Community Tip - Did you get an answer that solved your problem? Please mark it as an Accepted Solution so others with the same problem can find the answer easily. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Order of BOM balloons & items in table

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Order of BOM balloons & items in table

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Order of BOM balloons & items in table

Can you control a table and balloon items which can be fixed the same number every time you do a new assembly drawing? E.G part number 001212-08 will always be item 314 in the table and the balloon item and then show the same with QTY underneath.

- Labels:

-

2D Drawing

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

There is a way to do this with component parameters. See https://www.ptc.com/en/support/article?n=CS197902

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

After reading your question again I think it might be better to use a 'normal' parameter instead of component parameters. This would let you set it one time and then display the same value everywhere it's used in any assembly (assuming your repeat region table is set up correctly.) You would just have to make sure you never reused this same number in any other model or you could end up with duplicate numbers in the same table.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I am not I explained myself very well

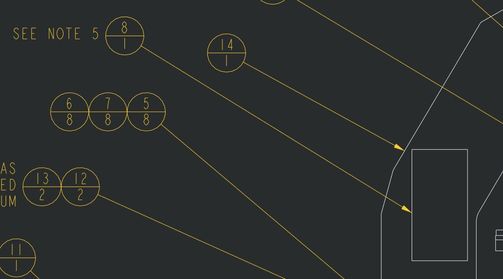

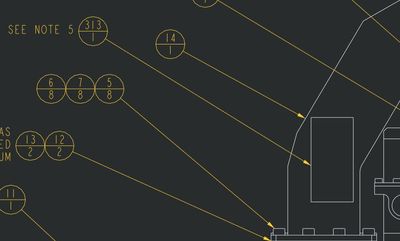

You place a part list (repeat region) on to the drawing and it the parts in order of part number 1 to 14

You also added Balloons to the drawing driven by the parts list (repeat region)

To part number 001212-08 to item 313 and 001212-09 to item 314 you have to fix index to be shown like the below image (Which can be done on it's own but the balloon does not change)

What trying to end up with is the below but when ever you bring in a part list at the start it automatically fixes certain part number to certain item numbers and the balloon changes as well.

What I think I am trying to ask is can fix index before putting a parts list (repeat region) on a drawing?

Thank you for your kind help in advance.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The problem you will have is that you are using 2 different parameters in your BOM table and in the balloons.

The internal find number is being used in the balloons and a normal repeat region.

You will have to do some repeat region relations to get your stored find numbers into the list for parts that have a findnumber and yet use the internal one if they do not.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I am only trying to do this on a small amount of numbers which refer to other documents.

If you have the same number every time write the other document is a lot quicker to construct.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Martin

I have a common parameter, that I give to any part or assemblies I make.

I called this parameter POSITION.

Then, when I make a repeat region, in one column I set asm.mbr.POSITION.

The repeat region is ordered according this parameter, so balloons too.

In the same drawing, or in other, if I want to have the same number, I just refer to POSITION.

For example, if I put a note or balloon I just have to set "&POSITION" in the string.

Of course, you have to be sure that POSITION are not equal.

This concept has been explained before by TomU.

I only put an example.

Hope to have been helpful.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This is generally considered a bad idea.

Your example is with a high number, but what about lower numbers, like 1-100?

The 1/4-20X.75 HHCS is to always be item 96?

That would use a lot of numbers if you used a fixed line item for every part.

I have over 2 million parts in Windchill and 11K+ in hardware family tables.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Here's how to do this:

1. Go into Repeat Region Relations. Add the following relation:

pos = rpt_index

if exists("asm_mbr_position") == true

pos = asm_mbr_position

endif

This will create a new parameter called "pos", assign it the index value, then, if the part has a parameter called "position", set the "pos" value to that instead.

2. Add a new column to your Repeat Region. This column should hold display the parameter "&rpt.rel.pos". This is in ADDITION to the "index" column. The problem is that for some reason Creo doesn't create the index unless it's displayed in the Repeat Region. So if you remove that column, your relation is going to fail, since it can't find the "rpt_index" parameter. To avoid this, remove the header of that column, set the text size of the entire column to 0.0001, and likewise set the column width to 0.0001. The column should now be pretty much invisible.

3. Select the table (make sure to select the entire table) and Edit Definition/Properties (depending on your version). Set the BOM ballons to display your rpt.rel.pos, instead of rpt.index.

Now you have a repeat region which will use your Position parameter if it exists, and just use a normal index if it doesn't. Note that it doesn't ensure there's no overlap, so if you have enough parts, you could get two parts with the same index this way. There's no simple way to avoid this (there might be a complex way), so I'd recommend to just keep the fixed position numbers high enough that it won't happen.