Community Tip - Need to share some code when posting a question or reply? Make sure to use the "Insert code sample" menu option. Learn more! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Patterning Rounds Feature

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Patterning Rounds Feature

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Patterning Rounds Feature

New Creo 5.0.4 user

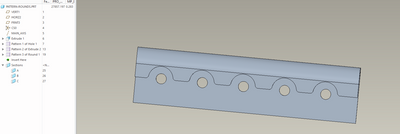

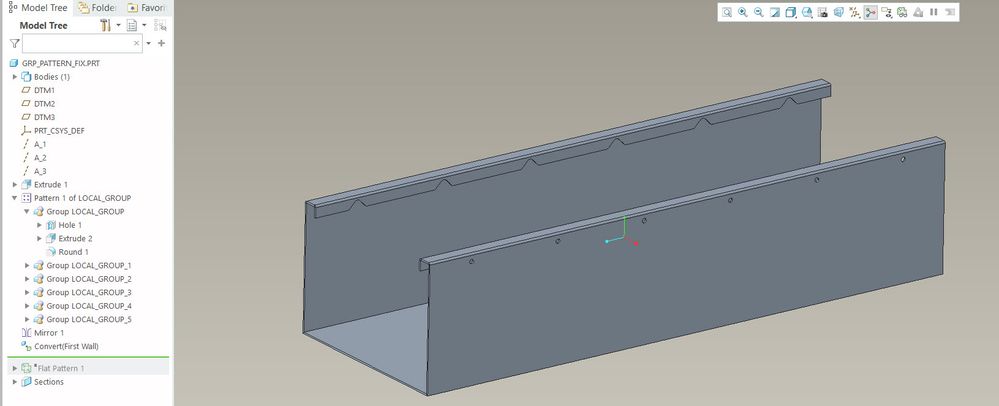

I have a hole pattern and created some access cuts on a sheet metal part (see picture below). I rounded/filleted the edges (highlighted in green). The cut feature patterned easy enough following the hole pattern, but I cannot pattern the rounds (greyed out).

Outside of adding the fillets to the cutout sketch, is there a way to pattern this? Selecting all of the patterned edges for the round feature seems tedious, and I would guess there would be issues if the hole quantity changed.

Thanks,

Greg

- Labels:

-

General

-

Sheet Metal Design

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I don't know about this specific use case but if I want to pattern rounds with features, I typically will get one area done completely, group those features, then pattern the group.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I was excited to try out your solution, but unfortunately I got regeneration errors. I tried grouping the round with the cut 1st, and then I removed the original hole pattern and tried grouping all 3 features in 1 pattern, same error. ☹️

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Grouping will work in most cases like this as @StephenW posted. The most likely issue is that your references are being lost when patterning. Without inspecting the features, it is hard to tell. If you post the model or a similar one with your grouping of the features someone may be able to troubleshoot it.

I have posted a model for reference (Creo 4) that utilizes a pattern scheme similar to what you want. In this test case a group is not used intentionally for debugging purposes. So you will see 3 patterns rather than one pattern of a group. Sometimes this is necessary depending on the references needed and reference patterns are used for the subsequent patterns.

It is also using intent references, but it should give you an idea of how to handle your design intent. The intent refs are used to make the pattern much more flexible so it will turn the corner on the shape. You can demonstrate this by increasing the # of instances in pattern 1 from 5 to 6 instances.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Creo 4

I just did it and didn't have any problems without a group and again with the group.

changed pattern qtys and it all just worked fine.

If you can, attach a file.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

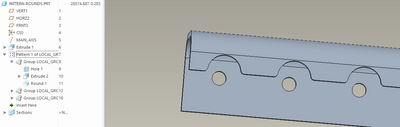

I'm attaching the model. I've eliminated the features that were not relevant to this issue. I think the issue is the double mirror. As I said, I have other cut outs and tabs not shown in the attached. I'd rather mirror the body than collection of features, but maybe that isn't the creo way?

Thank for your time.

(edit: I screwed up the holes removing features, I'll repost model in a few minutes)

(edit2: ok, here's the fixed model that is having the specific topic issue)

CREO 5

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

As I had suspected the round edge references are failing in your model. The issue is with the intent edges of the rounds (.125 R) on the cut. In your part, the intent edges as defined internally by Creo are not playing nicely with the pattern. You have no direct control over that. Sheetmetal parts have historically not been compatible with core modeling features in some cases.

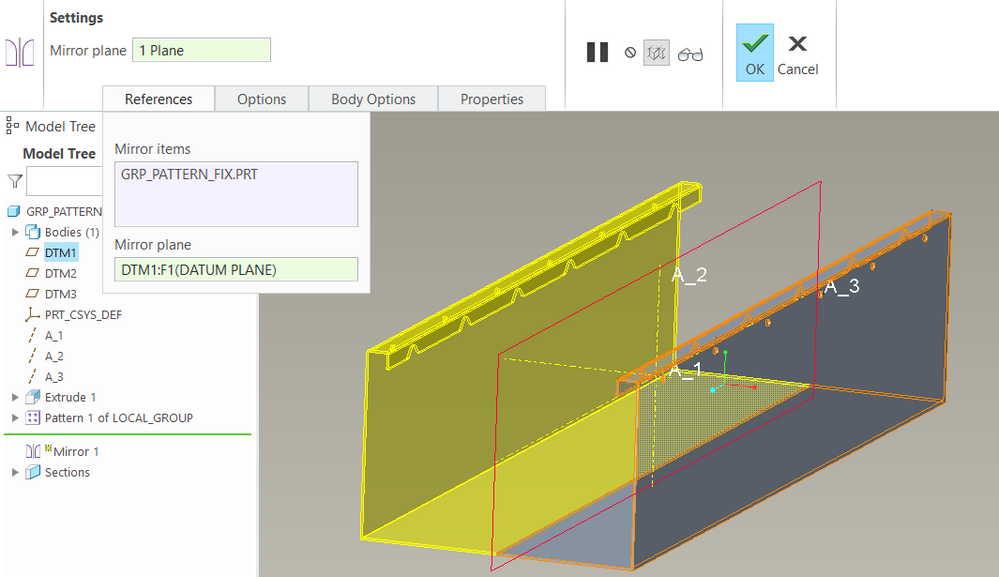

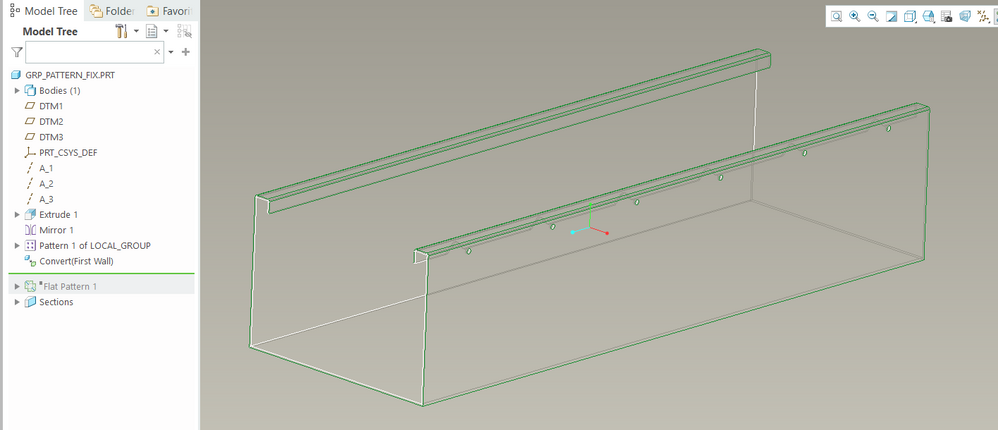

I have posted a part that does pattern the geometry as you desire and uses the mirror of the geometry as you intend. I created a solid part and then converted it to sheet metal. This represents one way to generate the model with the geometry and pattern you specified. I hacked this together fast to test it.

The model is Creo 7. Model tree shown in case you don't have Creo 7.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Your pattern happens before the mirror. What happens when you do it after (and on the mirrored side)? (I'm not mirroring the pattern in this case).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

That is a mirror of the part geometry and not a mirror of features.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

What I'm saying is your pattern feature happens 1st. Have your feature happen after the mirror.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Pattern after the mirror.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Very interesting. It could very well be a sheet metal issues as you say. I deleted them in the attached, but I have an unbend, some extruded cuts across bends and then a rebend feature not shown (amongst other things). Although a valid work around for other scenarios, I don't see remodeling this as a solid then a conversion as a solution. That is not to say I don't appreciate the efforts though. 😉

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I think it is a bug and should be submitted to PTC tech support.

I always default to using a solid part model and then convert to sheet metal whenever possible. In my experience this type of thing (bug with core functions) is not uncommon in sheet metal mode. In most cases I can create the geometry faster as a solid or surface model than if I start with a sheet metal part so that is the prime consideration.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks, I will submit this.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You're welcome.