- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Interferance Report Error

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Interferance Report Error

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Interferance Report Error

Creo 2 Parametric, M160

When I do an global interference on my assy, two parts report a very high interference, about 7.5 cubic inches. There is no clear interferance between the parts. This value is consistent between a global interference or pairs clearance checks ,whether at the top level or at the sub assy level. I created a cut out of one part into the other, which should eliminate all interferences and it still reports the same value. In fact, it turns out the volume reported is exactly equal to the volume of the two parts together. For some reason Creo thinks they fully overlap when they clearly do not.

Has anyone seen this before and have a work around? My concern is trusting the analysis in other areas, or missing and actual interference between these two parts because I assume this is just a glitch.

Solved! Go to Solution.

- Labels:

-

General

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Doug Schaefer, I just retested this issue in CP3 M080 and it appears to now be resolved. Tech support has never updated my case, so I just emailed them to find out what build it was corrected in. I'll let you know...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This may sound silly, but are you in an exploded view or a drawing snapshot? IE maybe the parts really are overlapped?

Have you tried putting them in a brand new assembly with a distance of 100 units apart?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

No, in fact I've since seen it in another sub-assy in the same database. This time it was with screws where I'd expect a small interference, but it showed the entirety of both parts as overlapping.

Unfortunately, we are not current on maintenance so I cannot send it to tech support to evaluate.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Are you able to share the models? I can test it in the latest version of Creo, and I do have maintenance if necessary. ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

They are client models,i'd have to get permission to share them. I do have Creo 3 loaded, I can give them a try there to see if I get the same results.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

OK, it seems that today, after shutting a restart of both Creo & my laptop, I cannot reproduce the issue in the the initial assy, but it remains in the other. No changes have been made in any of the components involved.

Here's a detail screenshot of the two parts, a screw (McMaster download) and a plastic panel:

Interestingly, the reported interference between multiple instances of the same screw is not identical, but very close. The volume of the panel is 0.629878, the volume of the screw is 0.001687. Combined volume is 0.631565. In the first occurrence the reported interference was exactly the combined volume of the two parts (both molded parts in that case), in this case it is not.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Just out of curiosity, did you download a Creo model from McMaster or a neutral file (STEP or IGES)?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

STEP file. it is solid with no geom checks. It was created in WF4.

Keep in mind, the first occurrence was with two native Creo files.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Creo 3, M040 reports the same results:

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

How can the interference be larger than the combined volume of the parts??? Even with no holes in the plastic part, the total interference should not exceed the volume of one screw. Does the amount of interference change if you suppress the screw holes in the panel?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I'll look into it later, I've got to get some files out. ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hate it when work gets in the way of a good mystery. ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yep.

I did ask a colleague and the client to look at it and they all got the same result.

Tomorrow is a bit lighter, I can play with it a bit.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The ID & OD of the boss were made with the same feature, but I made the ID construction geometry in the sketch and suppressed the related draft & round. I then got a result that makes sense:

Restoring the hole, draft and round returned the same, odd results. I also tried suppressing the draft and round, leaving the ID. That also produced reasonable results:

With just the draft and not the round, I got odd results again.

The draft makes the Id of the hole interfere with the minor dia. of the screw near the tip, but is clear of the minor dia at the head. That shouldn't give the results I'm seeing, but I wonder if that's contributing to it?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I am unable to reproduce the issue in Creo 3. I'm wondering if the problem is specific to that model. If you create a new test model with a similar boss and the assemble the same screw to it, do you still see the same problem?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yes, with a simple panel with a boss of identical dimensions, a simple PCB and the same screw I get similar results. I've attached that assy in a zip file (Creo 2, M160).

If you change the ID draft (Draft 1) to zero, the odd results go away.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yep, I'm seeing the same issue in Creo 3. Let me open a case with tech support.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Changing the draft angle to 2 degrees (more interference) also generates accurate interference values.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I only tried 0.5 degree and 1.0 degree, but found the same results. Only zero draft produced accurate results.

Thanks for opening a case, hopefully there's a simple fix. Thankfully, at least in the situations I've seen, the error is large enough to be very obvious.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Doug Schaefer, I just retested this issue in CP3 M080 and it appears to now be resolved. Tech support has never updated my case, so I just emailed them to find out what build it was corrected in. I'll let you know...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Tom,

I had forgotten about this, thanks for following up. I tried the original assy and CP3 M070 and it seems fixed there as well. I don't have a build of CP2 newer than M160 installed to try it there.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

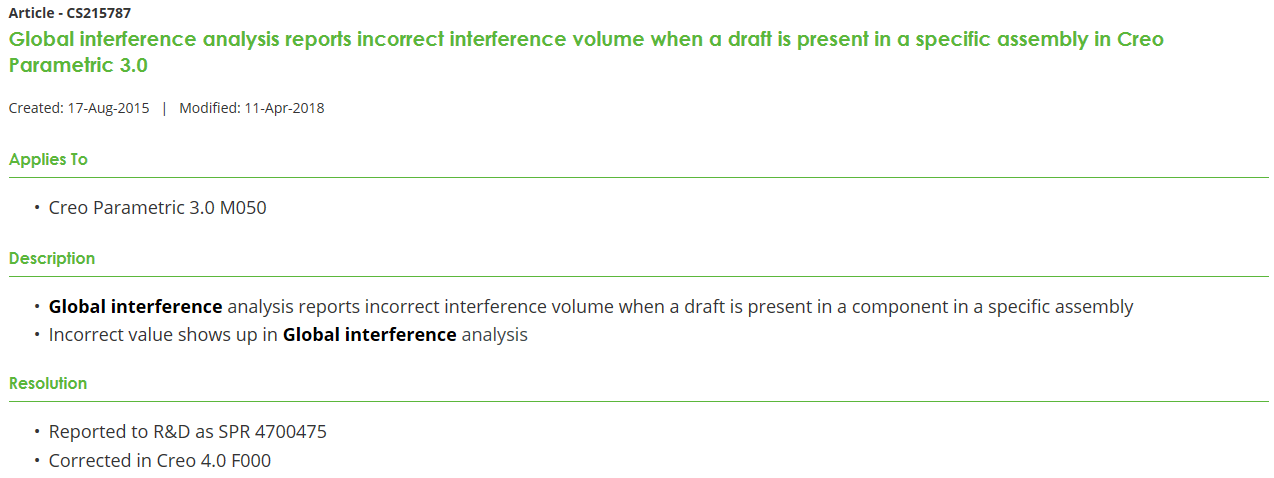

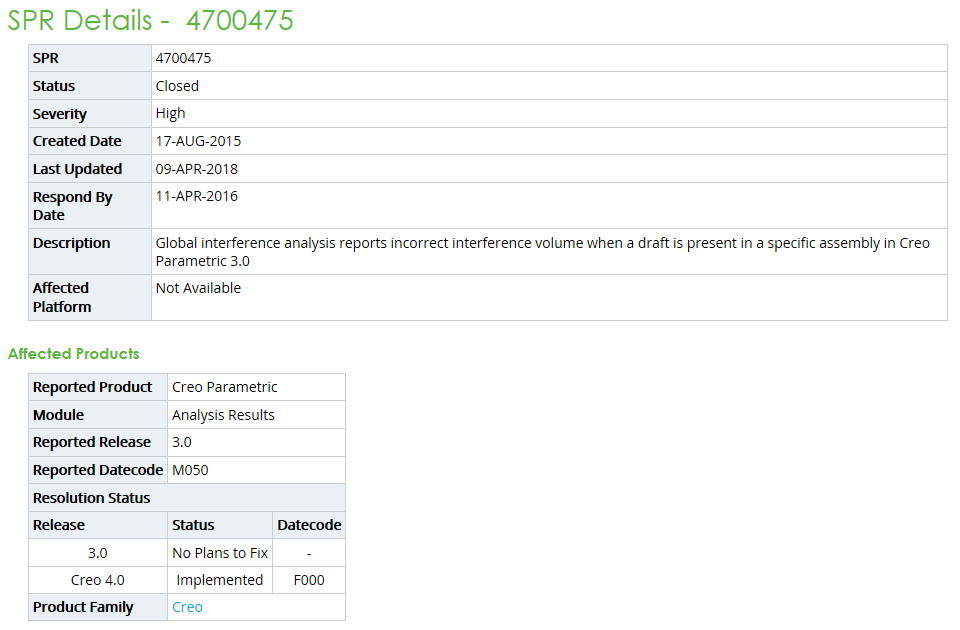

I finally received a response from PTC... after 2 years. This has been corrected in Creo Parametric 3.0 M140 and 4.0 F000.

https://www.ptc.com/en/support/article?n=CS215787

https://support.ptc.com/appserver/cs/view/spr.jsp?n=4700475