Community Tip - Need to share some code when posting a question or reply? Make sure to use the "Insert code sample" menu option. Learn more! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Performing a Drop test analysis in Creo-simulate f...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Performing a Drop test analysis in Creo-simulate for a plastic component.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Performing a Drop test analysis in Creo-simulate for a plastic component.

Hi All,

Can any one help me out in,How a drop test analysis can be done in CAE using creo simulate and what are parameters to be considered while performing the analysis?

Thanks,

Anoop Krishna.

- Labels:

-

General

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Simple way is to add force on point of impact that is equal of mass*gravity.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Davor,

Thanks for your reply,

Can u explain in a step by step procedure to me,As i was new to Creo-Simulate.

Attached a file,So that u can do a drop test analysis on it.

Thanks

Anoop Krishna M.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

hello,

In the basic knowledge of PTC there several explanations in shock conditions as well as a model, it is for an older version 2000i.

Kind regards.

Denis.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Denis

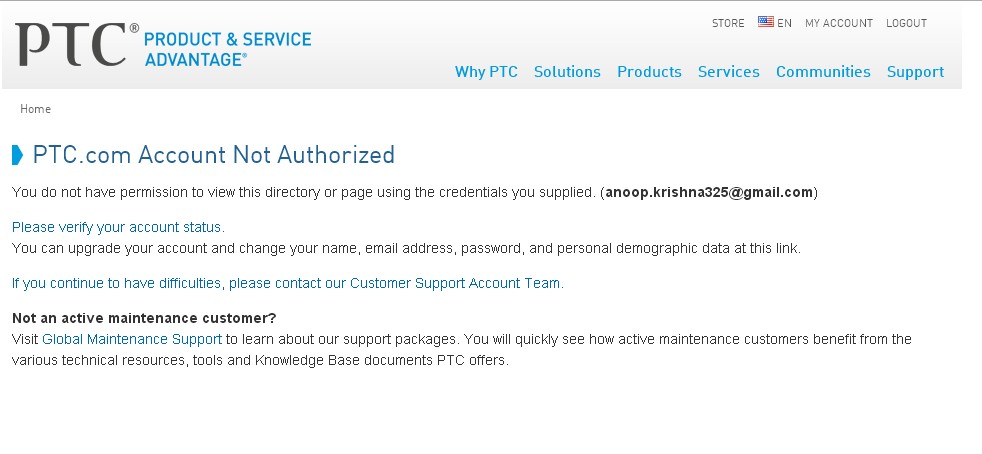

When i am trying to open the link u provided,It is showing,as shown in the attached picture.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

hello,

Watch your private messaging.

Kind regards.

Denis.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I completed my design of the plastic enclosure,After moulding of the component,it should undergo a drop test manually,If there is any issue with the design arise at that time we should under go a change in mould,which is expensive and time taking.

So i want to perform a drop test here in Creo/Simulate,So that it is very helpful to me.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

hello,

Here is a document, but not in English ..

Kind regards.

Denis.

http://cae-forum.de/sites/default/files/NSF_2012_Jakel_Schockanalysen.pdf

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

As written above :

Shock on a pager.

In the basic knowledge of PTC there several explanations in shock conditions as well as a model, it is for an older version 2000i.

Kind regards.

Denis.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Take Density of the material as 1.2g/cc.

With Regards,

Anoop Krishna

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

hello,

Here is a document.

Kind regards.

Denis.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I don't think Davor's suggestion is quite what Anoop is looking for - that would just represent the static weight of the component resting on the chosen point. An impact analysis is going to require an energy component (m × g × h).

If the impact is assumed to be taken on a single, fixed point then a starting point would be first analyse the part with a unit force to estimate the linear stiffness, then work out the force required to convert the gravitational energy into spring energy (m g h = 1/2 k x^2). By scaling the stress results of your initial analysis you can then estimate whether this force is enough to cause the material to yield or break.

A more complex analysis than that will probably require contact and non-linear materials - I don't even know whether a full time-domain impact analysis is possible in Mechanica, but hopefully one of the experts will be along shortly to tell us!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yea, I stand corrected. Forgot to include height of fall.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I've tried what is suggested in this two papers:

- http://www.google.ch/url?sa=t&rct=j&q=&esrc=s&source=web&cd=4&cad=rja&uact=8&ved=0CDMQFjAD&url=http%3A%2F%2Fpfproe.pl%2F…

- http://support.ptc.com/cs/fr_21/howto/mst2742/mst2742_f.htm?_ga=1.255711937.857534450.1425991567

but I don't understand why, in each of them, the point of impact is not where we have the maximum stress.

Rather, it seems that there is no stress (Von Mises) near the area of imposition of the load.

Furthermore in the PTC examples you set the load as a pressure of 1 MPa; ok but nobody talk about the area. This is because you let the load change by the function specified in the Dynamic Time Analysis: this function is obtained from a previous analysis, e.g. in Mechanism, as a force curve (Newton) in function of time. Using the 3D Contact in mechanism, you can estimate also the variation of contact area.

So in Mechanica/Simulate you impose the force curve on an area that you can take as the max or the average of the value of the Motion/3Dcontact measure.

But the load is a pressure, not a force, so in my opinin you have to impose a pressure of 1 [MPa]/Area [mm^2] and let vary this load by the function.

In this manner you impose the real force of the curve.

What do you think?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Is the best way to still do a drop analysis via Creo Simulate? All of the links in this thread are dead, does anyone have a good tutorial besides:

https://www.ptc.com/en/support/article/CS76643

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

If you need a high fidelity simulation of an impact or collision event you need a nonlinear capable sim code. I do not think Creo simulate is the best option for this. You will need to be able to deal with contact elements that separate and come back together as one example where I think Creo is lacking. I could be wrong if they added functionality but the last time I looked at the tool it could not support these things.

ABAQUS is the solver used in most of the designs I have worked on that had impact simulation done on them. It is $$$$$ and you need someone skilled in the use of it in order to get an ROI.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

thanks!