Community Tip - Did you know you can set a signature that will be added to all your posts? Set it here! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Hyperelastic material with contact – looking f...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Hyperelastic material with contact – looking for the best approach

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hyperelastic material with contact – looking for the best approach

Dear Creo simulate users.

I would like to simulate one structure touching another structure. Once the contact happens the rubber part is deformed at the same time that the shaft bends.

I would be interested not only in the stiffness of the structure but also the stress in the parts.

The main problem is that even using ½ of the model (and using mirror constrains) this type of simulation still would take several hours even with not much elemnts (ex.10000) – Maybe Simuklate simply does not use all CPUs in this case, I don´t know.

Thus a much more interesting approach is to run a 2D simulation. It is order of magnitude faster. Unfortunately I do not have too much experience in 2D. I tried it with another cases/assemblies and the result seems consistent. However I don´t see the right way to setup this model in 2D.

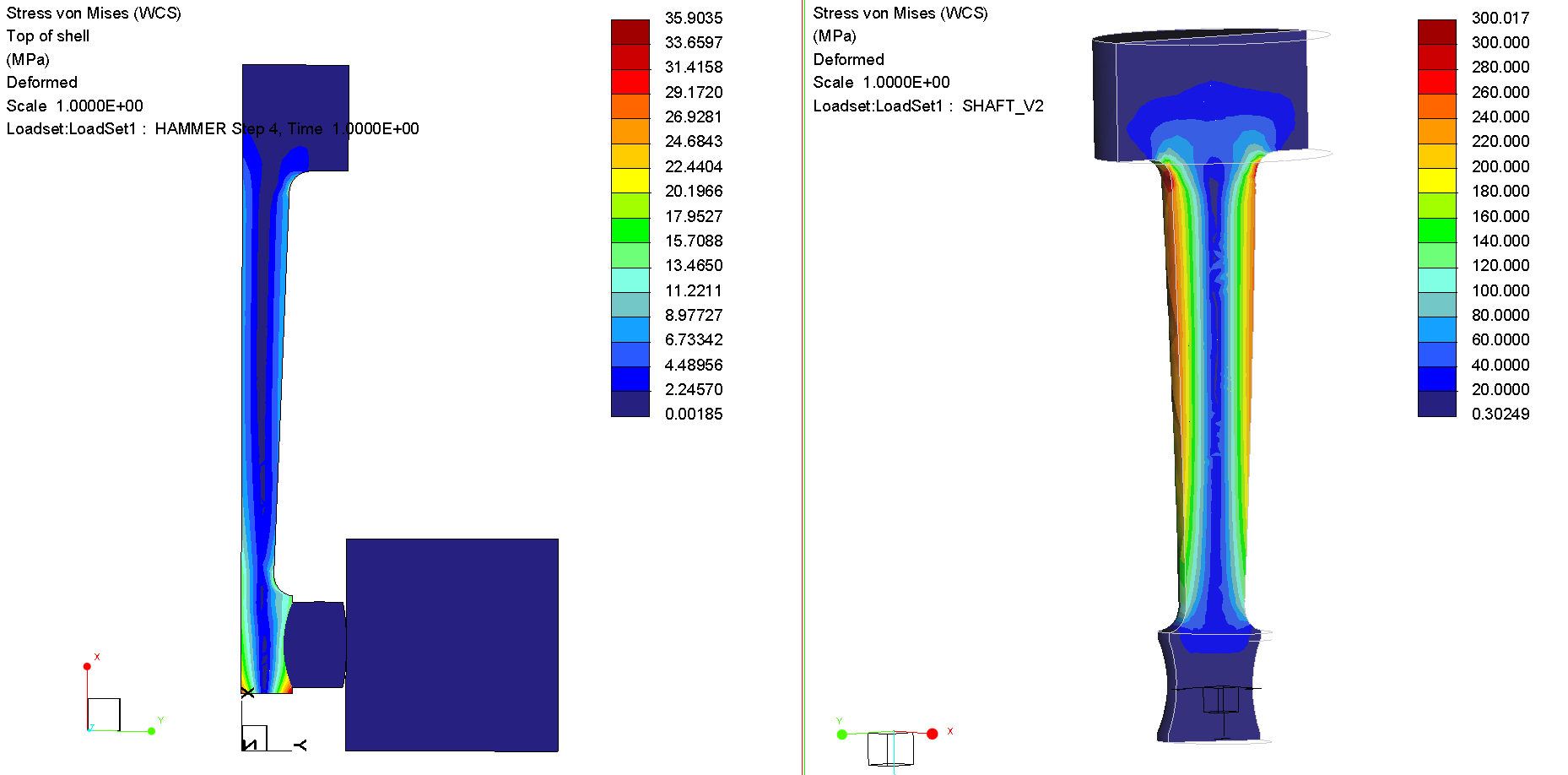

For example I tried 2D axisymmetric model (using ¼ of the model) but the result seems simply wrong. For example the shaft shows an odd distribution of stress and the bending of the shaft (displacement) does not match what I would get with the full 3D model (shaft only) using the same input force.

I would be glad if someone could give me good hint in how to have quick and reliable results for this case.

I´ll post the CAD model latter

Thank you in advance

R. Rabe

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Labels:

-

Assembly Design

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

If you say the shaft bends, that would mean there is movement of one of the parts in the XY-plane in your 3D-model?

In that case you cannot use the rotation symmetric 2D-model, because that is limited to all loads and displacements being symmetric around the axis of symmetry.

So your best bet is the mirror-symmetric model you made. You can probably still speed that up substantially. For instance by using forced displacements instead of forces. You can remove friction from the contact (just make sure it does not influence the results too much). Your rubber properties might also cause for some numeric misery; try to decrease the Poisson's ratio slightly to see how that influences the calculation time (and again: check if the influence on the results is negligible).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks Patrick

I think your explanation made me understand why I was having some good results in one 2D axisymmetric problem but bad results in this one.

I had another model (with good results) that the rubber was being pressed against a plane (picture below) and in this case the load/displacement is indeed symmetric around the axis of symmetry. As you have pointed out this will not be the case in my current model with lateral load.

I did some tests and I found that in some cases the rubber property (when mixed with contact interface) was the main source of long computing time or simulation fail due to lack of convergence. In some cases a small changes in the rubber property solved the problem but it also changed its mechanical behavior enought that the results did not fit anymore the reference part.

By the way the rubber properties I got from colleagues using another FEM and real tested parts – so what I was trying to do was to “replicate” the model in Creo 2.0 to learn more about this capability. So far other FEM seems to be handing well this type of problem – but I have no idea how long takes a simulation. Besides their focus is to get the best result for a given part and not to design the part. This means that they may have solutions that will fit very well to a particular geometry but that does not need to be so robust that can work in any geometry.

Using infinite friction or frictionless contact were also factors that could made a simulation to finish or not (see that I´m not discussing if the result was ok or not – simply that the simulation finished). Sometimes instead of a material change refining the mesh helped. Even so even a small geometry change in the contact interface was enough to stop the simulation in the middle. And If I want to do run optimization I´ll probably have this issue again.

I had same model using enforced displacement but I did not noticed any substantial improvement. Maybe the solution is ready after 5h instead of 6h but in this case I was hoping to find something a lot quicker – that was my motivation to switch to 2D.

I tried to work with a slice of the 3D model and cyclic constrains – but again it may be valid only if the load/displacement are symmetric around the axis of symmetry (and thus I´ll be doing the wrong thing again – but now in 3D).

To see how “desperate” I´m looking for a way to speed up the simulation time I even played bit with the “mse_contact_tolerance_factor” in the config file. Sometimes I had a substantial reduction in simulation time and nearly the same result but in other models the result was simply rubbish. So it is a complex tool a dangerous way to go if you cannot “benchmark” the result or have sure that the result is reliable or not (analyzing convergence status for example?).

The search continues and thus any hint is welcome.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

A couple of thoughts:

- Are you using a mapped mesh? It increases the manual effort in setting up the model, but may improve run-time.

- Just to check your hardware influences, could you post the "Memory and Disk Usage" from the end of an .rpt file?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yes, I used mapped mesh in other tests (before moving to 2D) and I have not noticed any mapped configuration that could really speed up the simulation.

In this current model the mapped mesh is not working well (curved surfaces…). I´m thus running a slightly finer mesh in the possible contact surfaces.

Specifically for the above assembly I have modified it and now I´m running 3D simulation. One simulation with force input and another with displacement input.

After several hours the force input simulation were still in the 2nd of the 4 steps. The number of elements in the mesh is ~20000

I´ll let running overnight and hopefully this week I have a result – so I can check the .rpt file.

But regarding the hardware, it is a Dell T3610 with Hybrid HD and 16GB Ram. I don´t think it is bad at all and anyway it is all that I can use.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Ok

Finally one simulation finished - the one with displacement input.

Some information that may help

It is a 1/2 model with mirror symmetry (similar to my 1st picture in this thread)

I let some of the CPUs free for other things in case the computer was scheduled to do something else overnight (does it make much difference?)

It was an overnight simulation (no other parallel use)

I set the msengine.exe process as "high" in windows

Processor Intel(R) Xeon(R) CPU E5-1650 v2 @ 3.50GHz, 3501 Mhz, 6 Core(s), 12 Logical Processor(s)

Creo 2.0 M150

-----------------------------------------------

Run Settings

Memory allocation for block solver: 3072.0

Parallel Processing Status

Parallel task limit for current run: 12

Parallel task limit for current platform: 64

Number of processors detected automatically: 12

Engine Command with the specified command line options:

mech\x86e_win64\bin\msengine.exe b_Contact_Disp_input -i . -w . -solram 3072 -sturm default -results_always -num_threads ALL_BUT_2

Model Type: Three Dimensional

Points: 3031

Edges: 17884

Faces: 28246

Solids: 13393

Elements: 13393

Contacts: 1

Memory and Disk Usage:

Machine Type: Windows 7 64 Service Pack 1

RAM Allocation for Solver (megabytes): 3072.0

Total Elapsed Time (seconds): 49266.76

Total CPU Time (seconds): 60761.50

Maximum Memory Usage (kilobytes): 7821857

Working Directory Disk Usage (kilobytes): 401552

Results Directory Size (kilobytes):

326305 .\b_Contact_Disp_input

----------------------------------------------

My 1st impression is that the there is no significant bottleneck (although CPU time / Elapsed time could be better - have to check that).

So I´m afraid that there is not much to do to speed-up this type of simulation. Contact is a slow simulation - and this one took almost 17h.

Thus I think I have all the answers now. As final verification an overnight simulation is acceptable. If the goal is optimization it is needed something a lot faster - and as it was explained unfortunately 2D axisymmetric is the wrong simulation for this model.