Community Tip - Stay updated on what is happening on the PTC Community by subscribing to PTC Community Announcements. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Easiest way to use a centreline when...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Easiest way to use a centreline when...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Easiest way to use a centreline when...

I'm having terribly difficulty understanding how I can create a centerline on a surface so that sketches and extrudes cutouts can be made "in the middle".

Maybe my starting point was wrong? This is what I've done:

- I've created a sold part by sketching the "base" to be 110mm wide by 300mm deep. My CSYS is the front left point.

- I've then extruded that sketch to be 45mm tall, so now my CSYS is at the bottom front left of the case.

- I now want to sketch some cutouts on the front of the case, and these are to be centered (so the mid point of these cutouts is 55mm offset from the origin of my CSYS on the X axis).

Now of course I can create a vertical centreline that's 55mm offset, but the issue is that if ever I change the original width of the case (first sketch that was then extruded), I have to change my centreline.

Is there not a way to create a centreline on a surface so if the dimensions of that surface change over time, so too will the position of the centreline?

Would I be better off moving my whole model so that the CSYS is in the middle of the front face on the X-axis? Or create a secondary set of coordinates and use that as the reference point for the sketches on the front surface?

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

Solved! Go to Solution.

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Xavier...

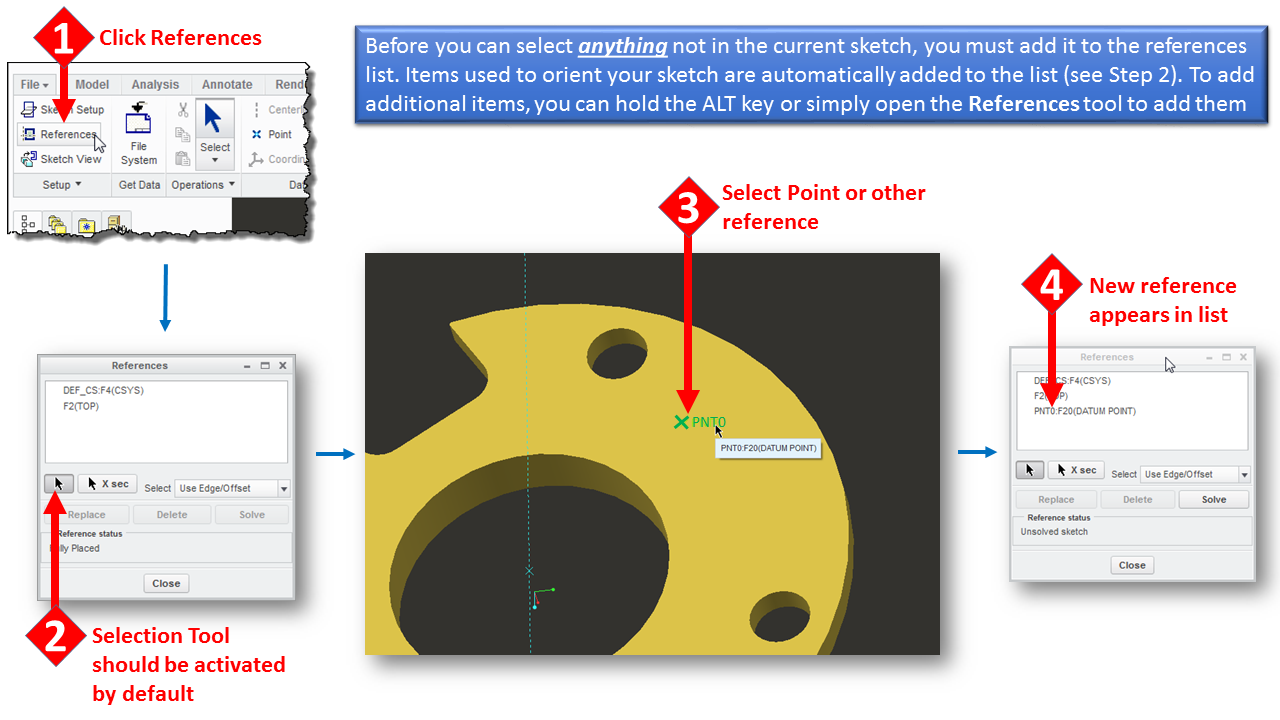

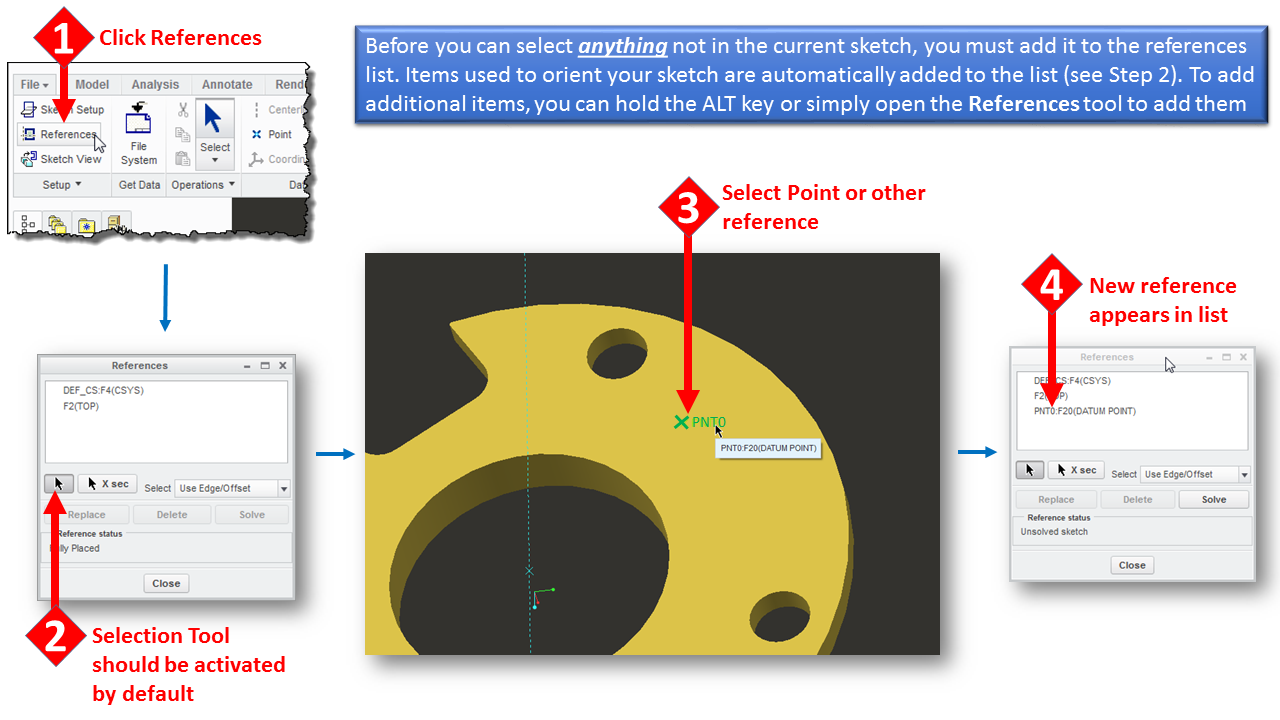

It's also selectable without the ALT key. You just have to add it to the references list before you can select it. This goes for any reference not in the current sketch. Hitting the ALT key is just a shortcut to add a new reference to your list of available references.

Select the slide below to view a larger version (easier to read).

I just didn't want you to get hung up on the ALT key. It's just a shortcut to save time. There are other ways to add references.

Thanks...

-Brian

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

In your primary sketch, you can create a geometry centerline rather than a construction centerline (the centerline on the left of the ribbon). I call these datum axes centerlines because they create a datum axis for selection once the sketch is complete. Same goes for points and CSYS'.

You can constrain this centerline in the sketch in one of many ways so it always stays centered. In subsequent sketches, you can now reference this axis created in the subsequent sketch.

Hope this all makes sense. Give it a try and see if this doesn't work for you. Of course, I am assuming you are on Creo 2.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

If you only want the centerline in one sketch, you can do this with assigning an equal constraint to two dimensions...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

As they say, if you ask 10 different people, you'll get 10 different answers for something like this, AND on top of that, I would do it different ways depending on what features I think I will modify later. So this is just another idea. But I will say drawing the X inside the rectangle seems time consuming.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Many times the answer depends on how things might change.

For example, if there is the intial cutout, followed by other, related cutouts/markings.

Some methods can better handle:

1) Moving all the cutouts to a different face

2) Moving later cutouts to a different face, but leaving the first one in place

3) Moving the first cutout to a different face, but leaving the rest centered up

4) Not being centered anymore

5) Being turned 90 degrees or some other angle

6) Someone changes the angle of the face

7) The face is no longer flat

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Matt Griswold wrote:

...But I will say drawing the X inside the rectangle seems time consuming.

That is a built-in function in the Creo 2 sketcher (down arrow option in the rectangle tile).

But yes, I too would do it a different way in most cases. I like the "equal dimension constraint" trick though.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

sweet! I didn't even realize it. I use centerlines for tons of things, though. And sometimes construction lines, all depends. And I mirror a lot (in sketch). But I also keep my sketches simple shapes most of the time, seems easier to manage in the long run.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I like to keep sketches simple ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

lol....yeah, about that...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Back in front of the PC now.

Thanks AD, but I can't seem to do that: drawing a the axis I want (vertically aligned to the centre of the front face) isn't in my initial sketch, it's orthogonal to it. My initial sketch is the base on the X-Z plane. So whilst I can certainly pick the mid point of the bottom line as looking from above (so the front plane of the case), I then need the centreline axis along the Y-axis. I've started with the base of the case and extruded "up". Had I started with the front of the case (first sketch) and extruded "back" / the depth, then I'd be fine.

I would have thought it to be logical that when you select a surface on which you want to sketch, the sketcher automatically allows you to easily reference the edges of the surface: why would I want to sketch something outside / beyond the edge of a surface?

It must be pretty obvious that I'm new to Creo (yes, using version 2), and whilst some things are great, other things seem so backwards and counterintuitive that I just can't figure it out for myself.

My previous CADing has been with AutoCAD, although that was primarily 2D drawings only (wiring diagrams, etc). My initial 3D modelling was with Sketchup, but I've now moved to a "proper" package although it has more than vertical learning curves at times (pun not really intended)!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Understood. Yes, even in the original protrusion, you can put a section geometry point in the sketch and when extruded, the point will generate a datum axis for subsequent references. Just a little tip ![]()

You have a steep learning curve ahead of you. As already stated, there are at least a dozen ways to skin this cat. Of course, remember that no question is a dumb question and we expect to see you here often ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The quickest way is to create a datum point on the edge and set it to .50 ratio. Then reference that in your sketches.

An alternative is to add a measurement from one face to another and create a parameter using that measurement; locate the centerline with a dimension set equal to half the measurement.

Another alternative is to create the original part symmetric about the default datums.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks David. I already tried making data points, but when I try that, they are created outside of the sketch and then not accessible within the sketch, even when I place them before.

As soon as I enter sketching on the surface, I can no longer reference / select the edges of the surface.

I'll have another look when I get back in front of the PC.

Thanks again

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

They are selectable as sketch references.

Or you can select the align function and Pick from List to get the point.

70% guess - formerly used Solidworks? Only guessing as the number one complaint from SW users is not having open season easy selection of existing geometry in PTC's Sketcher Intent Manager.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Ahhh. At last. Success. ![]()

What I was missing was the magic of the Alt key! I didn't know that I had to hold down Alt to be able to select a datum point created elsewhere. With it selected, I can then create a sketching centreline and align stuff against it.

Changing the width of the original sketch then updates the position of the centreline and any cutouts referenced by it, so my central cutouts remain in the middle when I change the width.

Another thing I've discovered: making the bar at the bottom a little taller reveals helpful messages. The number of times I would should "Why?!" will hopefully diminish now I can actually see what it's complaining about. Strange that this isn't raised by default to help newcomers. It's easy to hide something you don't want to see (for experienced users who want to maximise screen real estate), but far more difficult to see stuff that's hidden if you don't know it's originally there!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The typical workflow when starting your sketch is to pick your references. Based on your comment of "datum point created elsewhere" it seems like you are skipping this step? Because the references box should let you pick almost anything.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Matt,

I was referring to a datum point created in another sketch (the 1st sketch from which the extrusion was made). So in the model tree, the reference I want to use is from another branch if that makes sense.

It's perfectly selectable, providing you know to hit the alt key! - something I wasn't aware of.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

AH, ok I got you. yeah I use mostly external references and just hide them if looks messy on screen, but then I can usually scan through the model tree quicker to modify things when needed. Especially if I rename them.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Xavier...

It's also selectable without the ALT key. You just have to add it to the references list before you can select it. This goes for any reference not in the current sketch. Hitting the ALT key is just a shortcut to add a new reference to your list of available references.

Select the slide below to view a larger version (easier to read).

I just didn't want you to get hung up on the ALT key. It's just a shortcut to save time. There are other ways to add references.

Thanks...

-Brian

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Xavier...

I wanted to throw out one last option that always gets overlooked. You can create your centered cut without any additional points or datums by making use of known dimensions. I've created a few slides to illustrate how this works...

Click on any of these images to see a larger view. The idea is to add a dimension to your sketch which references geometry already existing.... then use that dimension in a relation to control the position of your new feature. See below...

While the other techniques you've found here are certainly valid, this one gets overlooked and it's very useful. Back before Wildfire 2, you could easily create a known dimension, but once the explicit option to do so was removed from the user interface, people seemed to forget it was possible. I just wanted to remind everyone.

Good luck!

Thanks...

-Brian

Message was edited by: Brian Martin Attached the model used for the slides for reference.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks Brian for those invaluable pieces of information. Would those slides be part of a wider guide that's publicly available? It looks like it's right up my street for the level and kind of information that I'm finding really useful.

Quick community forum question: can one no longer mark answers as helpful once a single answer has been marked as correct? I've "un-corrected" my earlier post (detailing the use of the alt key) and put your first reply as the "correct" one, but cannot add your second post as helpful (even after I had the marked the topic as unanswered). ![]() I would have thought that the ability to mark posts as helpful, would be, well, helpful especially as there can be several posts that all contribute to the "correct" answer... And I guess that can then help others find the answers to previously asked questions quicker!

I would have thought that the ability to mark posts as helpful, would be, well, helpful especially as there can be several posts that all contribute to the "correct" answer... And I guess that can then help others find the answers to previously asked questions quicker!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Relations are a very power tool and are used at many levels. However, I try to use them as a last resort at the sketch level. It is too easy to build in a relation that requires two regenerations to complete at all levels. -If- I can resolve a sketch with design intent using geometry, I will do this before considering relations at this level.

Having said that, building relations at feature level or part level is more reliable. there are times when a part is considered fully regenerated where the provided information is actually out of date. If the system considers the regeneration complete, it will not attempt to complete those things not up to date.

The easiest way to create such a failure is to use section relations (such as values or calculations) in model annotation.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Sorry to drag this back up, but I'm having a similar issue now using Creo 3.0.

I essentially want to add a new cooridnate systems to a 6.3mm Faston part (taken from here).

One ref on the flat plate (mating connector), a second centered on the disc surface on the cable side.

Maybe the part I've imported prevents me from doing this? But no matter what I try, I cannot get it working. It looks like the menus are slightly different too, maybe I'm not using the correct "Reference" menu? ![]()