Community Tip - If community subscription notifications are filling up your inbox you can set up a daily digest and get all your notifications in a single email. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: How to apply thickness to imported surface mod...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

How to apply thickness to imported surface model (stl,obj or any format) and make it solid for 3D printing in creo 3.0 Parametric? Help!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

How to apply thickness to imported surface model (stl,obj or any format) and make it solid for 3D printing in creo 3.0 Parametric? Help!

I use educational version creo 3.0 parametric.

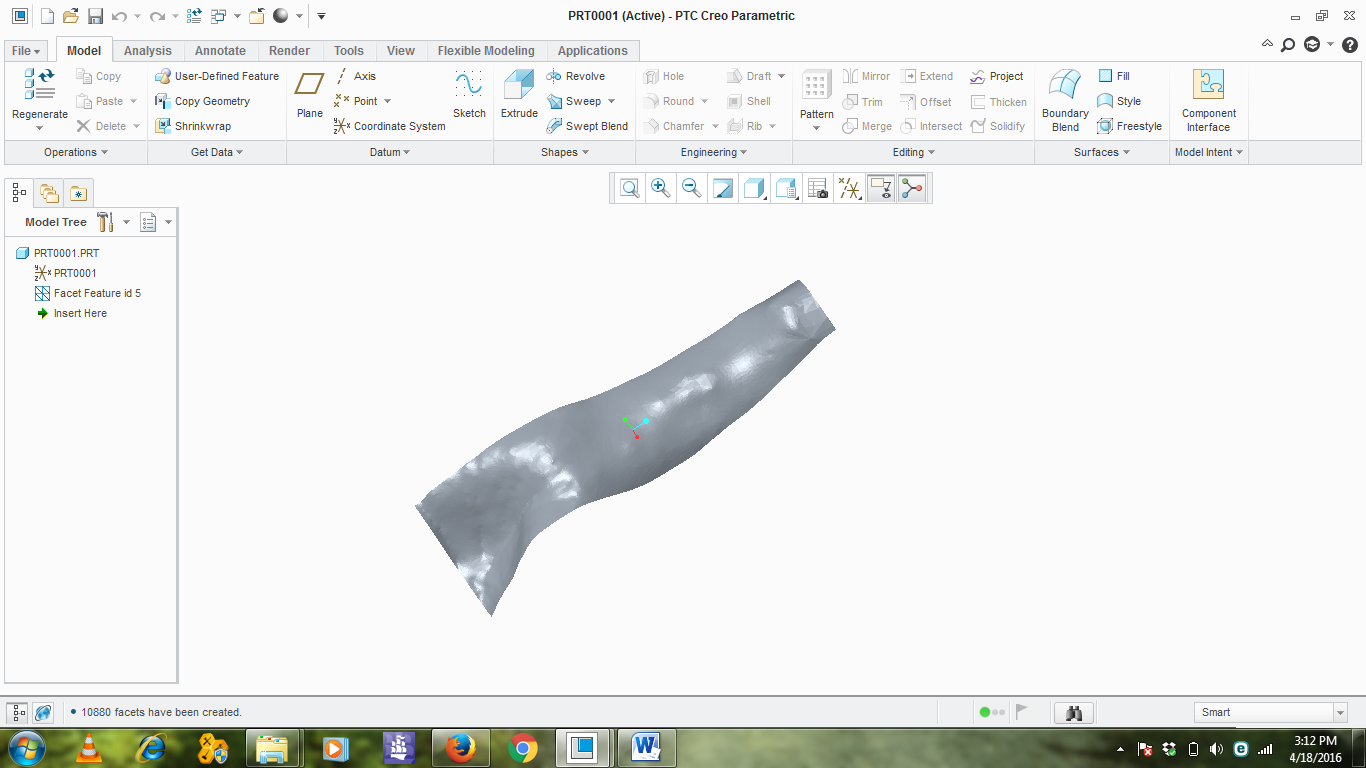

I have an orthotics project going on that we want to try 3d printed model on broken wrist. I used 123D catch to 3D scan my hand, I downloaded stl, obj file of my hand from 123D catch. I removed undesired materials of the model in Meshmixer and exported to creo 3.0

Now, I want to increase the thickness of the surface model exported from meshmixer and meshlab.

I couldn't make any editing in the software (no thickness applied). I want to make the model solid by applying 5mm thickness.

But, my friend could apply thickness to this surface model in solidworks. What he did was:

import into solidworks > copy surface (move by 5mm in desired direction) > select outer loop of first surface > extrude perimeter 5mm (up to other surface) > knit surfaces and form solid > export as stl file (Now, its useful for printing)

I have attached the 3d scan file edited in meshmixer, surface model of scanned hand(ready to export in creo)

I would be very thankful if any one could help me with suggestions!

Cheers,

Thanks!

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

Solved! Go to Solution.

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

the "extrude up to a surface" would work with your model.

To make a surf ontop of your surf ain´t that hard if you know Isdx, but could also be done using curve thru points and Boundary blends. Just use your import as a base for modelling, and attach your curves to it when making the new surf.

//Tobias

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

First i would suggest that you use a step for importing in creo. If the program you are using cant export step, then just google for a converter that will translate your wrl to stp. Then in creo, if you are lucky... you can use "thicken" and your done!. (or offset and use the option "create side surf" and then "solidify".

Otherwise , if you just want a "printable" (is that a word?) model, then you either create a extrude from a datumplane that use the option "up to surface" for determing the depth of the extrude (i.o.w extrude up to your imported surf and you got yourself a solid. then create some cuts to remove unwanted material. This will give you a rough model , whit the "right surface" on one side... (is that enough? or do you need both sides of your import?)

If thicken cant be used, then what i would prefer to do is to make a surf , using isdx or maybe freestyle , on top of the original surf and just make it as close as possible and then use this surf for thicken. Or create the surf and offset it . Then connect the imported surf, and your offset surf using boundaryblend, merge and make it solid. (then, again "one side" is your scan file, but maybe thats close enough?)

Maybe there are other ways to do it ?

//Tobias

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thankyou Tobias!!!

I am trying it. Here is my stp file. Can you please try it out for me!!! Coz its for medical purpose, its one surface needs to be smooth. This is to 3d print and test in my hand. If successful, we'll try in real life situation (disaster response). For now, its kind of a R&D.

I have attached my stp file

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

the "extrude up to a surface" would work with your model.

To make a surf ontop of your surf ain´t that hard if you know Isdx, but could also be done using curve thru points and Boundary blends. Just use your import as a base for modelling, and attach your curves to it when making the new surf.

//Tobias

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

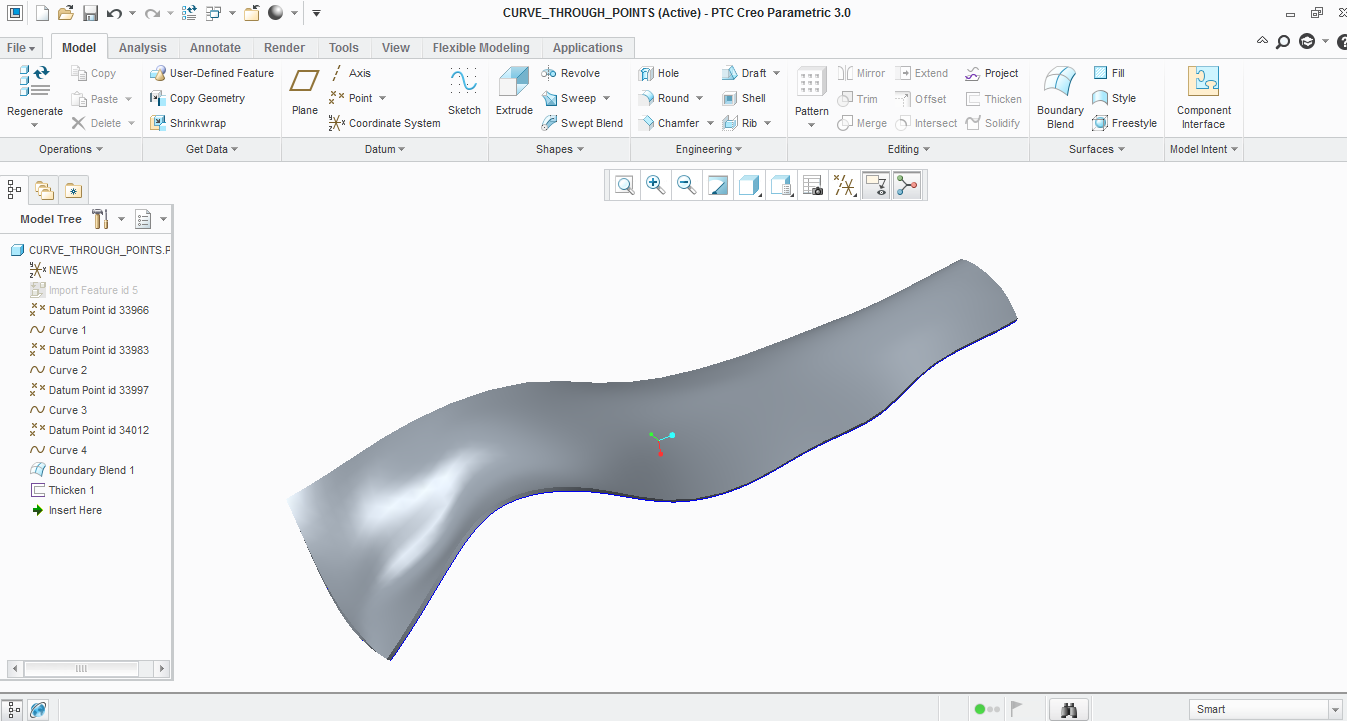

Curve through points worked ![]()

Thanks a lot friend!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

glad to hear that, please upload a pic of you final model!

/Tobias

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Edited file Original scan file

I did following:

1. imported stl file

2. draw curves through points around hand covering different surfaces

3. Boundary blend those curves

4. hide original stl file(delete!)

5. thicken surface to 5mm

Now, the design is ready.

Problem with this process is:

We want the actual surface of hand or any body part covering intricate details like crease of palm. We obtained a smooth design.

If there is any process that we could directly thicken or solidify the scan surface file, it would be good for us!

I couldn't thicken step file, neither offset it to create solid.

"Or create the surf and offset it . Then connect the imported surf, and your offset surf using boundaryblend, merge and make it solid. " Can you teach me in detail this??

Thanks!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

sweet! What you can do is to add more curves thru your geometry to get a more "exact shape" . (add curves where the geometry deviates too much) .

Well what you probably "can do" is like this. From a datum plane, create a extrude (in "depth") goes "to selected" and select you imported surf. Now you should have a solid "body" that got your import surf on one side. Then just hide your import. And "voila" your import surf is now solid but you got way to much material... So:

Then, create a surf like you did in your example, offset it 5mm , and use it to cut away unwanted material using solidify. (...and your done!)

If you want to offset your import, i guess the easiest way to do it is to get REX (reverse engineering extension) and import your geometry there to get a smooth surf from the beginning to work with. (unless your exporting program cant export anything else than stl) The main issue is that your import is made out of a lot of triangles(Stl) and thats more or less impossible to offset...

//Tobias

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Please teach me how to edit STEP file in Creo 3.0 Parametric

here is details of my problem friend!