Community Tip - Visit the PTCooler (the community lounge) to get to know your fellow community members and check out some of Dale's Friday Humor posts! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Multiple rows in BOM of the same part

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Multiple rows in BOM of the same part

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Multiple rows in BOM of the same part

Hello,

in my BOM I can see that a specific part appears twice, so it has to entries in the BOM.

I used it in total 24 times in my assembly.

One entry has 16 parts (qty), the other one 8.

It is for sure excatly the same part (.prt), still I am not able to combine it.

I saw the following article: https://community.ptc.com/t5/3D-Part-Assembly-Design/BOM-not-merging-part-quantities/td-p/571318

I did excatly the same, still the problem occurs.

Let me know if you need some files, but the file is quite a big assembly with many many parts.

Greetings

Spedex

Solved! Go to Solution.

- Labels:

-

2D Drawing

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Fixed it in the end by deleting them and building them in again.

Thank you everyone for helping.

Greetings

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Is it flexible components or assembly cuts or?

What is in your BOM table other than index, qty? Do you list weight or ??

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Not sure what flexible parts are, but I do not think that I am using something like that. Just normal parts in an assembly and I am viewing the drawing of the assembly. In this drawing there is the BOM.

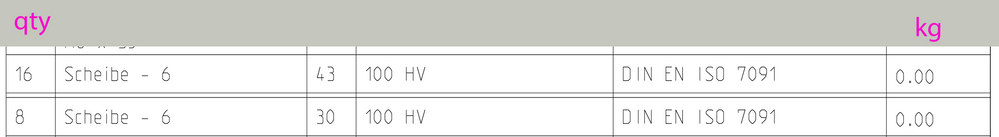

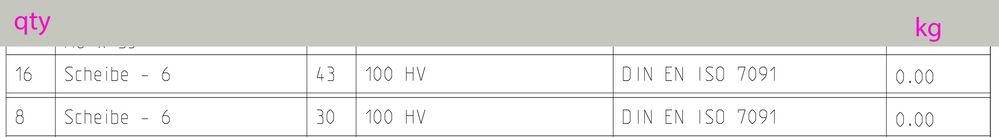

Here is a picture of the entries:

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Flexible components are things that can change shape in different assemblies. Mostly used for hoses or wires.

Your disks are probably not flexible.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Ok definitely no flexible part then.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Can you show a segment of your BOM table?

Are you using any repeat region relations?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Here is a picture of the two entries:

I do use relations as far as I know. Sorry that I am not sure because I am using a preset template. But I know for sure that I don't have to fill out for example the weight manually. It automatically reads out the weight of the part and fills it inside of the table.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

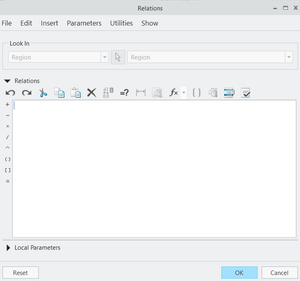

To see if there are any repeat region relations, do this:

Click on the Table tab with the drawing sheet that has your BOM on it

Select Repeat region from the task bar

When the Menu Manager opens, select Relations and then click in your BOM table

This will open the Relation editor and show any existing relations for that repeat region.

Post your relations, if there are any.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

No relations as it seems then.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi,

It may depend on some component parameters defined in the assembly and recalled in a column of the table..

To easily study the problem, i would suggest to try to simplify the table by deleting the columns in sequence with the exception of the model name and see if the quantities are combined.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi,

usually this problem is caused by different weight of these components in case that they are intersected by assembly feature.

Note: AFAIK you are using Student version ... therefore it does not make any sense to upload Creo files. Instead of it attach pictures.

Martin Hanák

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

But how should they have a different weight? It is the same part. The mass is 0.000988 kg, so round about 1 gramm.

Or are you talking about the total weight (so pieces x mass per piece)?

Here is a picture of the two rows. Note that the BOM lists the weight in kg, so this leads to a weight of round about 0 kg.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

@Spedex wrote:

But how should they have a different weight? It is the same part. The mass is 0.000988 kg, so round about 1 gramm.

Or are you talking about the total weight (so pieces x mass per piece)?

Here is a picture of the two rows. Note that the BOM lists the weight in kg, so this leads to a weight of round about 0 kg.

Hi,

please attach picture of whole table.

Also please publish what parameter is included in weight cell (eg. weight[.2]).

Martin Hanák

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

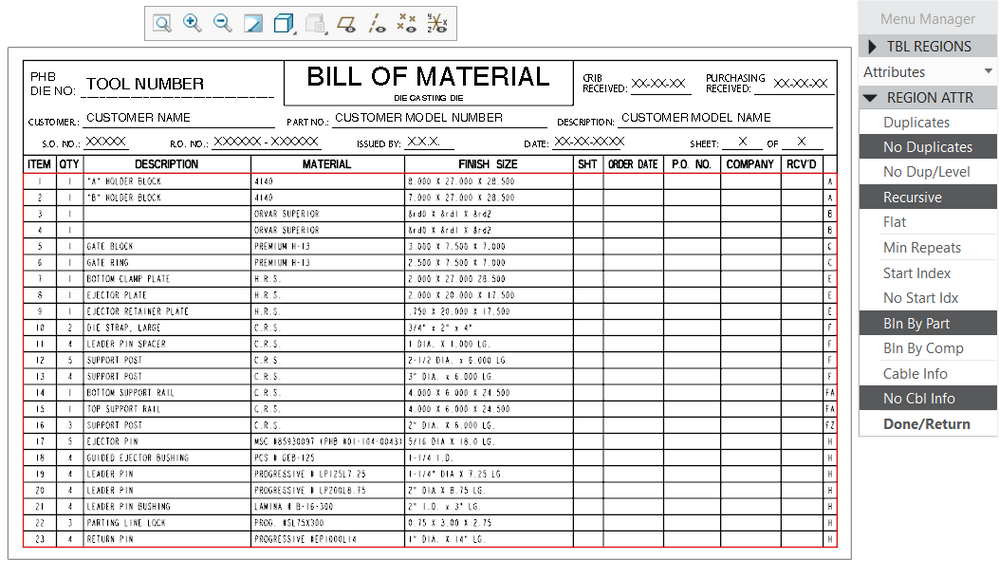

If you are using a repeat region in a drawing table, try setting the table region attributes to No Duplicates.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

If I do that a few things happen:

1) The number of entries goes from 58 to 53 - so more than just this part get's renewed / erased.

2) Instead of now those two entries (one with 16 pcs, the other one with 8 pcs) appearing, just the 16 pieces entry is appearing.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

@Spedex wrote:

If I do that a few things happen:

1) The number of entries goes from 58 to 53 - so more than just this part get's renewed / erased.2) Instead of now those two entries (one with 16 pcs, the other one with 8 pcs) appearing, just the 16 pieces entry is appearing.

Hi,

please attach picture of your BOM.

Martin Hanák

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Weights are only relevant if have assembly level modifications, such as flexible components (like springs and show in the model tree as in image below) or assembly cuts/holes that change a part at the assembly (2 washers in an assembly but one of them is cut so the weight of one of the washers is different than the other).

Do you have any assembly cuts in your model?

No repeat region relations makes it easier, means not custom modifications to your bom.

Have you tried adding another table on your drawing to see if it matches and to compare with your current BOM?

No duplicates (or no duplicates/level) in the table attributes fixed the problem but what other parts changed in the BOM? Were there other duplicates that you hadn't noticed?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi,

my suggestion follows.

Create new assembly test1 and assemble 3 Scheibe parts into it.

Create new assembly test2 and assemble 2 Scheibe parts into it.

Create new assembly test_main and assemble assembly test1 and assembly test2 into it.

Create drawing for assembly test_main and experiment with repeat region.

When you can work with the test drawing, go back to the original drawing.

Martin Hanák

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Ok I found the reason why it does not combine the two rows.

It is because those 16 pieces are directly in the assembly, the other 8 pieces of the same part are in a subassembly of a subassembly of the assembly.

ASSEMBLY (drawing)

- 16 pieces of the probem part

- SUBASSEMBLY

- SUBASSEMBLY

- 8 pieces of the problem part

I cannot drag and drop the 8 pieces of the problem part out of the subassembly like this:

ASSEMBLY (drawing)

- 16 pieces of the probem part

- 8 pieces of the problem part

- SUBASSEMBLY

- SUBASSEMBLY

Or this:

ASSEMBLY (drawing)

- 16 pieces of the probem part

- SUBASSEMBLY

- SUBASSEMBLY

- 8 pieces of the problem part

I think I would have to build them in again "fromt the beginning".

Or does somebody know another way?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Good to know the reason why something is happening.

I do not know of any way to combine entries in the BOM across sub-assemblies. The system either reports at a single level or all levels individually. Not sure if combining them could be done with a relation, but that might get tricky.

If the software won't let you move the disk components from the sub-assembly to the top assembly, your only choice is to remove them from the sub and add them back in at the assembly level.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

@Spedex wrote:

Ok I found the reason why it does not combine the two rows.

It is because those 16 pieces are directly in the assembly, the other 8 pieces of the same part are in a subassembly of a subassembly of the assembly.

ASSEMBLY (drawing)

- 16 pieces of the probem part

- SUBASSEMBLY

- SUBASSEMBLY

- 8 pieces of the problem part

I cannot drag and drop the 8 pieces of the problem part out of the subassembly like this:

ASSEMBLY (drawing)

- 16 pieces of the probem part

- 8 pieces of the problem part

- SUBASSEMBLY

- SUBASSEMBLY

Or this:

ASSEMBLY (drawing)

- 16 pieces of the probem part

- SUBASSEMBLY

- SUBASSEMBLY

- 8 pieces of the problem part

I think I would have to build them in again "fromt the beginning".

Or does somebody know another way?

Hi,

try switching repeat region from Recursive to Flat.

If you can please save table containing repeat region into tbl file and upload it.

Martin Hanák

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Martin,

Doesn't FLAT only report the BOM items in the top-level assembly? Documentation points to that being the case.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

@BenLoosli wrote:

Martin,

Doesn't FLAT only report the BOM items in the top-level assembly? Documentation points to that being the case.

I am sorry, I was shooting blind.

Martin Hanák

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It is important that your model is build the way you plan on documenting it. If you are randomly placing components in different levels of assemblies, it will be much more difficult.

The success of drag and drop of components from one assembly to another is very dependent on how the references of the components you are moving.

If you only want the components of the top level assembly to show, you should set your bom table attributes to FLAT, as Martin suggested.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Fixed it in the end by deleting them and building them in again.

Thank you everyone for helping.

Greetings

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

it is a switch that has multiple configurations depending on panel thickness. I have two instances of this switch which is displaying two line items in the BOM when it should be one line item with a quantity of two. Both of these switches of of the SAME configuration. Other configurable parts work just fine. For example I have a ton of rivets, MS20426 with configurations for different lengths.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you so much for your answer really you help me a lot .