Community Tip - You can subscribe to a forum, label or individual post and receive email notifications when someone posts a new topic or reply. Learn more! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Problem with the solder combiner (#Combine)

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Problem with the solder combiner (#Combine)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Problem with the solder combiner (#Combine)

Hi,

I'm starting to use the welding module.

I have a problem:

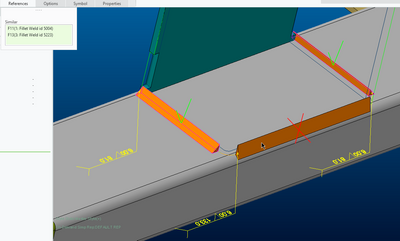

I created three fillet welds, I try to combine them but I can only combine two, selecting the third one this message appears: "The groove/butt weld must be positioned higher in the Model Tree than the fillet weld."

Has this happened to you too?

Have you solved it?

Thank you.

P.S. I'm using Creo 9.0.2.0

Solved! Go to Solution.

- Labels:

-

Weld Design

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I asked support to the PTC Esupport and they answered me like this:

"I got an answer from our R&D.

The reason combine feature rejects the combination is that value of X_SECTION_AREA is different despite having same legs. The X_SECTION_AREA for solid welds defined as volume / trajectory length which is not well defined for non linear trajectory, which is the case here. We understand that behavior is not ideal but we consider reviewing it in a future release."

The operator, very cordial, then added:

"Alternatively and for this specific case, you can proceed by converting the solid welds to surfaces and manually forcing the value of the « weld cross sec » to an identical value for both welds OR create only one weld feat with 2 sets inside."

For now I consider the answer as a solution, hoping that soon they can better manage the situation.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Are they three separate weld features or one?

Have you tried playing with the weld bead size to see if its a problem with that outside radius you have?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

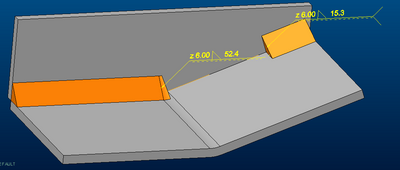

That's three separate welds. Three fillet welds with Z6.

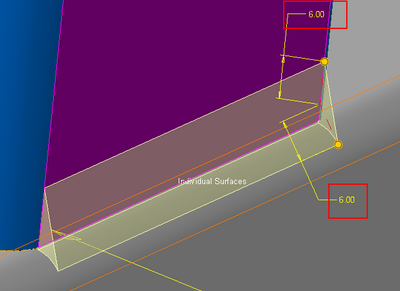

By converting the dimensions of the problematic weld from Z to Z1xZ2, the program offers me this dimension, resolved in a curious way.

Even changing the values did not solve the problem.

I also tried to vary the value of the underlying radius but I didn't solve it.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Did you try making the welds as a single feature? You cab pick more than one surface when you are defining your weld so it wraps around the geometry. Sounds to me that this is what you are trying to make them do.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yes, it could be acceptable,

defining the three welds in a single feature is a path that I evaluated, but I didn't like it because the total length of the three beads is reported in the note that appears.

At this point I could remove the indication of the length of the cord from the note and quote the lengths in the drw with the classic quotas, but before taking this path I wanted to ask if it is possible to solve the problem of the cord.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

CASE 2:

Another situation similar problem.

Define two simple fillet welds by capping an end joint of both welds.

If a joint of one of the two welds affects the radiused surface, the message "The groove/butt weld must be positioned higher in the Model Tree than the fillet weld." appears. and I can't combine the two welds.

I attach the example files.

I hope someone joins the discussion to express their experience on the matter and perhaps a solution.

Thank you.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I asked support to the PTC Esupport and they answered me like this:

"I got an answer from our R&D.

The reason combine feature rejects the combination is that value of X_SECTION_AREA is different despite having same legs. The X_SECTION_AREA for solid welds defined as volume / trajectory length which is not well defined for non linear trajectory, which is the case here. We understand that behavior is not ideal but we consider reviewing it in a future release."

The operator, very cordial, then added:

"Alternatively and for this specific case, you can proceed by converting the solid welds to surfaces and manually forcing the value of the « weld cross sec » to an identical value for both welds OR create only one weld feat with 2 sets inside."

For now I consider the answer as a solution, hoping that soon they can better manage the situation.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

P.S. They also created a technical article about it: https://www.ptc.com/en/support/article/cs390973