Pro/e has always been a total pain in the dingoes kidneys ( ![]() ). What I did was create a symbol to allow me to show the "plunger-style" (hate the new standard) datum.wherever I want. Now, keep in mind it's a symbol, and as such is not parametric, but it works well. You can attach it "o entity" on a dimension leader line, or do a tangent or normal leader, and has variable text (as you can see I cna make as many datum "A" symbols as I want since it's not tied to an actual datum. I made th esymbol text size dependent for our .15625" text, but you can modify it if needed. Give it a try and let me know what you think.

). What I did was create a symbol to allow me to show the "plunger-style" (hate the new standard) datum.wherever I want. Now, keep in mind it's a symbol, and as such is not parametric, but it works well. You can attach it "o entity" on a dimension leader line, or do a tangent or normal leader, and has variable text (as you can see I cna make as many datum "A" symbols as I want since it's not tied to an actual datum. I made th esymbol text size dependent for our .15625" text, but you can modify it if needed. Give it a try and let me know what you think.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yep... this is what I was suggesting.

This thread has gotten away from me. I have to respond to several people but it's easiest to jump in here! Thanks for the symbol Frank.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Ha! Now all I have to do is figure out how to make symbols ![]()

Appropriate use for the datum tag is to hang it from your GD&T feature control symbols when available. Since I make GTOL from notes (@[ etc @]) I don't think this work using the "move to GTOL" feature of the datum tags and you can't just hang the triangle in space (or can you?). If I made the symbol, I would probably only make the triangle with a tail and "float" a text string note for the datum itself.

(I can just see PTC developers turning in their graves with these comments ![]() ).

).

I was drawing sketched lines to make draft datums. Sometimes the datums would remain attached to the drafting sketch lines and other times if would not (when moving views, for instance). The line would move with the view and only sometimes would the datums move with. The creation of draft datums has a really weird pick sequence. I use the lines for reference and I could not get a consistent "click pattern" to get it to prompt for the datum name.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I've looked at trying to get a draft datum to attach to a FCF and some success although it doesn't show up exactly like in the examples seen but I can't say there is anything wrong with the format. I can post what i tried if you like so you can try it since my attemps were in Creo 1. I also found more examples of datum symbols with tails and don't think it has anything to do with angled surfaces but leader attachment. This makes sense looking at notes. Although a straight line is preferred there's nothing wrong with using a tail. All the examples I see seem to be for consistency. Tails aren't used on vertical datums but are on horizontal or angled datums and it seems to be because leaders are left or right oriented. So for consistency tails are used so all datum symbols have leaders attached to the left or right.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I would like to see what you came up with. Remember that my FCF are notes, not GTOL. To use GTOL for FCF, you must define model datums so they can be assigned in GTOL.

You are right that tails are allowed in the 1994 ANSI/ASME Y14.5, as are hollow (open) triangles (found that option for detail.dtl tonight). It is a problem when your customer defines the requirements. Fortunately, draft datums do make leaderless horizontal datum tags.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

A couple of new observations:

Yes you can use draft datums in GTOL. YEA! Creo didn't crash manipulating draft datums either.

And how do you "properly" remove a break from a leader?

Drafting sketches are a real pain. I found the setting where constraints will show but overall, if you lock things to Parametric Sketch, you can't seem to do anything "real" with them. No dimensioning, no deleting constraints, no nothing. Anyone have a great (not just good) -GREAT- tutorial on drafting sketches?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I'll take some images add some directions so you can see how it compares.

As for the datum symbol with a tail I certainly understand the customer preferences and requirements rule I was just giving you some more information as to why I think it's included in the standand and how it's used. I found a GDT book were the author had no datum symbols with leader lines from the top or bottom of the square they all came from the left or right. So any horizontal, angled, or diameter (not in profile view) had a datum with a leader line coming from the left or right.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I use Lowell Foster's 1994 Geo-Metrics III. I wish they published the 2009 version in the same format.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Well, here is what it looks like.

I found a couple of useful things along the way that may help if you decide to use or try it. I found two ways to create it. The first is to create the FCF, attach the draft datum, and then attach the FCF to a dimension using the dimension elbow option. The other is to add the FCF without the datum symbol to the dimension using the dimension elbow option and then add the datum symbol. If you add the FCF using the dimension option Creo will tell you you need to attach the datum symbol to a dimension which for a draft datum isn't an option.

I also got the draft datum selection to work consistently for the on entity selection. I took a look at the messages to see what was happening and found Creo considered my point selections as coinsident. I haven't figured out exactly what I did to get two other options that worked. I hit some key and/or mouse combination that moved me through the dialog but can't get it to work consistently. Anyway the consistent way I found is to select the selection items pick box to activate it. Select the edge you want the draft datum on and select OK on the dialog box or MMB to define the start point. Next, use RMB to get a menu that will allow you to pick the second reference so you can pick a point for the end point and select OK or MMB. The next thing you should see pop up is the name dialog for the datum.

I keep hearing mouse clicks have been reduced but some of the very basic ones that are used daily have added at least one or two. Maybe it's because I don't use mapkeys much or took the time to customize but this operation added three clicks to what was select point, select point, enter name in WF5.

NEW TRY:

Looking at it again I found the mouse selection: pick box in dialog, LMB on entity, MMB for start point, move mouse to to new point on same entity then RMB, LMB on entity, MMB to select second point. If all goes well you should get the datum name box.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks, I still can't find the prompts for the selections so I am totally lost... but I was having some luck with a double-click. Go figure.

Today I learned that if there is a model in the drawing, you can't use drafting datums for GTOL frames with datum references.

I gave in and defined a few model datums and sure enough, I now have a big fat ugly datum plane stuck in my models that won't go away (cylindrical parts needing a vertical reference). I defined all the datums in the drawing and attached them to FCF and dimensions like they were suppose to be.

I also defined the GTOL FCF and strung them on faces. Unfortunately I cannot force a gap on the tangent leader nor add a break in the leader. Again, what a pain!

Then I tried moving the datum tag attached to the FCF and a datum tag pops up all the way on the other side of the part in green. It wouldn't let me move it and things just went "wierd" so I detached it from the FCF and started over. It was totally freakin' confused because the FCF also had "shadows" on other parts of the print.

To date, and with the ASME Y14.5 1994, Creo 2.0 has got to be the absolute WORST software I've used to date with regard to adding GTOL to drawings. It is -SO- buggy that someone needs to go back to the drawing board {pun intended}. No one, and I mean NO ONE at PTC could have ever signed off on this if they actually tested it.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Don't know if it's a factor or not but for the FCF you need to set the Model pick list selection to The Drawing on the Model Refs tab of the GTOL dialog. This will allow you to assign draft datums as datum references in the FCF. Another note is there is no limit to number of draft datums with the same name (I didn't think of it because I usually use model datums which means the FCF also needs to be stored with the model to use model datums). I had to drag the message area that is at the bottom up to see the prompts.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I did try the draft FCF verses model. It got quite maddening to keep them straight.

The prompt line needing more lines is kind of silly. I had noted this before. Your tip about the MMB was the missing link.

A little more playing with it last night noted that the draft datum planes, when attached to daft entities, are parametric. To maintain this parametric relationship, you cannot manipulate the draft datum (or at least very restricted) or the datum disassociates from the entity and gets "stuck" to the page.

...and ![]() you can't change the text style of surface finishes! No thickness and no font options. Back to faking it.

you can't change the text style of surface finishes! No thickness and no font options. Back to faking it.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You can hang the symbol I made from a Feature Control Frame (FCF) as well. Funny, I can't see the symbol attachment. Were you guys able to get dowmload it?

If not, here it is again.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Ingenious!

Care to start a document on how you did that?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Patriot_1776 definitely an ace Antonius... but he tends to fly below the radar (unless there's a thread debating the ribbon menus ![]() )

)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hah! And on the ribbon debates, I'm like the "chaff" deployed by aircraft to fool RF-guided missiles! ![]()

Thanks guys, I've wanted to do that for a long time, and finally when we started using the '94 ASME spec with those Godawful "plunger" datums I finally made a symbol. It seems to work pretty well. Now I cna add datums wherever I want with no hassle.

In fact, what I'd really like to do, is create an entire library of non-parametric or semi-parametric symbols to replace the standard GD&T since it's such a pain to use. I did this in the mid-'80's in AutoCAD, no reason why I couldn't do it for Pro/E. ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You could have a 3rd party opportunity there, Frank.

I remember the days of Cadkey when GD&T simply wasn't possible and a 3rd party jumped in and saved the day (DraftPak). Cadkey endorsed it and finally made it their own. Maybe PTC needs this kind of boost to make their software something it was never meant to be (usable for lowly drafters). [be nice, I still use Cadkey '99!)

The only other symbol I can think of at the moment is composite FCF in non-GTOL mode. I will have to see if it allows building frames with @[ in the symbol.

I admit, I was up pretty late reverse engineering your symbol. How did you know to use the "\" delimiters for the variable? Documentation didn't have anything even remotely proved helpful.

Now I can make my surface finish symbols since surface finish bundle doesn't have changeable fonts.

Thanks again, Frank. This is where the forum outshines Tech Support by legions!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This about the only place variable text is explained.

About Variable Text Parameters

If you insert text notes with a backslash before and after them (for example \notetext\ ) in the symbol definition, these notes become "variable text" notes. They appear in the Var Text tab of the Symbol Definition Attributes dialog box. Variable text means that you may enter a selection of values in the preset values text box for each variable text note. For example, if your note had the text

"Drafter Name \names\,"

"names" would appear in the left window of the Var Text tab. You could enter a list of employees names in the right side area to select from when the instance is placed. When you place the instance, you can select a name to follow "Drafter Name" from a drop down list in the Custom Symbol dialog box. (Select the symbol and click Properties on the right mouse button shortcut menu to show the dialog box.)

You may also enter a parameter as the preset value for the variable text, for example "&draftername". If there is a "draftername" parameter in the drawing, the symbol note will return its value.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Antonius...

Kevin's blurb above about variable text is, as he says, about the best there is. However in the older Pro/E manuals there was a pretty good explanation. I learned to use them long ago so I already knew about them. Perhaps you could make a nice new document explaining them so we can have it here on Planet PTC for the future.

Even though the blurb Kevin posted is accurate, it's not very readable and it lacks pictures. Maybe someone could jump in and make us a nice doc?

Thanks!

-Brian

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

If I wasn't so busy cursing the software, I might have time to do just that. (...he says sheepishly)

I still have some of the old books too from PT-Modeler (remember that?). I still use those as well.

Today: Exploded views... What the HEY!!! I do an exploded assembly and the dialog is so criptic I almost gave up... and once I had it, with a few trace lines, I couldn't figure out how to save it. Speaking of a dialog that needs a comprehensive overhaul!

Then I get to the drawing, and since I hadn't saved the one in the assembly, I did it -again-! This time on the detailing dialog... and lo! this is the old 2000i interface. Oh, what a joke... cruel joke no less.

I got through it and next time it will be easier. But Y'oh ...what a horrible interface!

I did notice something that also came from the past... 2000i era indeed: the symbol creation dialog still had the old "Environment" button... same dialog and everything! Seriously, we have a mish-mash of 3 totally different interfaces at work here. Very poor execution indeed.