Community Tip - You can subscribe to a forum, label or individual post and receive email notifications when someone posts a new topic or reply. Learn more! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: How to make imported part show solid lines in ...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

How to make imported part show solid lines in a drawing section

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

How to make imported part show solid lines in a drawing section

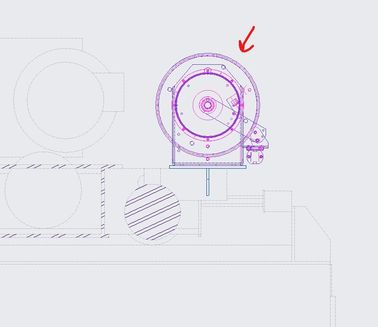

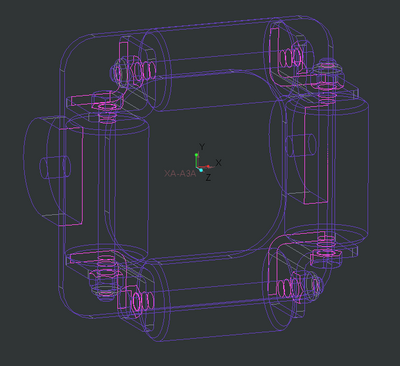

I am using Creo Parametric 7.0 and am making a drawing and one of the parts in the assembly has been imported from a .step file. When I take a section of the assembly, the imported part instead of showing just solid lines, shows all of the quilt lines in magenta and purple. So essentially, you are seeing through the part, no longer just the nearest surfaces to the section plane. I have found some threads about using the import data doctor and have tried to make it a solid part, but have had no luck.

Is there a way to fix this in the drawing itself, or does it need to be done in the part?

The first picture is what it looks like when I take a section, the second picture is what it looks like when I dont take a section (what it should look like).

Solved! Go to Solution.

- Labels:

-

2D Drawing

-

Assembly Design

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You are correct that your import geometry has non manifold quilts which is why it is not being solidified. The geometry is trivial (cylinders and prismatic rectangles) and the errors are almost certainly caused by the method used to export it.

It can be fixed with IDD but you should try exporting the assembly source file as an assembly in STEP format. Import it as an assembly in Creo. That may resolve the issue.

Every magenta edge you see in this image is open.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It's likely that your imported STEP file is not an actual manifold solid in Creo. If there is bad geometry in the file, things like intersecting surfaces, etc. then a solid is not created and the result is just a bunch of surfaces. Thus your troubles with making a section cut.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

How would you go about fixing this? The step files are coming from a vendor. Is there options to change when importing it that will create a solid part?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

There are some settings that can be used to improve translation but you would need to know the export filters in the originating CAD system to employ them effectively. One item to check is accuracy in Creo, it should match the resolution of the STEP export. Absolute accuracy in Creo has units of length and you will need to manually set that up in Creo on your end.

Confirm with the source that they are exporting a solid STEP model and that when they bring this STEP back into their CAD tool it is indeed solid.

The STEP standard used can also have influence on success.

Import data doctor tools are useful but using them can be incredibly tedious and time consuming and requires some knowledge of how manifold surfaces "work".

Before you do any of this I would try opening the STEP model in Solid Works or another CAD program. If it opens as a solid model in the other CAD program then you can export that and bring it in to Creo. SW often will import as a solid when Creo does not. Creo can open SW files so you would not necessarily need to export it in a neutral format.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This is a cross section "thing" when a model has surfaces (quilts).

In the model, edit definition of the cross section, go to the models tab and check the box for Include Quilts

Also, vote for the improvement to add a config.pro option so a user can set it so this box would be checked by default

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The problem with this is that I need the part to show in the section view. If i check that box the entire part disappears. I need it to show up, but as a solid body.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The part should not disappear completely but should x-section with the correct hidden lines. Of course with a surface model, there will be no section lines since there is no solid geometry.

You may also have to go to the view properties, View display and check YES for hidden line removal for quilts.

Your best option is to get the model as a solid but you may be able to work-around the issue if you can't do that.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Also, sharing the model and drawing (simplified) if possible would help us get you to the quickest solution.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

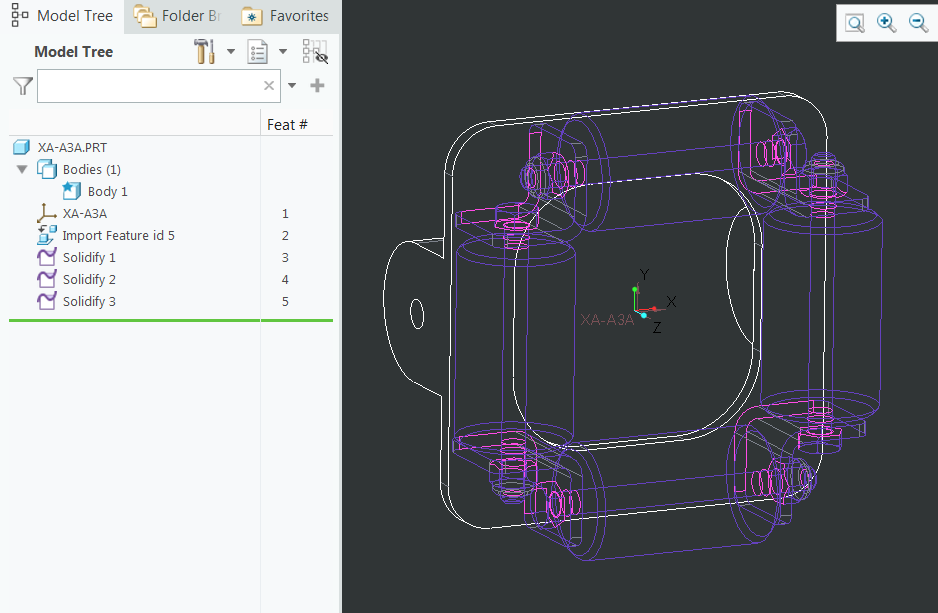

I think I have narrowed it down to the .step & .iges files that we are using to create parts are having issues with the quilts and having open surfaces and will not coming in as solid parts. I was able to get some of the parts to solidify, but some have open features and are not working. I have tried to repair them with no luck. Attached is a file of an example. Is anyone able to make the entire part solid? I can make certain parts of it solid, but am not having luck making the entire part solid. I have tried a few things in the IDD but am not too familiar with it and didn't have any luck.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You are correct that your import geometry has non manifold quilts which is why it is not being solidified. The geometry is trivial (cylinders and prismatic rectangles) and the errors are almost certainly caused by the method used to export it.

It can be fixed with IDD but you should try exporting the assembly source file as an assembly in STEP format. Import it as an assembly in Creo. That may resolve the issue.

Every magenta edge you see in this image is open.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Unfortunately a lot of the times we are just sent files from customers/vendors and do not have control over what export features are used. Is there an easy way to do it in the IDD?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

There is not really anything easy about IDD fixes. The heal function is sometimes easy if it works but on this model it is not an option with the default import filter settings. IDD is manual other than the heal function and it gets quite tedious.

If you are importing data on a regular basis then you should have your company establish standards and requirements for what is used for imported geometry so you can minimize this issue. Data format and settings used for export so that it works when opening in Creo.

I was able to solidify some geometry in part mode as shown in the image below. In theory you can do this for all of the elements once you close up the quilts. You don't have to use IDD to do that you can just create the missing surfaces and merge the quilts as required.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Another trouble I see is that this STEP file seems to have been created as a part, but should have been an assembly? Doing this kind of thing pretty much guarantees troubles when surfaces overlap (nut face on wall surface, for example), concentric items that almost, but don't quite touch each other (dowel in hole), etc.

What I've done, because it's all I can do, is to create a model of my own, using the STEP data as a reference. Not usually any fun, but when I have to have a solid part to show in the section cuts, they're forcing me to do it.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I did identify the assembly exported as a part issue above. I agree with you that if it were exported correctly it would likely import into Creo as a solid assembly.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Oh, okay. Sorry.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

As mentioned, you have imported a surface model that is not "closed" into a solid. You can fix it manually, which can be EXTREMELY tedious and pretty much impossible if you're not fluent in surfacing, or, you can try my personal cheat: If you have Solidworks, import the file into Solidworks, run the diagnostic and fix it there and if SW fixes it as a solid, then make a new STEP file and import it into Creo. Since I have both (but only use SW for fixing these files), I've been able to save a TON of time over the years doing this. SW has a MUCH better "fixer" than Creo, sadly... If you can, I'd try that first.

Best of luck!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yep, I'm doing the same thing. Even Creo models that contain geometry checks and export poorly can be brought into Solidworks, automatically fixed, and re-exported.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I tell ya, that's the easiest way I've found. It's amazing the garbage SW will fix. It's not good for anything else, but it's good for that! LOL Creo needs to step up their game on this area....among many others.