- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Parameter driven components and the replace co...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Parameter driven components and the replace components feature

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Parameter driven components and the replace components feature

Hi!

I'm a new creo convert, so still learning my way round. I've got an assembly, which comprises of essentially a pair of cylinders that extend, and a framework linking them. The cylinder comes in three different length variations, but the width between the cylinders varies.

At present each product variation is created by parametrically controlling the distance between the cylinders which drives the sections of frame between. However at present to swap between the three cylinders the sub assembly is swapped over via using the 'Replace Selected Components or UDF' function, and this works perfectly at the moment.

However, I want to try and automate the generation of the cover which goes over said frame, and at the moment the width is done parametrically, however the length requires manual intervention. I've already got inside each of the cylinders a parameter for the cover length which in the top level works, but as soon as I change the cylinder this link is broken and it won't find the (same) parameter in the new assembly.

Is there a way to make this work?

- Labels:

-

Assembly Design

-

Flexible Modeling

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

just to add, the reason why it is not working is because the session ID of the parts is different, if I correct this then it works... but I kind of hoped not to have to do that

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Try to move the parameter from model level to a component level.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I'm not entirely sure what you mean.

For now I'm still just manually updating the Session ID everytime I do this

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

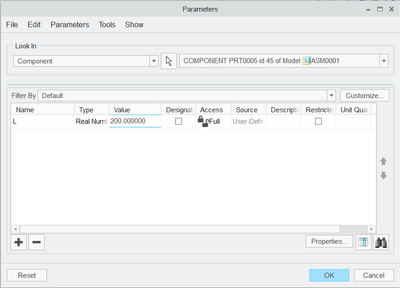

If you create a parameter at a component level. In assembly relation you can use this parameter asmpar = L:FID_45, where 45 is a component ID. In this case after model replacement the relation will be updated automatically.

But, in close look, this not help you.

Can you create a cylinder variation as a family table? If replace the model from family table, the model session ID will be updated automatically too.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Whilst it's not a "Quick Fix" I think Family table will be my only next option, thanks.