Community Tip - You can subscribe to a forum, label or individual post and receive email notifications when someone posts a new topic or reply. Learn more! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Is it possible to change the tolerance standar...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Is it possible to change the tolerance standard without Creo changing explicitly set tolerances?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Is it possible to change the tolerance standard without Creo changing explicitly set tolerances?

We have dozens of older parts/drawings that were made before we found our footing with Creo... Now, whenever we open an older part/drawing and try to bring it up to snuff (adding shaft tolerances, using the block tolerance for what doesn't need to be explicit, etc.) someone has to make a note of all the existing tolerances because changing from ANSI to ISO changes all the explicitly set tolerances to the "standard".

I understand this might be useful to some people, some of the time - but am I really to understand that this "best of the best" software package isn't smart enough - or can't be configured - to leave what is explicitly set, well enough alone?

- Labels:

-

General

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Please give some screen shots for a better understanding.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

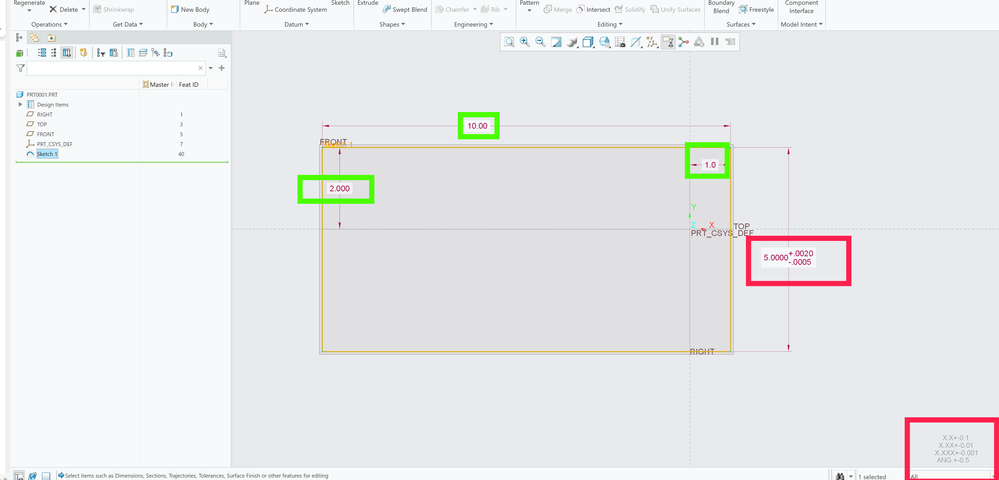

A new inlbs_part_solid_abs part with a rectangle sketch. Tolerances in green boxes are assumed by the number of decimal places. The red box has an explicitly set tolerance.

Upon changing the standard to ISO in model properties, the red tolerance gets overridden, whereas the ones interpreted by the number of decimal places keep their same number of decimal places.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

That does not look like Creo Elements Direct Modeling.

SolidDesigner-20.5 + PE8 + PhoenixPDM + Solidworks + Blender

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You should move your question to "Creo Parametric" to have a better chance to get an answer.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Status has not changed.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

We are having the same problem with Creo Parametric 8.0.4.0. Is there any solution for this? Is this stupid and dangerous behaviour fixed in some newer version of Creo?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

+1 on this issue.

This is the most annoying bug I come across regularly. Has anyone found a solution?