Community Tip - Learn all about PTC Community Badges. Engage with PTC and see how many you can earn! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: How can I create a helically swept S shaped fl...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

How can I create a helically swept S shaped flute?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

How can I create a helically swept S shaped flute?

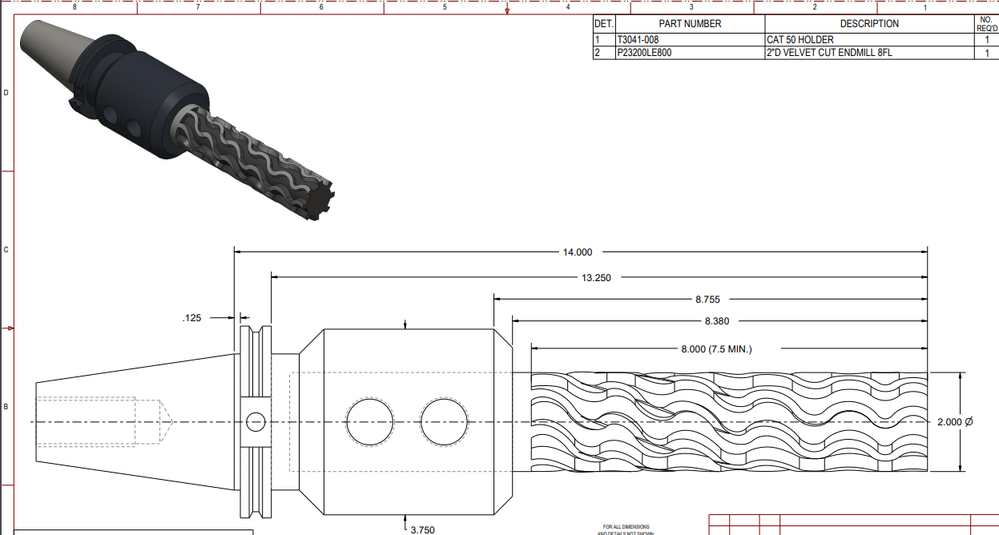

I am trying to recreate a velvet endmill, and frankly, I have no clue where to start with modeling this. Usually, I use a helical sweep to model normal endmills, but this has me stumped.

Solved! Go to Solution.

- Labels:

-

Rendering

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Interesting, never seen one of these.

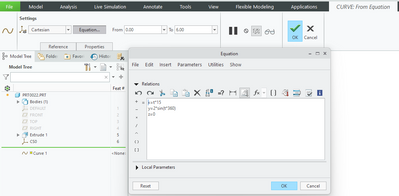

Off the top of my head, the variable section sweep using of trajpar equation involving (co)sine is the go-to for these kinds of "periodic" features.

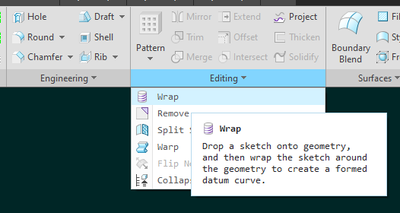

But maybe the "wrap" tool could be used to get the snaking curve to follow the helical path around your stock cylinder?

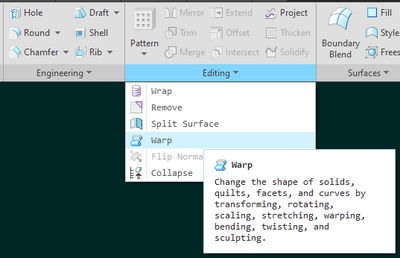

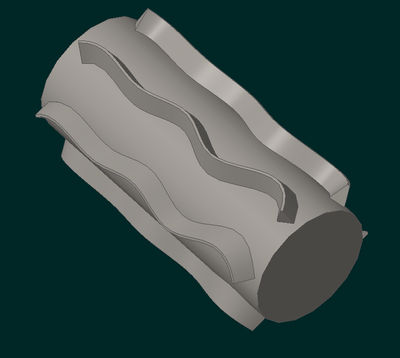

The other way would be to make a "straight" protrusion (with undulating sides), pattern, then twist using the "warp" feature:

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Interesting, never seen one of these.

Off the top of my head, the variable section sweep using of trajpar equation involving (co)sine is the go-to for these kinds of "periodic" features.

But maybe the "wrap" tool could be used to get the snaking curve to follow the helical path around your stock cylinder?

The other way would be to make a "straight" protrusion (with undulating sides), pattern, then twist using the "warp" feature:

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

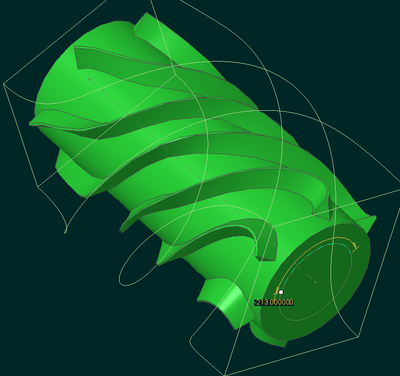

Ah. That's why I mentioned whether you need it just for looks, or for accuracy, and that would determine methods needed. Warp is excellent for things like this because it's actually very good at, well, "warping" geometry, in that it pretty much will not fail. The downside is that you can't really control it, and you get what you get. You can see that from the fact that at the distal end (from the chuck) that the twist is basically zero. It's been a long time since I played with Warp (since I find it basically just a toy for my uses), but I think to correct that you can make that "bounding box" that's used to affect the geometry, be off the end of the part so that the twist actually affects even that end. OR, make it longer than you need, and cut it off before the twisting stops. I could be wrong, but I thought that was what I'd done years ago, the last time I played with it.

I guess what I'm surprised at the most is that they are finishing cutters. I would have thought, from the similarity to the roughing cutter pic I posted, that they were a new roughing tool. I've seen a lot of cutters in my time, but that's a new one on me. Gonna have to look them up.

Glad you got what you needed here, and best of luck!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Ok, so, you piqued my interest, and so I called them:

End Mills | Milling Tools | Cutting Tools Manufacturer (regalcuttingtools.com)

So, they don't make them anymore (cost), but it's what he called a "roughing finisher". So, basically nowadays as a machinist you're either hogging material out absolutely as fast as you can, or you're finishing, nothing in between. What these do is remove material faster than a straight-edged fluted tool, but not as fast as the "corncob" (his term) tool I showed, but it gives a better finish than the corncob tool, but obviously not as good as a dedicated high-flute-count finishing tool. So, I guess they'd do a roughing pass (or 2) with a dedicated roughing tool, do a pass (or 2) with this, then do an actual finishing pass (or 2) IF needed. If no actual finishing passes, you still had a better surface finish than with a corncob tool. He also said that, as I surmised, the "scalloped" edges cut the chips up, also as I surmised that being good for "gummy" materials like stainless that usually produce long stringy chips that bind up and break tools and ruin part finishes. ALSO, he said that all of these edges were NOT the same from one flute to the next, that the trough of one of the scallops would be finished by the crest of the scallop on the successive flute. In other words, to make things even more difficult to model (as if it isn't already?), that, say, for a 4 flute cutter, you'd have to model one flute, pattern that 180deg, then 90deg from that, go to the complementary flute pattern, then pattern THAT 180deg to get all 4 flutes. To be correct, you can't just model one flute and pattern that 4 times at 90deg.

Very interesting. IF I actually had time (LOL - NOT!) I'd like to model one just for fun....

Anyways, thought I'd pass that along as I found it interesting. The guy I talked to actually used to MAKE them, and was really cool to talk to and very helpful.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

That is interesting!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I agree with creating a wrap. Create a coordinate system rotated on the Z and a curve from equation to wrap around the cylinder. Then sweep the curve.

There is always more to learn in Creo.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Interesting, I've never seen an endmill like that. I can see the advantages for it though in breaking up chips. Is it used for things like stainless that are a PITA to machine and/or for high material removal rates?

As far as actually modeling it, do you want something that just LOOKS kinda like it, or do you need to actually model the geometry? If it needs to be accurate, you're going to have to measure it and that will probably determine your methods. From what I see, a simple wrap isn't going to be enough.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

My guess would be that it cuts smoother because of chip break but maybe also because it will maintain more points of contact as it spins, so might be less apt to chatter? Maybe the type of contact it makes prevents harmonic vibration?

I can't imagine what a nightmare it would be to sharpen one of these. It must be done by very special equipment.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

'Sup Ken!

Yeah, I've seen a bunch of "roughing" milling cutters over the years, some with "teeth" instead (to break up long stringy chips that break tools and FUBAR the material being machined), so, maybe this is simply a variation on that. This example below seems to have MUCH simpler geometry (to model and especially to manufacture/grind the edges). So, to me, this looks like it's made to be used on stainless or other "gummy" metals and/or for fast material removal.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I also have never seen end mills like these until working here. They are very old, and I am not sure if they even make them anymore. I am not sure if we use them for their intended use or not, but we use them here for finishers, and they run at pretty low rpms, usually 150 or so. The geometry of these is pretty impressive, even more so when you find out that they are older tools. The old man here says they use to sharpen them here, and that they weren't actually bad to sharpen. He also said not to climb mill with them, because he says they explode when you do.

As far as modeling it goes, I did not need it to be accurate and got it close enough to work. I posted a screenshot above in the accepted answer.

Thanks everyone!