Community Tip - Did you know you can set a signature that will be added to all your posts? Set it here! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Measurement is incorrectly not showing shortest di...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Measurement is incorrectly not showing shortest distance between edge and surface.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Measurement is incorrectly not showing shortest distance between edge and surface.

I am using Creo Parametric 7.0.4.0

Hello,

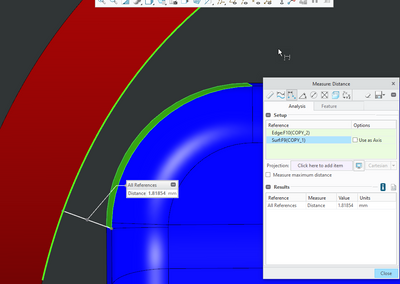

The measure tool is not giving the shortest distance between and edge and surface. Has anyone figured out why this happens?

It seems to use the edge of the surface instead of the surface geometry.

Solved! Go to Solution.

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Solution:

https://www.ptc.com/support/article/CS364438?source=Case%20Viewer

Description

- Measuring tool is not giving the shortest distance between the edge and surface

- Measuring tool provides incorrect results when using calculating distance from edge to surface

- Information about Setting Advanced Clearance Checking

Cause

- You can control the calculation accuracy used for clearance checks.

- The system's default method of clearance checking is to check for a local minimum at random points. You can specify a slower but more accurate method of checking for clearance and distance measures, whereby the system computes the high quality first guess based on refined triangulation.

Resolution

- Set config option clearance_triangulation to low

- clearance_triangulation configuration file option settings:

- none—checks for a local minimum at random points (the default)

- low—corresponds to a 7 x 7 minimum grid on a surface

- medium—corresponds to a 14 x 14 minimum grid on a surface

- high—corresponds to a 21 x 21 minimum grid on a surface

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The edge of a surface is part of the surface so if that edge is closest then the measure is working as designed. Even though you are selecting a surface its domain is defined by boundaries. These boundaries would be congruent with edges. It is hard to tell from your pics what the minimum distance would be.

If you have a license for BMX module you can verify the result.

If you think it is not working correctly then you can place a field point on the surface and create a measure distance analysis feature to be used in an optimization study. Set the objective to minimize the distance and run the study to compare to the measure tool result.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hey tbraxton. Thanks for responding.

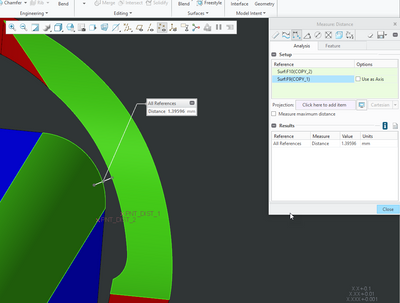

There a locations on the blue surface that are closer than the edge.

If I measure surface to surface, the closest point of the red surface is the same edge in example #1. But the blue surface location is shown mid surface.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I now understand, you see different results when you expect them to match. Nothing comes to mind to explain that. I would need to query a model with those surfaces to investigate. If you post something I will see if I can replicate the results you are seeing.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I'm asking PTC TS to file an SPR on this issue

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Solution:

https://www.ptc.com/support/article/CS364438?source=Case%20Viewer

Description

- Measuring tool is not giving the shortest distance between the edge and surface

- Measuring tool provides incorrect results when using calculating distance from edge to surface

- Information about Setting Advanced Clearance Checking

Cause

- You can control the calculation accuracy used for clearance checks.

- The system's default method of clearance checking is to check for a local minimum at random points. You can specify a slower but more accurate method of checking for clearance and distance measures, whereby the system computes the high quality first guess based on refined triangulation.

Resolution

- Set config option clearance_triangulation to low

- clearance_triangulation configuration file option settings:

- none—checks for a local minimum at random points (the default)

- low—corresponds to a 7 x 7 minimum grid on a surface

- medium—corresponds to a 14 x 14 minimum grid on a surface

- high—corresponds to a 21 x 21 minimum grid on a surface